Multifunctional ultra-thin steel structure fireproof anticorrosive waterborne coating and construction method thereof

A technology of water-based coatings and steel structures, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problem that steel structures cannot withstand the catastrophic consequences of fire and collapse, and achieve the effect of excellent bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

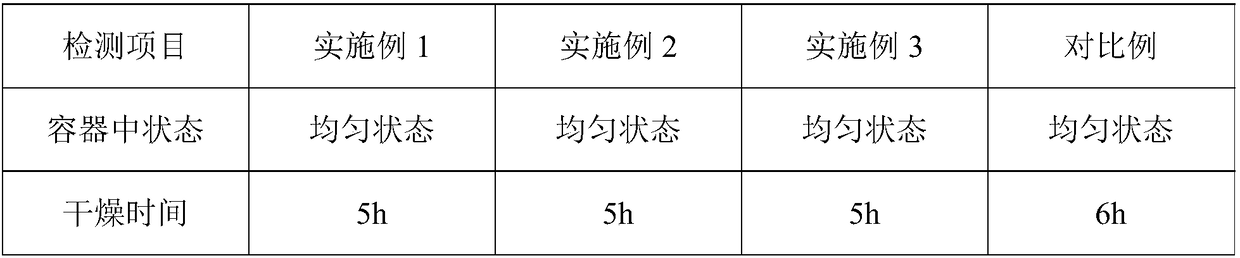

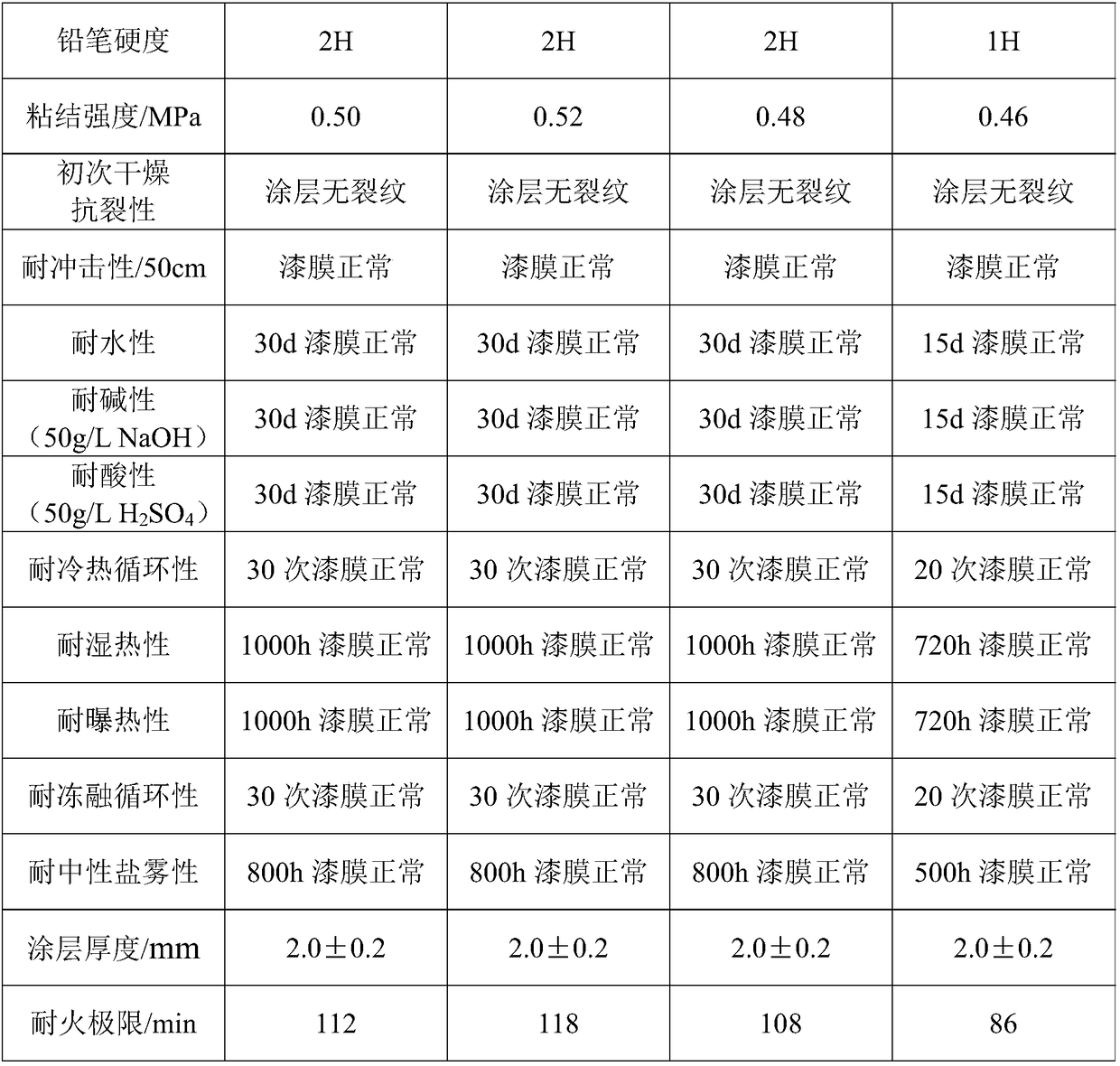

Examples

Embodiment 1

[0038] A multifunctional ultra-thin steel structure fireproof and anticorrosion water-based coating, which consists of: 30.0 parts of polyether ether ketone modified acrylic water-based resin A, 0.2 parts of wetting agent, 1.5 parts of dispersing agent, ammonium polyphosphate 24.5 parts, 8.5 parts of melamine, 8.0 parts of pentaerythritol, 3.0 parts of titanium dioxide, 4.0 parts of aluminum tripolyphosphate, 3.0 parts of kaolin, 1.0 parts of anti-flash rust agent, 0.1 parts of defoaming agent, 0.2 parts of pH regulator, 2.0 parts of propylene glycol methyl ether parts, 0.5 parts of anti-settling agent, and 13.5 parts of deionized water.

[0039] Wherein, the polyetheretherketone-modified acrylic water-based resin A is described in Example 4 of the invention patent "An ATRP-synthesized polyetheretherketone-modified acrylic water-based resin".

Embodiment 2

