Fluoroborate exchange crystallization recovery technology for cephalosporin fluorine-containing waste liquid

A fluoroborate, potassium fluoroborate technology, applied in tetrafluoroboric acid, boron halide compounds, ammonium chloride and other directions, can solve the problems of strict emission control, corrosion of equipment, serious problems, etc., to avoid corrosion, easy operation control, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

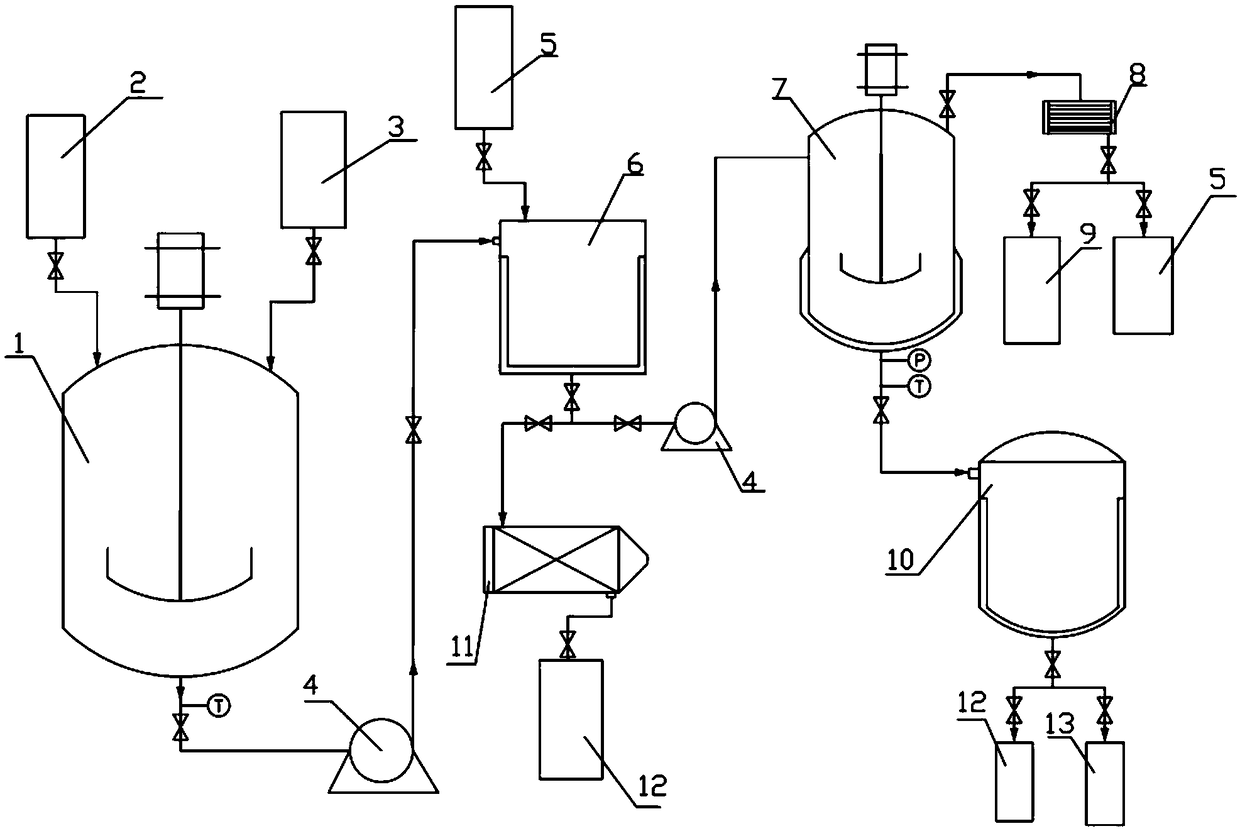

Image

Examples

Embodiment 1

[0026] (1) Add 8L of cephalosporin fluorine-containing waste liquid in the stirred tank, after measuring 5.7mol / L of fluoroborate, stir and add 10% ammonia water to adjust the pH to 7.0, then continue to add 3.4kg potassium chloride in the stirred tank to carry out salt For the exchange reaction, the temperature is 50°C, and the reaction is stirred for 2 hours. During the reaction, crystallization is continuously produced. After the reaction, the solid-liquid separation is carried out through a centrifuge to obtain the remaining waste liquid and solid potassium fluoroborate from which the fluorine-containing compound has been removed. The solid remains in the centrifuge and is washed with water, and washed twice. After centrifugal washing, wet potassium fluoroborate is obtained and then dried in a dryer. The drying time is 8 hours, and the drying temperature is 120°C. Finally, the pure product is collected; after determination of fluorine The recovery rate of potassium borate w...

Embodiment 2

[0029] (1) Add 10L of cephalosporin fluorine-containing waste liquid in the stirred tank, after measuring 8.3mol / L of fluoroborate, stir and add 20% ammonia water to adjust the pH to 14, then continue to add 7.4kg of potassium chloride in the stirred tank for salting For the exchange reaction, the temperature is 100°C, and the reaction is stirred for 2 hours. During the reaction, crystallization is continuously produced. After the reaction, the solid-liquid separation is carried out through a centrifuge to obtain the remaining waste liquid and solid potassium fluoroborate from which the fluorine-containing compound has been removed. The solid remains in the centrifuge and is washed with water, and washed twice. After centrifugal washing, wet potassium fluoroborate is obtained and then dried in a dryer. The drying time is 12 hours, and the drying temperature is 150°C. Finally, the pure product is collected; The recovery rate of potassium borate was 99.1%, and the purity was 99.2...

Embodiment 3

[0032] (1) Add 5L of cephalosporin fluorine-containing waste liquid in the stirred tank, after measuring 2.3mol / L of fluoroborate, stir and add 15% ammonia water to adjust the pH to 10.0, then continue to add 0.94kg potassium chloride solution in the stirred tank to carry out For the salt exchange reaction, the temperature is 80°C, and the reaction is stirred for 3 hours. During the reaction, precipitation occurs continuously; Continue to stay in the centrifuge and add water to wash, wash twice, get wet potassium fluoroborate after centrifugal washing, and then dry it in a dryer, drying time 9h, drying temperature 130°C, and finally collect the pure product; after determination of fluoroboric acid The recovery rate of potassium was 98.9%, and the purity was 99.0%.

[0033] (2) The remaining waste liquid after filtration can enter the rectification kettle to rectify and recover the organic solvent, the pressure is 0.1MPa, the temperature is 45°C, the organic solvent is condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com