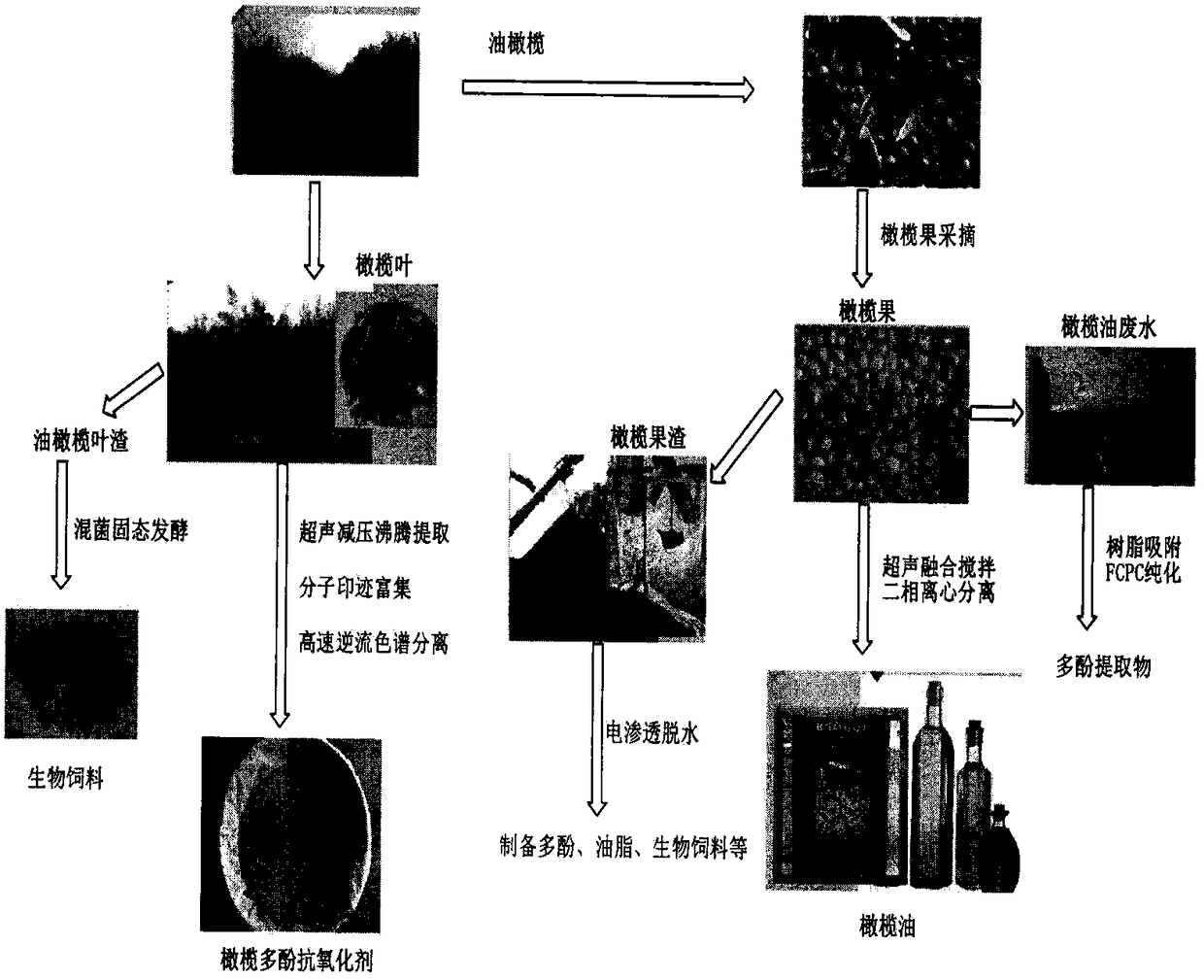

High-quality olive oil processing and waste pomace recycling method

A kind of olive oil, high-quality technology, applied in the direction of chemical instruments and methods, applications, fat oil/fat production, etc., can solve the problems of low fruiting rate, large planting area, and few suitable growing areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

