A method for sodium oxalate modified zero-valent iron to remove hexavalent chromium in water

A technology of zero-valent iron and sodium oxalate, which is applied to chemical instruments and methods, water pollutants, mining wastewater treatment, etc., can solve the problems of low activity of hexavalent chromium and poor reducing ability, and achieve high content, simple structure, and easy treatment. The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Effect of sodium oxalate modified zero-valent iron in controlling hexavalent chromium in polluted water

[0028] Weigh 4g of zero-valent iron, soak it in 0.2mol / L sodium oxalate solution for 1h, filter and wash, and dry the treated zero-valent iron under the protection of inert gas.

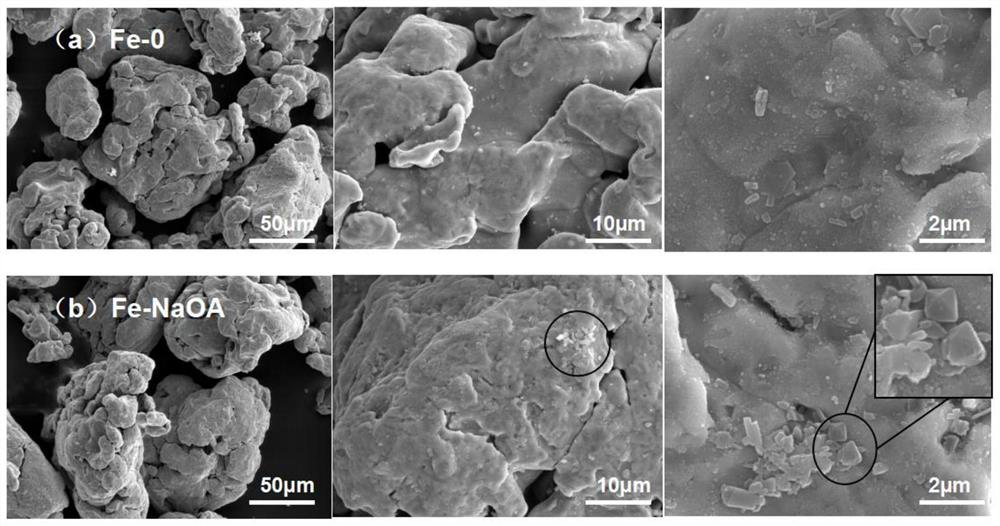

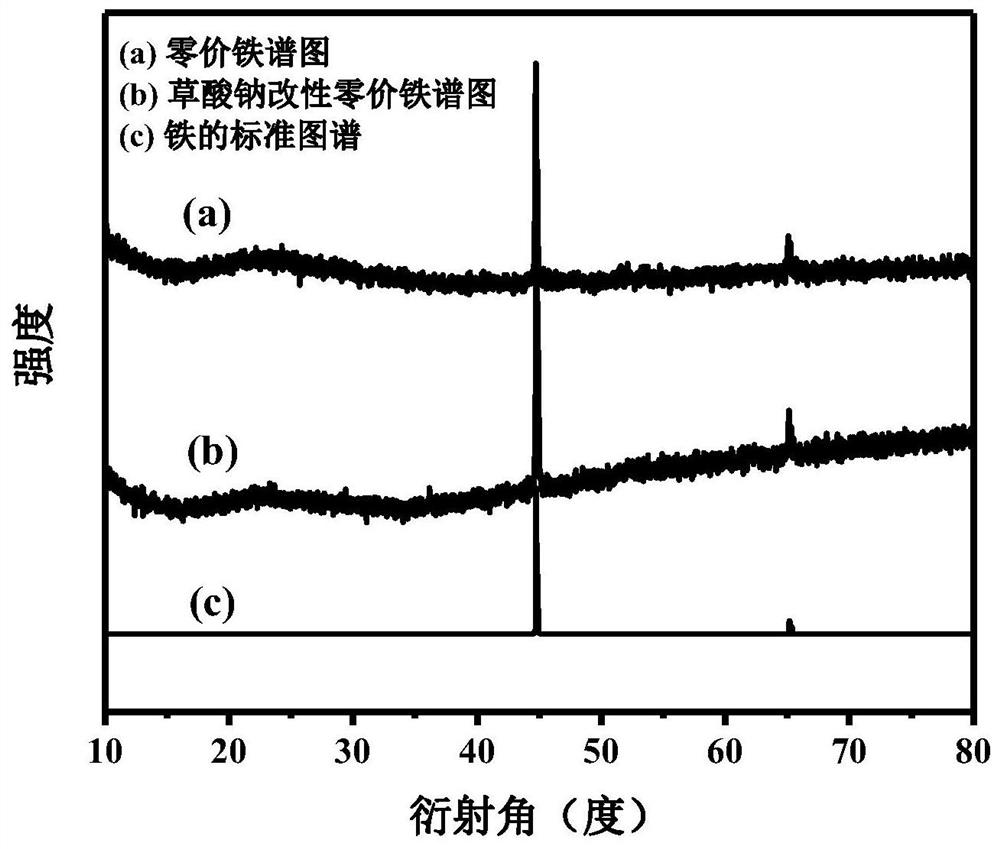

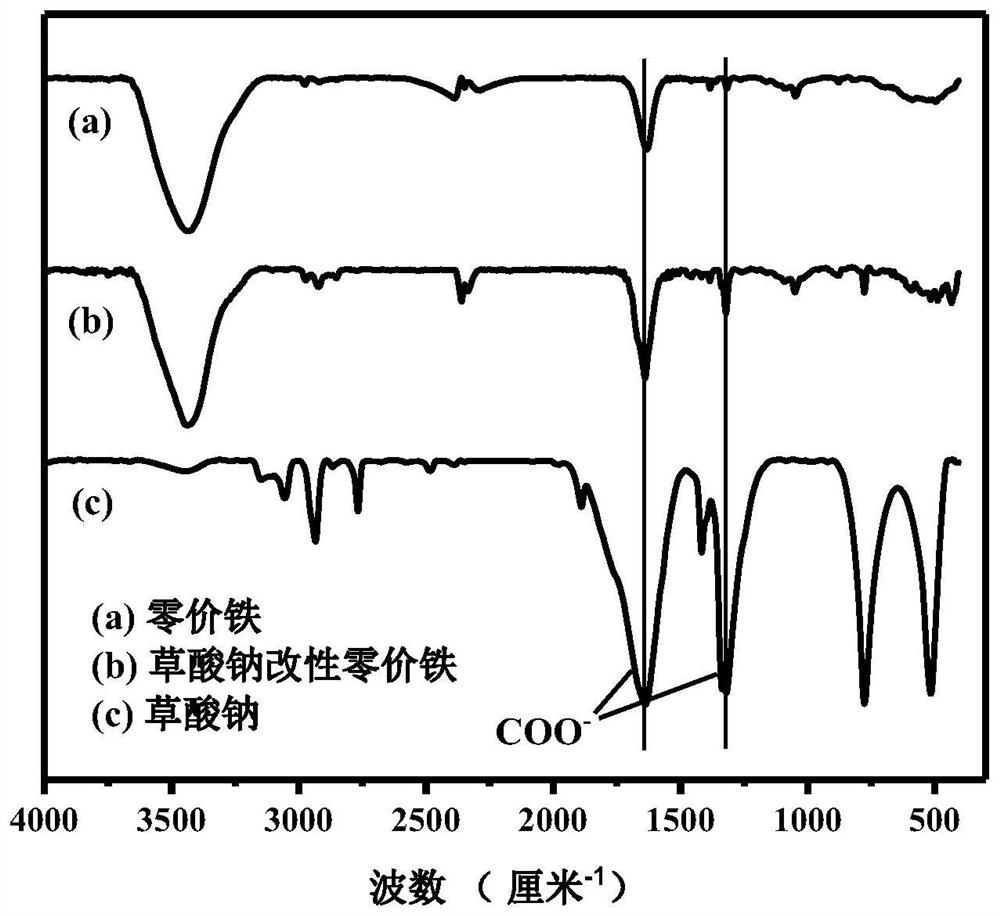

[0029] The zero-valent iron used in the inventive method and the zero-valent iron modified by sodium oxalate (the zero-valent iron used and the modified zero-valent iron by sodium oxalate are consistent with example 2), the result of the sample scanning electron microscope (SEM) shows (see figure 1 ): Compared with untreated zero-valent iron, the surface shell of zero-valent iron modified by sodium oxalate cracked and produced some fine crystal particles, which indicated that high concentration of sodium oxalate interacted with the surface shell of zero-valent iron. The reaction may be due to the replacement of the hydroxyl group on the surface of the zero-valent iron by oxala...

Embodiment 2

[0031] Example 2 The effect of different concentrations of sodium oxalate modified zero-valent iron in the treatment of hexavalent chromium in polluted water

