Biomass energy particle with high burning rate and preparation technology thereof

A technology of biomass energy and preparation technology, applied in the field of biomass energy particles and its preparation, can solve the problems of insufficient explosive power of biomass fuel, slow combustion speed, and large environmental pollution, and achieve stable combustion, complete combustion, and no environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

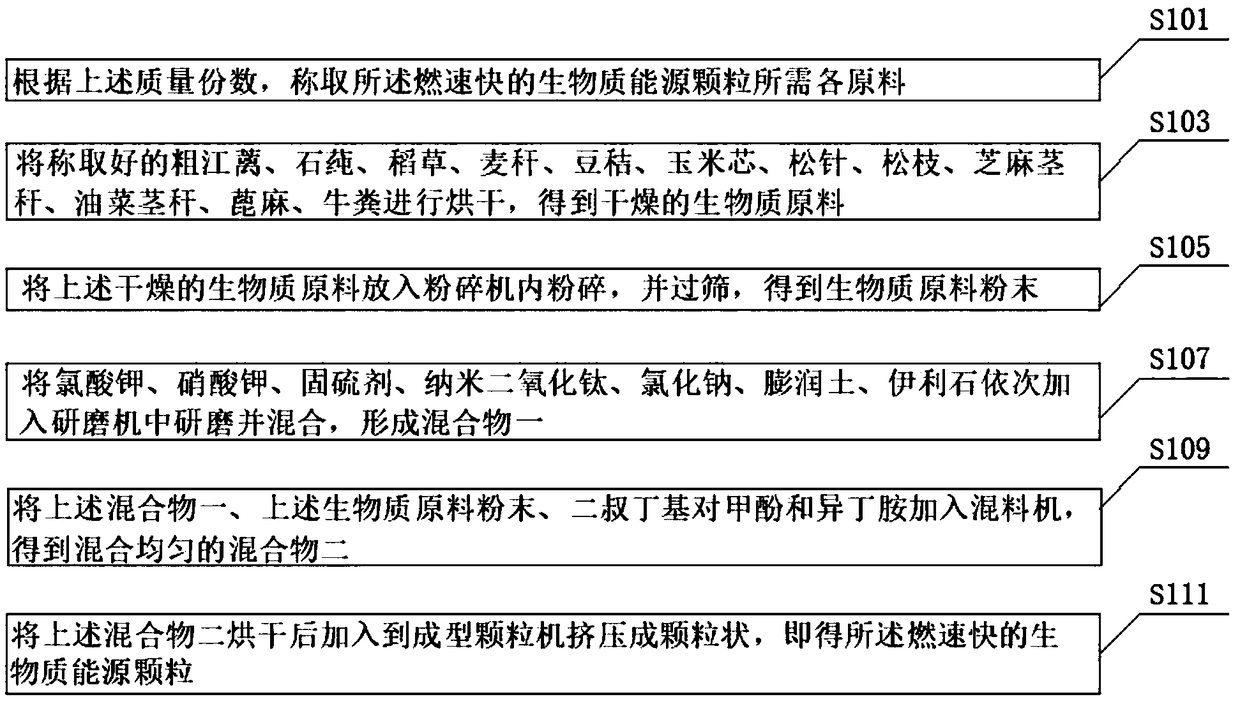

Method used

Image

Examples

Embodiment 1

[0061] A biomass energy particle with a fast burning rate, the biomass energy particle with a fast burning rate is made of the following raw materials in parts by mass:

[0062] 30kg of large seaweed, 60kg of straw, 15kg of corn cob, 8kg of pine needle, 10kg of pine branch, 10kg of sesame stalk, 13kg of rape stalk, 10kg of castor plant, 12kg of cow dung, 6kg of combustion aid, 4kg of sulfur-fixing agent, 6kg of stabilizer, nano titanium dioxide 2kg, sodium chloride 3kg, bentonite 1kg, illite 2kg.

[0063] Wherein, the straw includes the following raw material components: 15kg of rice straw, 23kg of wheat straw and 22kg of bean straw.

[0064] The combustion aid comprises the following raw material components: 4 kg of potassium chlorate and 2 kg of potassium nitrate.

[0065] The large seaweed comprises the following raw material components: 14 kg of Gracilaria undulata and 16 kg of Ulva.

[0066] The stabilizer includes the following raw material components: 4 kg of di-tert-...

Embodiment 2

[0075] A biomass energy particle with a fast burning rate, the biomass energy particle with a fast burning rate is made of the following raw materials in parts by mass:

[0076] Large seaweed 35kg, straw 70kg, corn cob 17kg, pine needle 10kg, pine branch 13kg, sesame stalk 14kg, rape stalk 14kg, castor plant 12kg, cow dung 14kg, combustion enhancer 9kg, sulfur fixing agent 7kg, stabilizer 10kg, nano titanium dioxide 4kg, sodium chloride 5kg, bentonite 2kg, illite 3kg.

[0077] Wherein, the straw includes the following raw material components: 17kg of rice straw, 27kg of wheat straw and 26kg of bean straw.

[0078] The combustion aid comprises the following raw material components: 6 kg of potassium chlorate and 3 kg of potassium nitrate.

[0079] The large seaweed comprises the following raw material components: 16 kg of Gracilaria undulata and 19 kg of Ulva.

[0080] The stabilizer includes the following raw material components: 6 kg of di-tert-butyl-p-cresol and 4 kg of is...

Embodiment 3

[0089] A biomass energy particle with a fast burning rate, the biomass energy particle with a fast burning rate is made of the following raw materials in parts by mass:

[0090] 40kg of large seaweed, 80kg of straw, 19kg of corn cob, 12kg of pine needle, 16kg of pine branch, 18kg of sesame stalk, 15kg of rape stalk, 14kg of castor, 16kg of cow dung, 12kg of combustion enhancer, 10kg of sulfur fixative, 14kg of stabilizer, nano titanium dioxide 6kg, sodium chloride 7kg, bentonite 3kg, illite 4kg.

[0091] Wherein, the straw includes the following raw material components: 19kg of rice straw, 31kg of wheat straw and 30kg of bean straw.

[0092] The combustion aid comprises the following raw material components: 8 kg of potassium chlorate and 4 kg of potassium nitrate.

[0093] The large seaweed comprises the following raw material components: 18 kg of Gracilaria spp. and 22 kg of Ulva.

[0094] The stabilizer includes the following raw material components: 8 kg of di-tert-butyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com