[0041] A multifunctional ultra-thin steel structure fireproof and anticorrosion water-based coating, which consists of: 32.0 parts of polyether ether ketone modified acrylic water-based resin B, 0.2 parts of wetting agent, 2.0 parts of dispersant, 25.0 parts of ammonium polyphosphate 9.0 parts of dicyandiamide, 7.5 parts of dipentaerythritol, 3.0 parts of titanium dioxide, 3.0 parts of aluminum tripolyphosphate, 3.0 parts of talc powder, 2.0 parts of zinc phosphate, 0.1 parts of defoamer, 0.2 parts of pH regulator, propylene glycol methyl ether 2.0 parts, 0.5 parts of anti-settling agent, 10.5 parts of deionized water.

[0042] Wherein, the polyetheretherketone-modified acrylic water-based resin B is described in Example 5 of the invention patent "An ATRP-synthesized polyetheretherketone-modified acrylic water-based resin".

Embodiment 3

[0044] A multifunctional ultra-thin steel structure fireproof and anticorrosion water-based coating, which consists of: 28.0 parts of polyether ether ketone modified acrylic water-based resin C, 0.2 parts of wetting agent, 1.6 parts of dispersant, 25.0 parts of ammonium polyphosphate 8.0 parts of melamine, 8.0 parts of sucrose, 3.0 parts of titanium dioxide, 4.0 parts of aluminum tripolyphosphate, 3.0 parts of talcum powder, 2.0 parts of zinc oxide, 0.1 parts of defoamer, 0.2 parts of pH regulator, 2.0 parts of propylene glycol methyl ether, 0.5 parts of anti-settling agent, 14.4 parts of deionized water.

[0045] Wherein, the polyetheretherketone-modified acrylic water-based resin C is described in Example 6 of the invention patent "An ATRP-synthesized polyetheretherketone-modified acrylic water-based resin".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com