Biomass granular fuel and preparation method thereof

A technology of biomass pellets and fuels, which is applied in the direction of biofuels, waste fuels, fuels, etc., and can solve problems such as environmental pollution and easy poplar dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

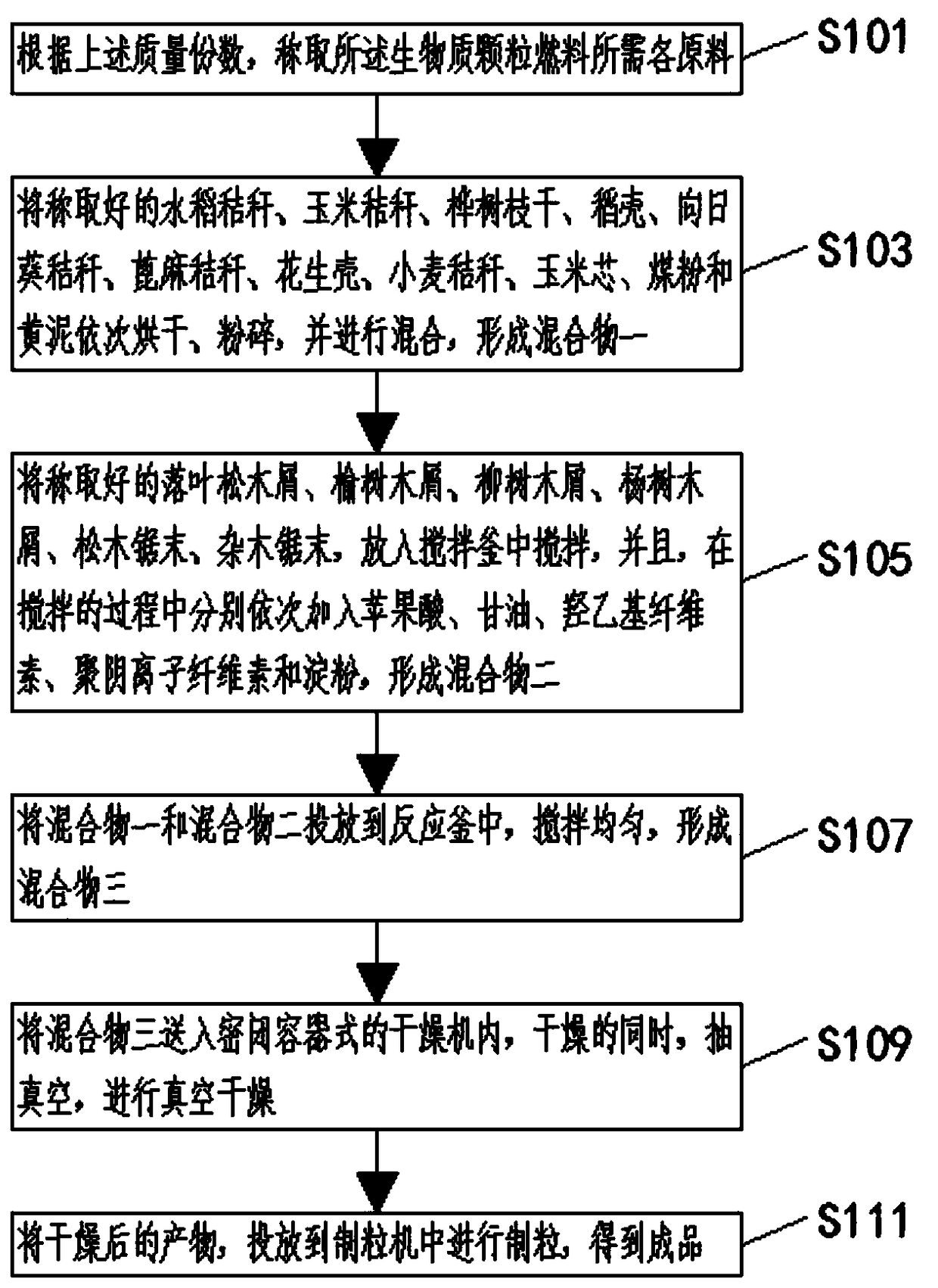

Method used

Image

Examples

Embodiment 1

[0062] A kind of biomass particle fuel, this biomass particle fuel is made of the following raw materials of mass fraction:

[0063] 20g of rice straw, 40g of corn straw, 20g of birch branches, 20g of rice husk, 20g of sunflower straw, 10g of castor plant straw, 15g of peanut shell, 20g of wheat straw, 9g of corn cob, 10g of coal powder, 7g of yellow mud, 45g of sawdust composition , 30 g of sawdust composition, 12 g of biomass polyester, and 13 g of adhesive.

[0064] Wherein, the wood chip composition includes the following raw material components: 15g of larch wood chips, 10g of elm wood chips, 10g of willow wood chips, and 10g of poplar wood chips.

[0065] The sawdust composition includes the following raw material components: 10g of pine sawdust and 20g of miscellaneous wood sawdust.

[0066] The biomass polyester includes the following raw material components: 2 g of malic acid and 10 g of glycerin are mixed.

[0067] The binder includes the following raw material com...

Embodiment 2

[0076] A kind of biomass particle fuel, this biomass particle fuel is made of the following raw materials of mass fraction:

[0077] 30g of rice straw, 45g of corn straw, 25g of birch branches, 25g of rice husk, 25g of sunflower straw, 15g of castor plant straw, 19g of peanut shell, 25g of wheat straw, 11g of corncob, 15g of coal powder, 11g of yellow mud, 55g of sawdust composition , 50 g of sawdust composition, 19 g of biomass polyester, and 18 g of adhesive.

[0078] Wherein, the wood chip composition includes the following raw material components: 16g of larch wood chips, 13g of elm wood chips, 13g of willow wood chips, and 13g of poplar wood chips.

[0079] The sawdust composition includes the following raw material components: 20g of pine sawdust and 30g of miscellaneous wood sawdust.

[0080] The biomass polyester includes the following raw material components: 4 g of malic acid and 15 g of glycerin are mixed.

[0081] The binder includes the following raw material co...

Embodiment 3

[0090] A kind of biomass particle fuel, this biomass particle fuel is made of the following raw materials of mass fraction:

[0091] 40g rice straw, 50g corn straw, 30g birch branch, 30g rice husk, 30g sunflower straw, 20g castor plant straw, 23g peanut shell, 30g wheat straw, 30g corn cob, 20g coal powder, 15g yellow mud, 65g sawdust composition , 70g of sawdust composition, 25g of biomass polyester, and 23g of adhesive.

[0092] Wherein, the wood chip composition includes the following raw material components: 17g of larch wood chips, 16g of elm wood chips, 16g of willow wood chips, and 16g of poplar wood chips.

[0093] The sawdust composition includes the following raw material components: 30g of pine sawdust and 40g of miscellaneous wood sawdust.

[0094] The biomass polyester includes the following raw material components: 5 g of malic acid and 20 g of glycerin are mixed.

[0095] The binder includes the following raw material components: 3 g of hydroxyethyl cellulose,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com