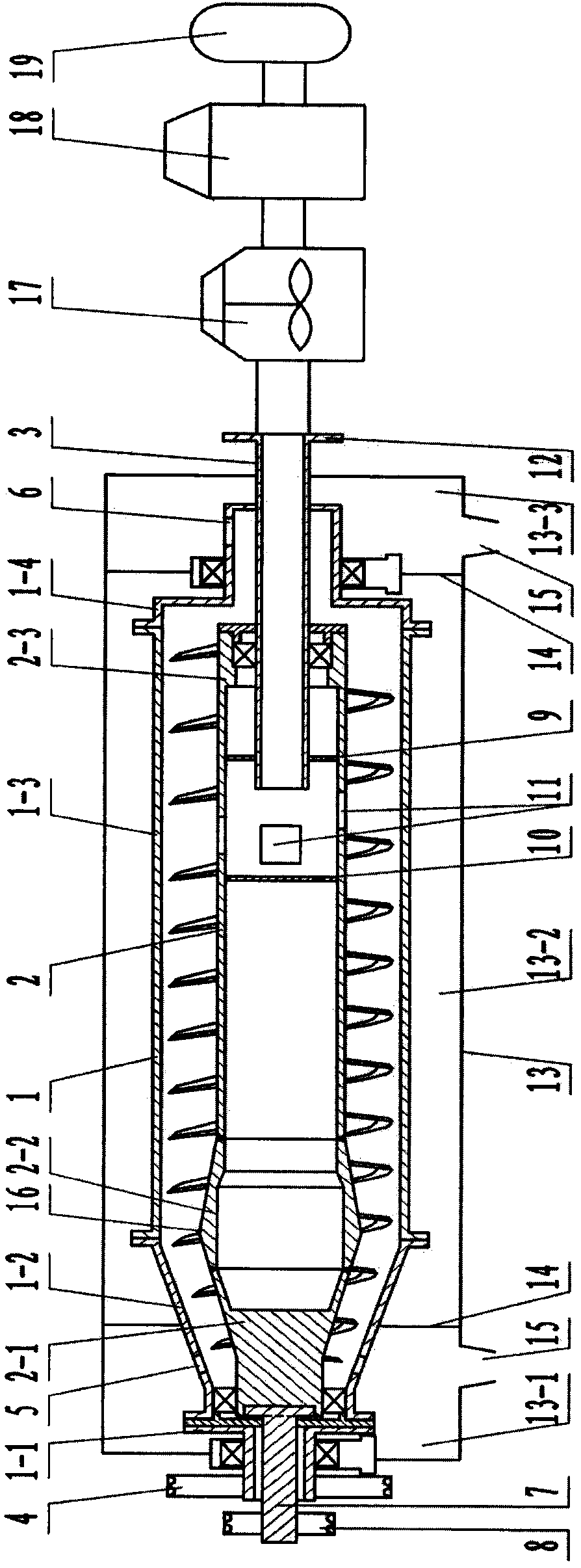

[0088] Example 1: Design of Horizontal Ultrasonic Assisted Spiral Centrifuge

[0089] The present invention provides a horizontal ultrasonic-assisted spiral centrifuge to solve the above-mentioned problems in the prior art. In order to make the design more obvious and easy to understand, the following will be further described in detail in conjunction with the accompanying drawings and specific implementation methods.

[0090] attached figure 2 Shown: This embodiment provides a novel horizontal ultrasonic-assisted two-phase spiral centrifuge, including an ultrasonic wall-breaking fuser, a base, a drum, a screw pusher and a central feeding shaft.

[0091] The ultrasonic wall breaking fusion device includes a material feed pump, an ultrasonic wall breaking device and a mechanical fusion device; ultrasonic waves refer to mechanical waves with a frequency of about 20 kHz to 50 MHz, and two ultrasonic vibrators are arranged in parallel at the bottom of the wall breaking device. T...

Embodiment 2

[0098] Embodiment 2: rich in polyphenol olive oil processing method

[0099] Design a novel horizontal ultrasonic-assisted spiral centrifuge through Example 1, store fresh olives for no more than 2 days, and obtain fruit pulp through cleaning, debranching and crushing with a hammer crusher, and the beating frequency is 2000~3000r / Min, preferably 2500r / Min, the filter screen of the crusher is 0.5-0.8cm, preferably 0.6cm, and the water content of the fruit pulp is kept at 55-70%. Preferably 2-5 MHz, the ultrasonic power is 1-5kW, choose 3kw, the ultrasonic time is 5-30min, preferably 15-20min, the belt conveying speed of fruit pulp in the ultrasonic wall breaker is 0.01-0.5m / min, preferably 0.05- 0.2m / min fruit pulp transportation accumulation 0.1 ~ 4cm. The fresh olive pulp after ultrasound is continuously conveyed by the screw, the belt conveying speed is 0.10m / min, the pulp is transported and piled up to 1cm, it is mechanically stirred, the stirring speed is 20r / min, and th...

Embodiment 3

[0101] Embodiment 3: Preparation of biological fertilizer by electroosmosis treatment pomace

[0102] In the experiment of electroosmotic dehydration of olive oil waste, olive oil waste was placed between two circular electrodes, the upper titanium plate anode was connected to positive electricity, and the lower stainless steel cathode was connected to negative electricity. A 400-mesh nylon filter cloth is placed on the upper part of the cathode to intercept fine particles in the waste. Mechanical pressure during spin is provided by adding French weights above the piston. Waste pomace is dehydrated by electroosmosis. The dehydration conditions are mechanical pressure of 50-100kPa, voltage gradient of 60-100V / cm, cake thickness of 1cm, dehydration time of 5-20min, and average dehydration power consumption of 0.1-0.3kwh / kg.

[0103] In order to investigate the influence of different mechanical pressures on the electroosmotic dehydration of olive oil waste, this embodiment adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| residual oil rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com