Preparation method of biochar/hydrotalcite-like compound

A biochar and hydrotalcite technology, applied in the field of soil remediation, can solve problems such as easy agglomeration, less research on contaminated soil remediation, and affect cadmium removal effect, etc., and achieve the advantages of cheap raw materials, simple preparation process, and good curing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

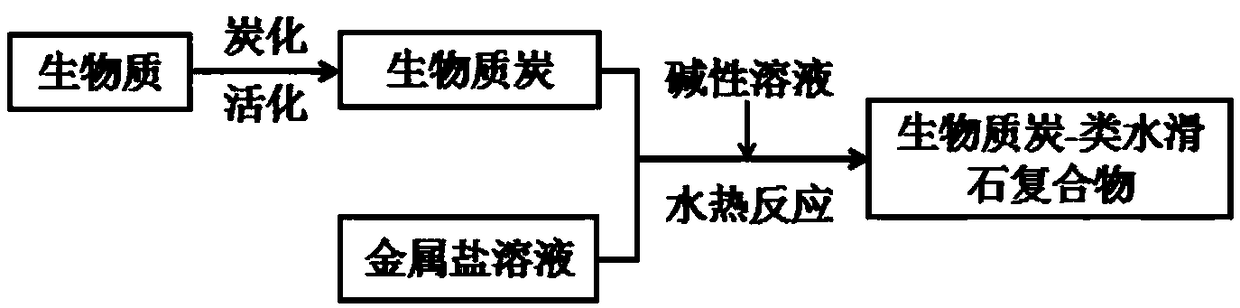

[0020] The preparation method of the composite material provided by this method comprises the following steps:

[0021] (1) Biomass pretreatment: wash the biomass with deionized water, filter, place in an oven to dry, and seal for subsequent use;

[0022] (2) Preparation of biochar: mix the biomass in step (1) with potassium hydroxide (mass ratio: 1:1-1:3) solution, stir in a water bath at 40-80°C for 6-12 hours, dry, Put it into a tube furnace for carbonization at 600-800°C for 1-2 hours, wash with water until neutral, and dry to obtain biochar;

[0023] (3) Preparation of the complex: Weigh 0.25-0.75 g of the biochar prepared in step (2), add it to 50-100 mL of a mixed solution of two metal salts with a certain molar ratio, and add the alkaline solution dropwise until the pH is 9-11. Finally, the obtained slurry is hydrothermally treated at 60-140° C. for 24-48 hours, centrifuged, washed with water, dried, ground, and sieved to obtain a biochar / hydrotalcite-like composite. ...

Embodiment example 1

[0031] Rice husks were used as biomass raw materials, washed, dried, crushed, mixed with potassium hydroxide solution at a mass ratio of 1:3, stirred in a water bath at 40°C for 8 hours, dried, reacted in a tube furnace at 800°C for 1 hour, washed with water until Neutral, biochar is obtained after drying.

[0032] Weigh 0.25-0.75 g of the prepared biochar, configure it with magnesium nitrate and iron nitrate (3:1 molar ratio) to form a mixed solution, add dropwise a mixed solution of sodium hydroxide and sodium carbonate until the pH is 9-11, Finally, the obtained slurry was hydrothermally reacted at 80° C. for 24 hours, centrifuged, washed with water, dried, ground, and sieved to obtain a biochar-hydrotalcite-like composite.

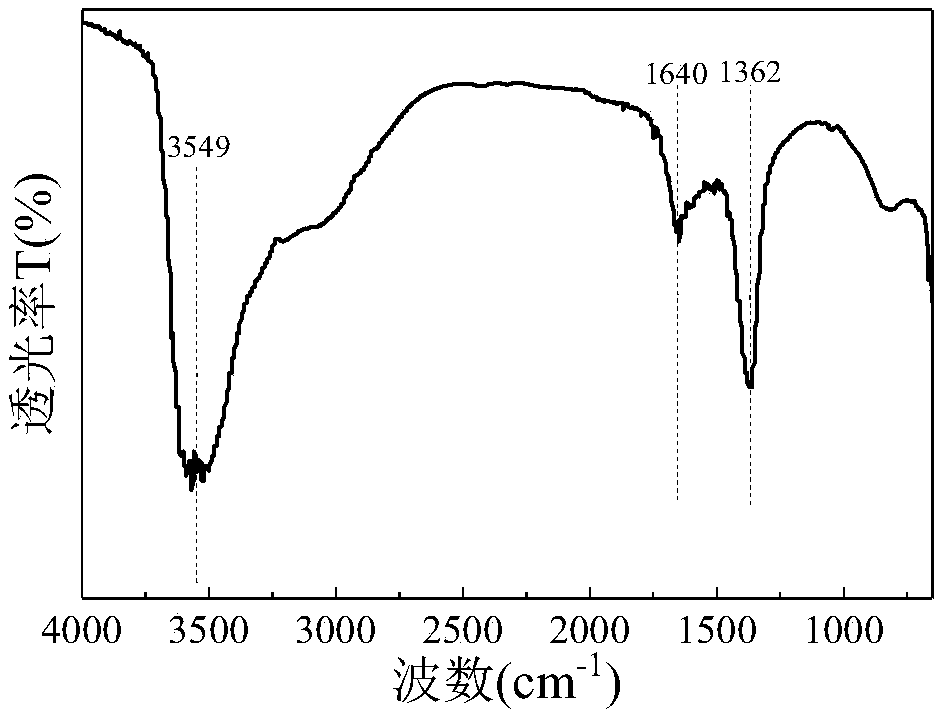

[0033] In wave number (cm -1 ) is the abscissa, the light transmittance T (%) is the ordinate, and the FTIR spectrum of the composite is drawn. Such as figure 2 Shown at 3500-3600cm -1 The absorption band at , represents the absorption peak of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com