Multi-shell-layer hollow-core-shell cubic structure type M1.8M'1.2O4@CeO2 composite material and preparation method thereof

An M1.8M, cubic structure technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. It can solve the problems of mass transfer and diffusion of chemical reaction molecules, and limit the practical application in the field of catalysis, so as to achieve the effect of simple and controllable synthesis method, improved diffusion speed and uniform size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

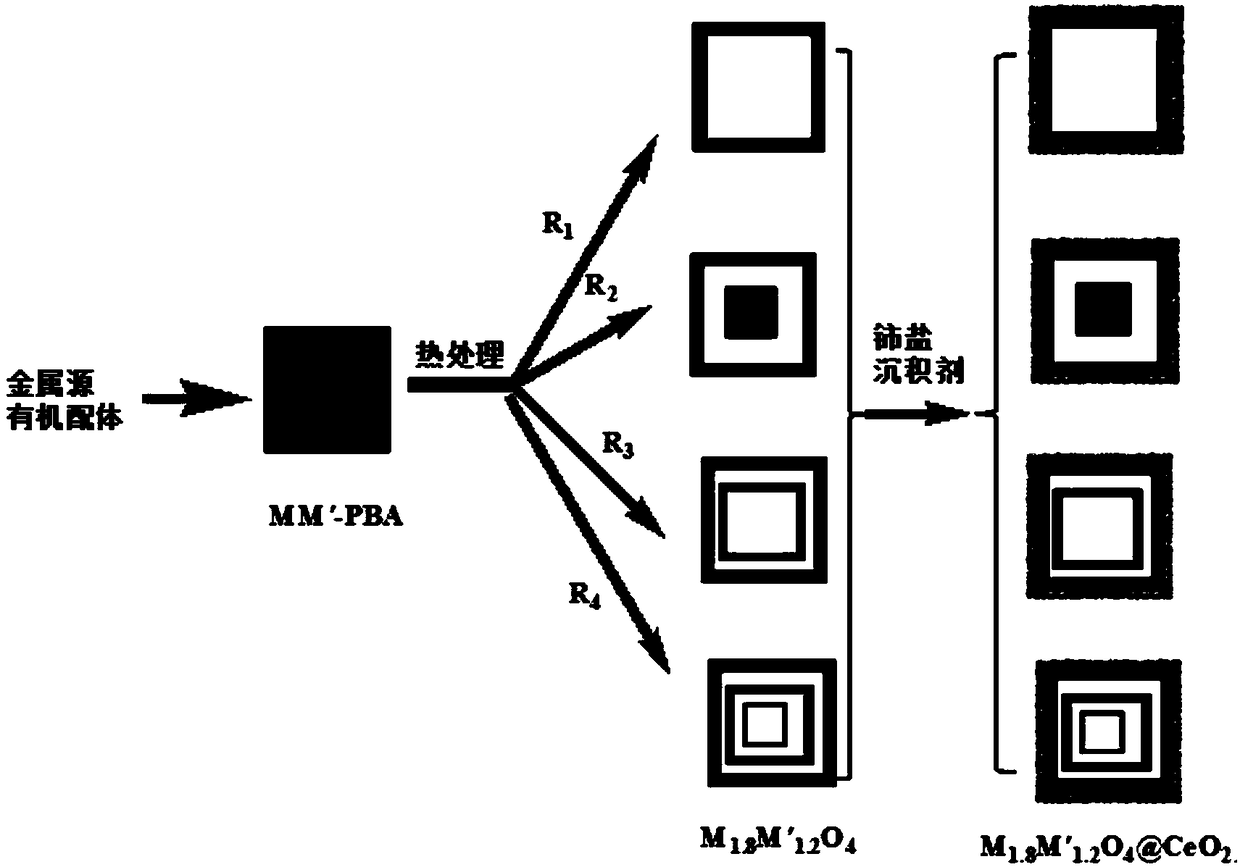

[0034] A kind of Mn with multi-shell hollow core-shell cubic structure 1.8 co 1.2 o 4 / CeO 2 The preparation method of composite materials, the technological process is as follows figure 1 shown, including the following steps:

[0035] (1) Synthesis of Prussian blue-like MnCo-PBAs cubic structure:

[0036] Weigh 0.245g (1mmol) of manganese acetate tetrahydrate and 1.5g of polyvinylpyrrolidone, dissolve them in 90mL ethanol-water mixed solution (ethanol:water=2:1, V / V) to form solution A; weigh K 3 [Co(CN) 6 ] 0.166 g (0.5 mmol) was dissolved in 60 mL deionized water to form solution B, and solution B was added dropwise to solution A under magnetic stirring, and after continuous stirring for 30 min, aged at room temperature for 24 h; centrifuged, washed, and dried to obtain the scale Uniform Mn 3 [Co(CN) 6 ] 2 (MnCo-PBA) cubic structure material;

[0037] (2) Mn 1.8 co 1.2 o 4 Synthesis of a single-shell hollow cubic structure:

[0038] Put the porcelain boat with...

