Method for preparing positive electrode materials NCM811 with uniform particle sizes for lithium batteries

A positive electrode material, lithium battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of uneven particle size distribution, complex synthesis route, harsh synthesis conditions, etc., to avoid long calcination time, optimize the synthesis process, The effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The preparation method of a lithium battery cathode material NCM811 with uniform particle size is as follows:

[0033] Step 1) Precursor preparation, accurately weigh 1.3865 g lithium acetate, 4.0220 g nickel acetate tetrahydrate, 0.5083 g cobalt acetate tetrahydrate, 0.4951 g manganese acetate tetrahydrate, 2.2022 g resorcinol, 8.9 mL Formaldehyde solution was dissolved in 40 mL deionized water and 20 mL ethanol to form a mixed solution, stirred at a stirring speed of 1000 rpm for 2 h, then transferred to a polytetrafluoroethylene reactor, reacted at 85 ° C for 72 h, cooled Form a gel at room temperature, and freeze-dry at minus 40-60°C for 12 hours to obtain a solid precursor;

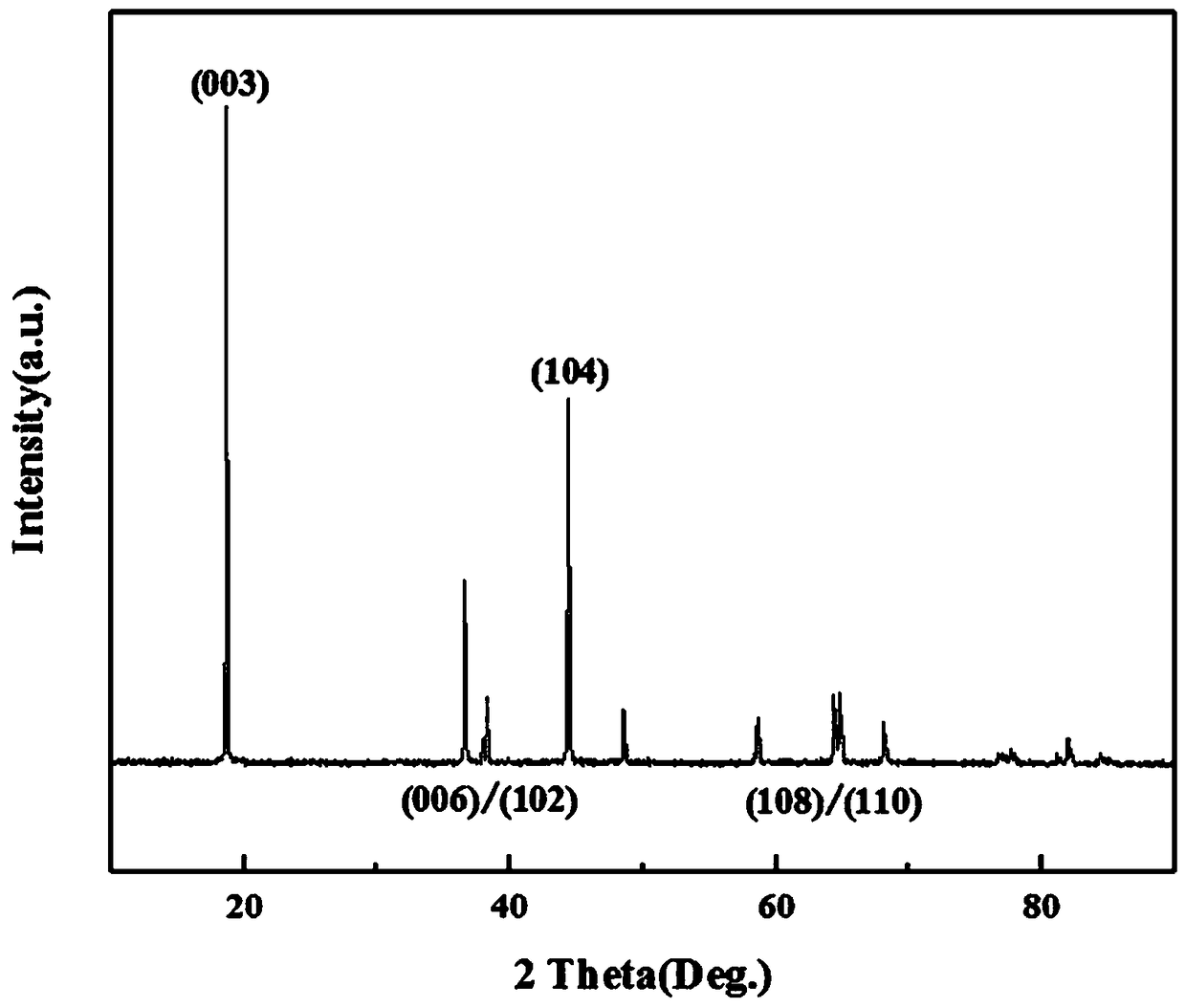

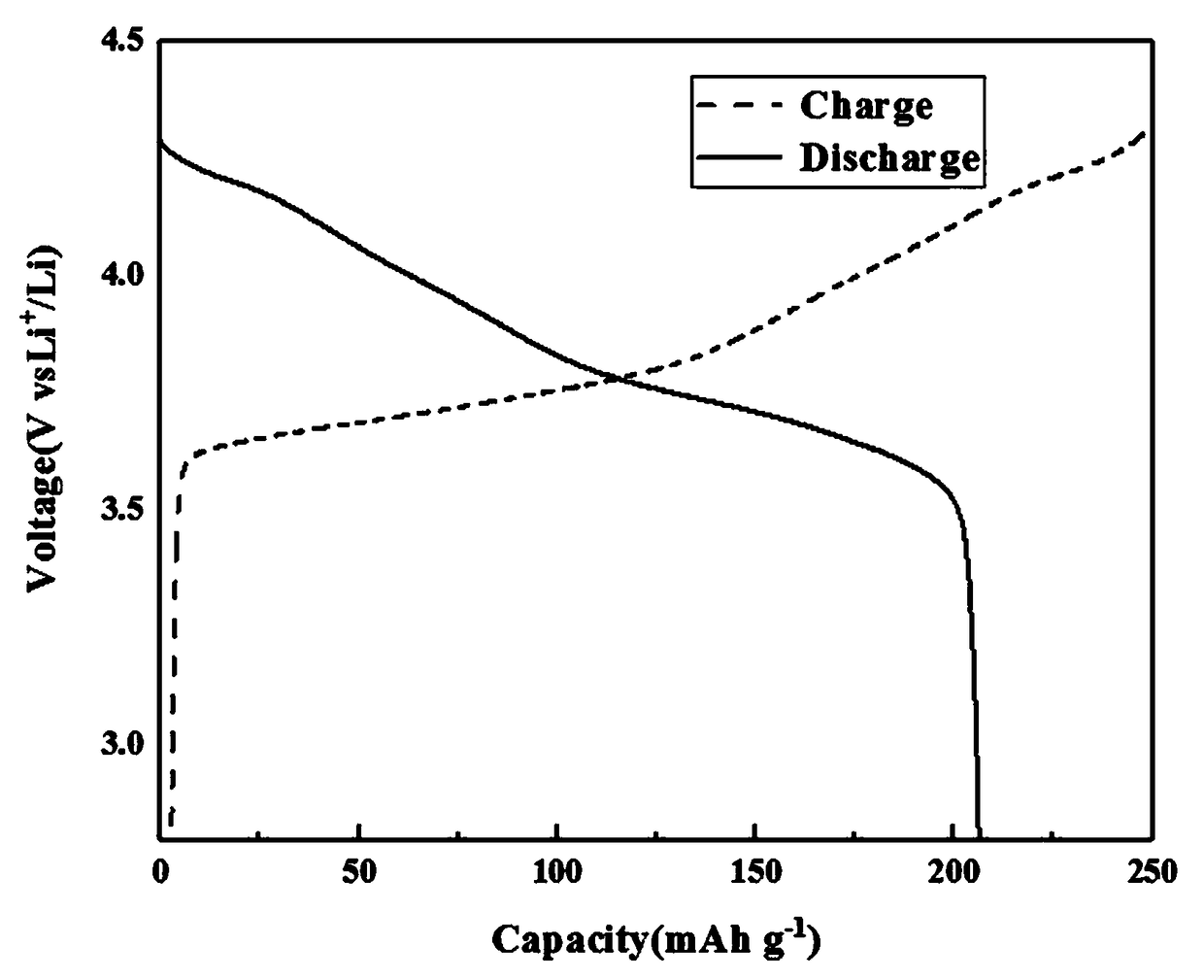

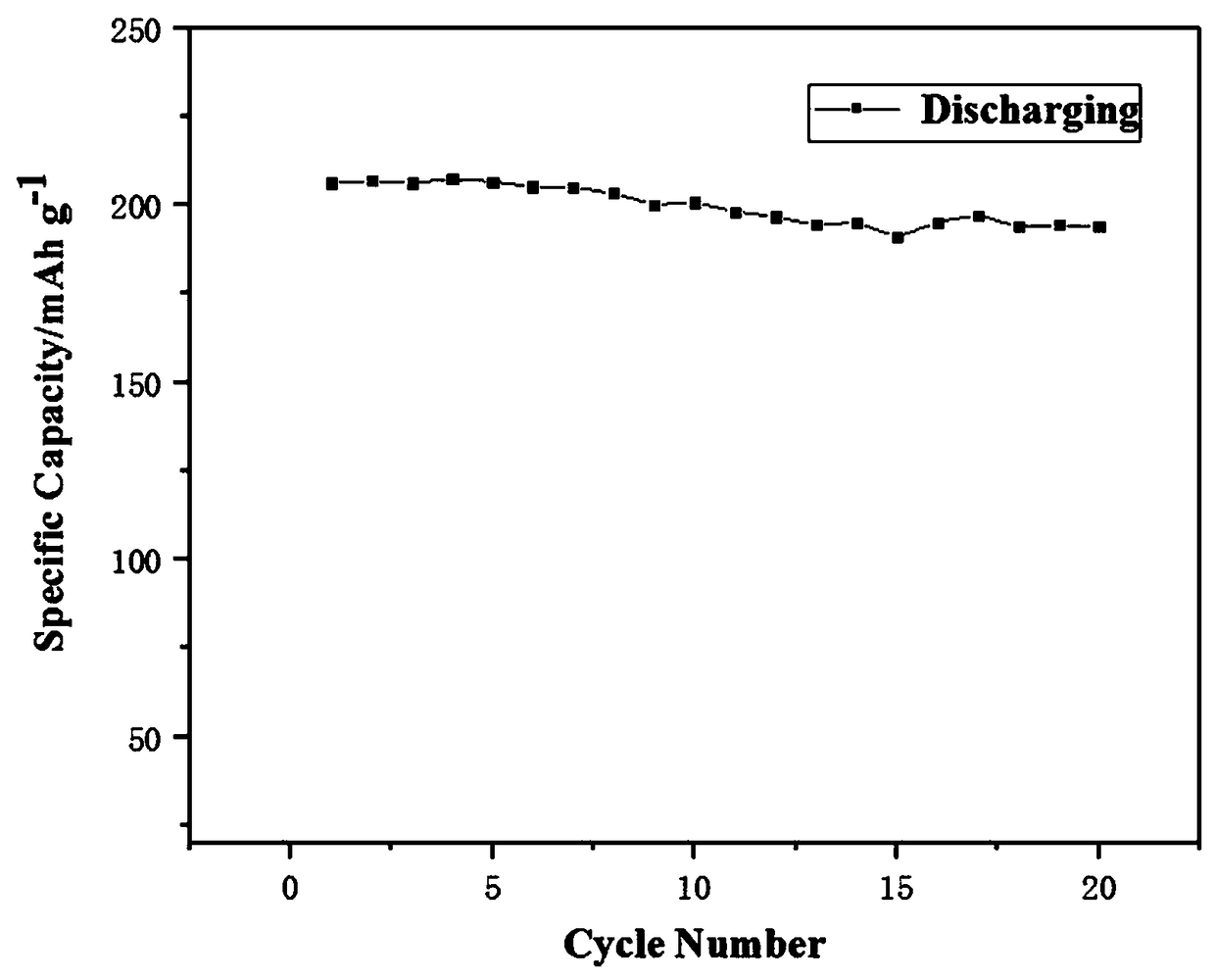

[0034] Step 2) Cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 For the preparation of the precursor, follow step 1) after grinding the precursor solid to obtain the precursor solid powder, in an atmosphere with an oxygen content of 100%, heat up to 450 °C at a heating rate of 5 °C / min for calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com