[0032]Weigh 4g of zero-valent iron, soak it with 0mol / L, 0.10mol / L, 0.15mol / L, 0.20mol / L, and 0.25mol / L sodium oxalate solution for 2h, filter and wash, and the zero-valent iron after treatment is in the Dry under inert gas protection. Take 50mL of hexavalent chromium aqueous solution with a concentration of 2mg / L as the simulated wastewater, add 0.10g of zero-valent iron modified by sodium oxalate to it, put it in a shaker at a constant temperature of 25°C and rotate at 200rpm / min, take samples regularly, and use spectrophotometry Measure the concentration of hexavalent chromium. At the same time, untreated zero-valent iron was used as a control test, and the results are shown in Figure 6 . Figure 6 As shown, after reacting for 3 hours, the removal rate of hexavalent chromium in the modified zero-valent iron syste...

Embodiment 3

[0033] Example 3 Different treatment time sodium oxalate modified zero-valent iron treatment effect of hexavalent chromium in polluted water

[0034] Weigh 4g of zero-valent iron, soak in 0.20mol / L sodium oxalate solution for 0h, 0.5h, 1.0h, 1.5h, and 2h, filter and wash, and dry the treated zero-valent iron under the protection of inert gas. Take 50mL of hexavalent chromium aqueous solution with a concentration of 2mg / L as the simulated wastewater, add 0.25g of zero-valent iron modified by sodium oxalate into it, put it in a shaker at a constant temperature of 25°C and rotate at 200rpm / min, take samples regularly, and use spectrophotometry Measure the concentration of hexavalent chromium. At the same time, untreated zero-valent iron was used as a control test, and the results are shown in Figure 7 . Figure 7 As shown, after 3 hours of reaction, the removal rate of hexavalent chromium in the modified zero-valent iron system is higher than that in the unmodified system, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com