Embodiment 2

[0045] Prussian blue-like MnCo-PBAs cubic structure, Mn 1.8 co 1.2 o 4 Egg yolk-eggshell hollow cubic structure and CeO 2 The synthesis steps of the assembly of the shell are the same as in Example 1. The difference is that in Mn 1.8 co 1.2 o 4 During the synthesis process of the egg yolk-eggshell hollow cube structure, the heating rate of the muffle furnace was set at 10°C / min, the reaction temperature was 300°C, and the holding time was 4h; 2 During the shell assembly process, 0.5 g of cerium nitrate was added, and the reaction was refluxed at 80° C. for 2.5 h.

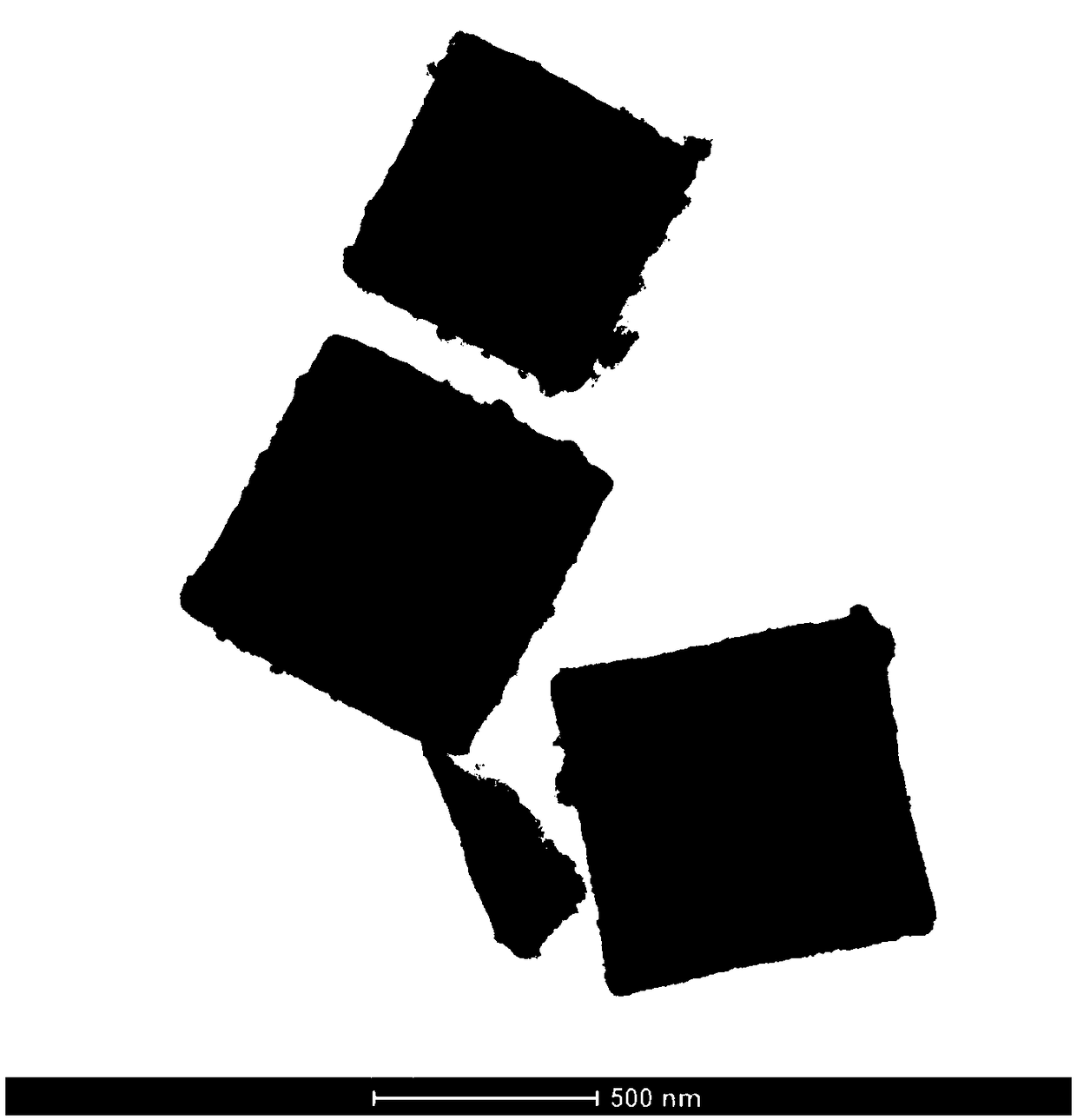

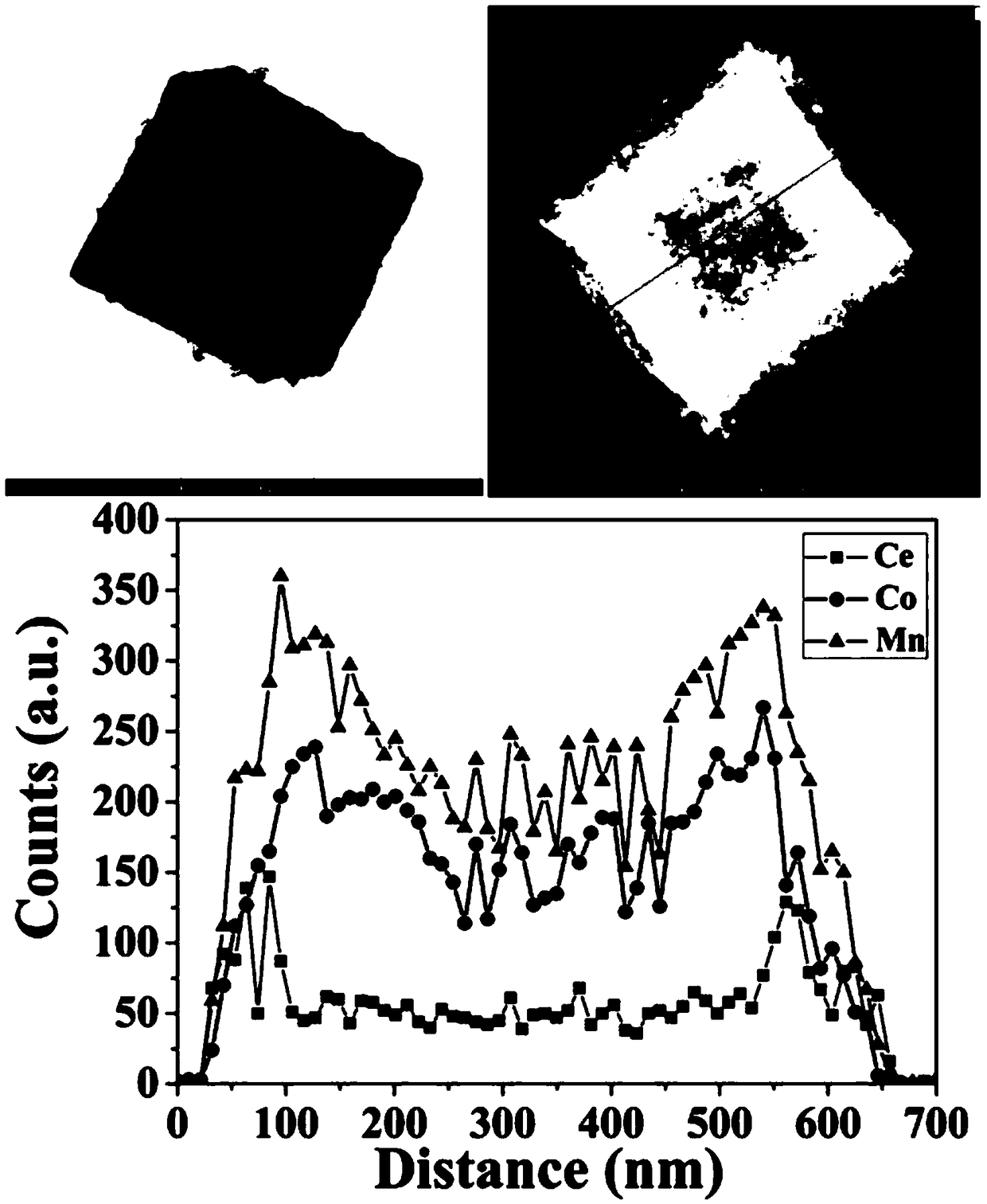

[0046] The transmission electron microscope TEM picture ( Figure 4 ) shows that Mn 1.8 co 1.2 o 4 @CeO 2 The composite oxide has an egg yolk-eggshell hollow cubic structure, the outside is a hollow cubic box, and the center is a solid cube. The average size of the egg yolk-eggshell hollow cubic structure is 500-600 nm, and the surface is uniformly covered with nanocrystalline particles. CeO 2 Shell, Ce...

Embodiment 3

[0049] Prussian blue-like MnCo-PBAs cubic structure, Mn 1.8 co 1.2 o 4 Double-shelled hollow cubic structure and CeO 2 The synthesis steps of the assembly of the shell are the same as in Example 1. The difference is that in Mn 1.8 co 1.2 o 4 During the synthesis process of the double-shell hollow cubic structure, the heating rate was set at 25°C / min, the reaction temperature was 600°C, and the holding time was 0.5h; 2 During shell assembly, 0.75 g of cerium nitrate and 1.5 g of urea were added, ultrasonicated for 40 min, and refluxed at 80°C for 3 h.

[0050] The transmission electron microscope TEM picture ( Figure 6 ) shows that Mn 1.8 co 1.2 o 4 @CeO 2 The composite oxide is a double-shell hollow cubic structure with a size of 500-600nm, and the surface is coated with CeO composed of nanocrystalline grains. 2 Shell, CeO 2 The shell thickness is 30-50nm.

[0051] Catalytic performance is the same as embodiment 1, and test result shows, the temperature (T 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com