Vanadium-free denitration catalyst for arsenic-containing flue gas and preparation process thereof

A denitration catalyst and technology for preparation process, applied in the field of vanadium-free denitration catalyst and preparation thereof, can solve the problems of reduced denitration efficiency, reduced amount of adsorbed arsenic, blocked microscopic pores, etc., so as to achieve inhibition of deposition and accumulation, development of pores, and slowing of deactivation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

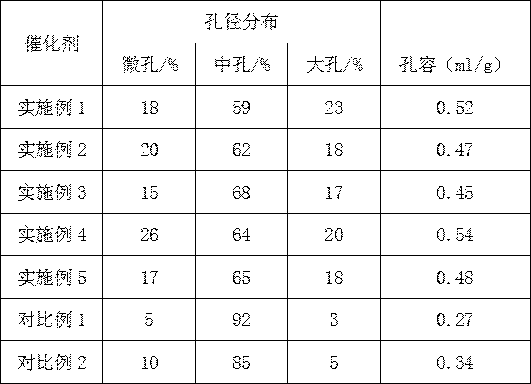

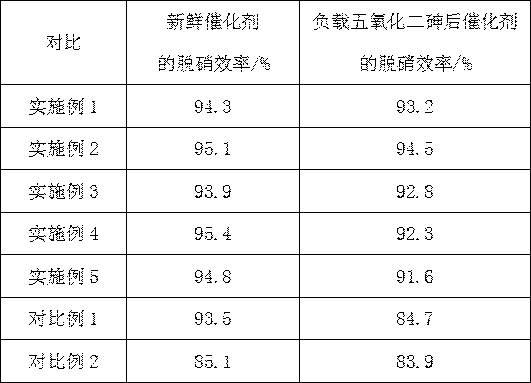

Examples

Embodiment 1

[0023] 1) 35 parts by mass of 5% Ce-ZSM-5 zeolite molecular sieve, containing 5% SO 4 2- 65 parts by mass of titanium dioxide and 10 parts by mass of zirconium-molybdenum composite oxide prepared by high-energy ball milling (where the content of zirconia is 0 parts by mass and the content of molybdenum oxide is 10 parts by mass), 2 parts by mass of hydroxypropyl methylcellulose, Put 1 mass part of basalt fiber, 0.25 mass part of cetyltrimethylammonium bromide, and 0.25 mass part of sucrose into a mixer and stir for 30 minutes, then add 2 mass parts of silica sol and 249 mass parts of deionized water and knead for 60 minutes to obtain plastic clay material, and then put the mud into the mud training machine and practice the mud repeatedly for 3 times;

[0024] 2) Put the mud obtained in step 1) stale for 12 hours, then pass through a 60-mesh filter in a pre-extruder with a vacuum degree of 0.09MPa, and extrude into strips of mud;

[0025] 3) Extrude the sludge obtained in ste...

Embodiment 2

[0029] 1) 45 parts by mass of 15%-β molecular sieve containing 8% SO 4 2- 55 parts by mass of titanium dioxide and 20 parts by mass of zirconium-molybdenum composite oxide prepared by high-energy ball milling (including 5 parts by mass of zirconia and 15 parts by mass of molybdenum oxide), 4 parts by mass of hydroxypropyl methylcellulose, Put 3 parts by mass of basalt fiber, 1.2 parts by mass of cetyltrimethylammonium bromide, and 0.3 parts by mass of sucrose into a mixer and stir for 30 minutes, then add 5 parts by mass of silica sol and 300 parts by mass of deionized water and knead for 60 to 90 minutes to obtain Plastic mud, and then put the mud into the mud refining machine and practice the mud repeatedly 5 times;

[0030] 2) Put the sludge obtained in step 1) stale for 24 hours, then pass through an 80-mesh filter in a pre-extruder with a vacuum degree of 0.098 MPa, and extrude it into strips of sludge;

[0031]3) Extrude the sludge obtained in step 2) through a die und...

Embodiment 3

[0035] 1) 40 parts by mass of 10% Ce-Y molecular sieve containing 6% SO 4 2- 60 parts by mass of titanium dioxide and 15 parts by mass of zirconium-molybdenum composite oxide prepared by high-energy ball milling (including 5 parts by mass of zirconia and 10 parts by mass of molybdenum oxide), 3 parts by mass of hydroxypropyl methylcellulose, Put 2 parts by mass of basalt fiber, 0.75 parts by mass of cetyltrimethylammonium bromide, and 0.75 parts by mass of sucrose into a mixer and stir for 45 minutes, then add 0.5 parts by mass of pine tar, 4 parts by mass of silica sol, and 270 parts by mass of deionized water Knead for 80 minutes to obtain plastic mud, then put the mud into the mud trainer and practice the mud repeatedly 4 times;

[0036] 2) Put the sludge obtained in step 1) stale for 18 hours, then pass through a 70-mesh filter in a pre-extruder with a vacuum of 0.095 MPa, and extrude it into a strip of sludge;

[0037] 3) Extrude the sludge obtained in step 2) through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com