A kind of silicon-containing aryne polymer and preparation method thereof

A technology of polymer and silicon aryne, which is applied in the field of silicon-containing aryne polymer and its preparation, can solve the problems of cumbersome polymer process and increased cost, and achieve the effects of good solubility, mild reaction conditions and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation method of the silicon-containing aryne polymer of the present embodiment, the specific reaction formula is as follows:

[0063]

[0064] The silane monomer is Alkyne monomers are

[0065] The preparation method of above-mentioned silicon-containing aryne polymer, comprises the steps:

[0066] (1) Add 440mg (5mmol) of silane monomer, 630mg (5mmol) of acetylenic monomer, 20mg (0.5mmol) of sodium hydroxide, and 5mL of ethylene glycol dimethyl ether into the polymerization tube. After reacting at ℃ for 12h, the reaction was stopped, cooled to room temperature, and an intermediate product was obtained;

[0067] (2) Add the intermediate product dropwise to n-hexane while stirring, a large amount of solids are precipitated, after stirring for 15 minutes, suction filtration, the obtained solids are placed in a vacuum oven and dried for 6 hours to obtain the silicon-containing aryne polymer P1, produced The rate is 67.9%.

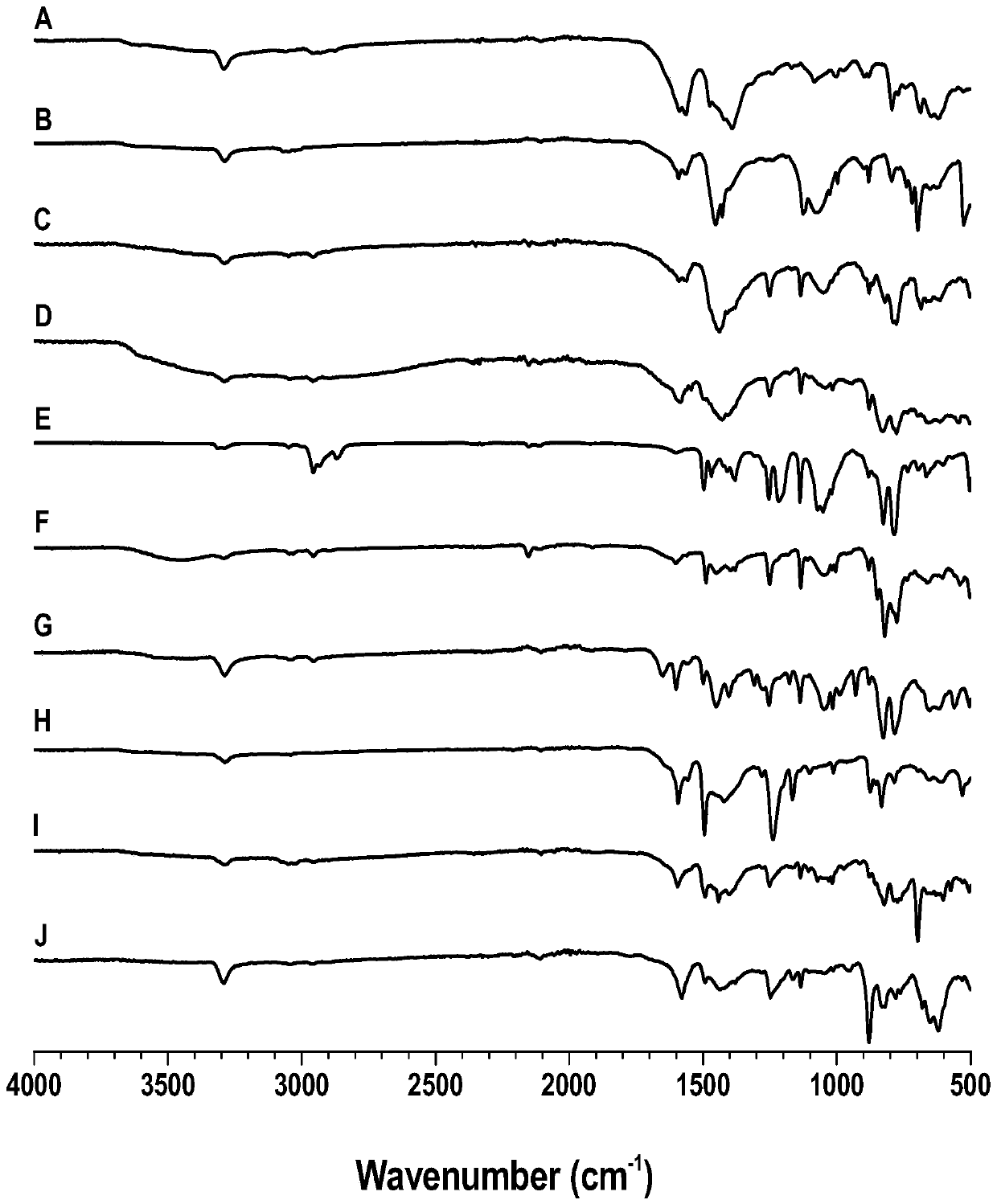

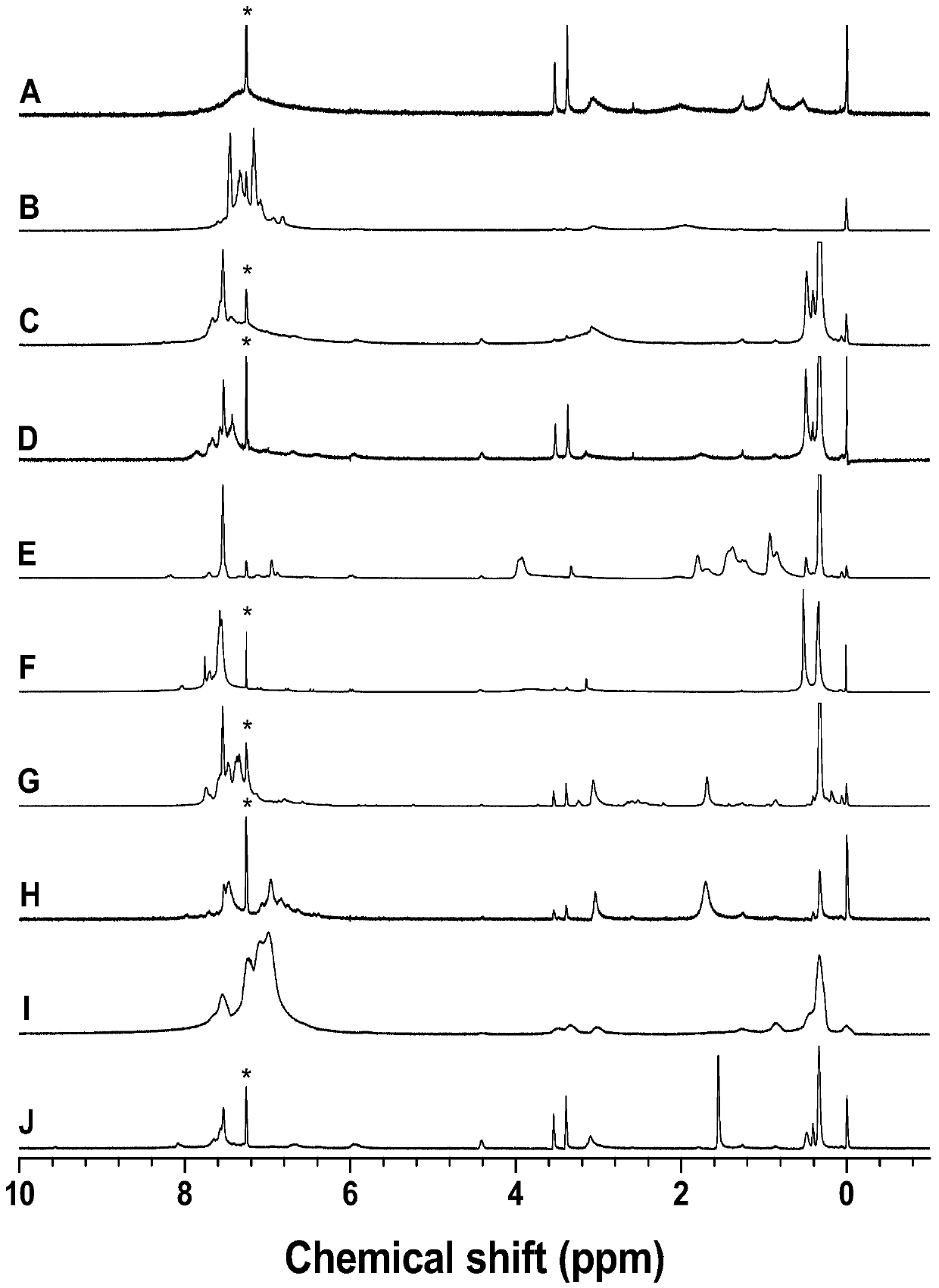

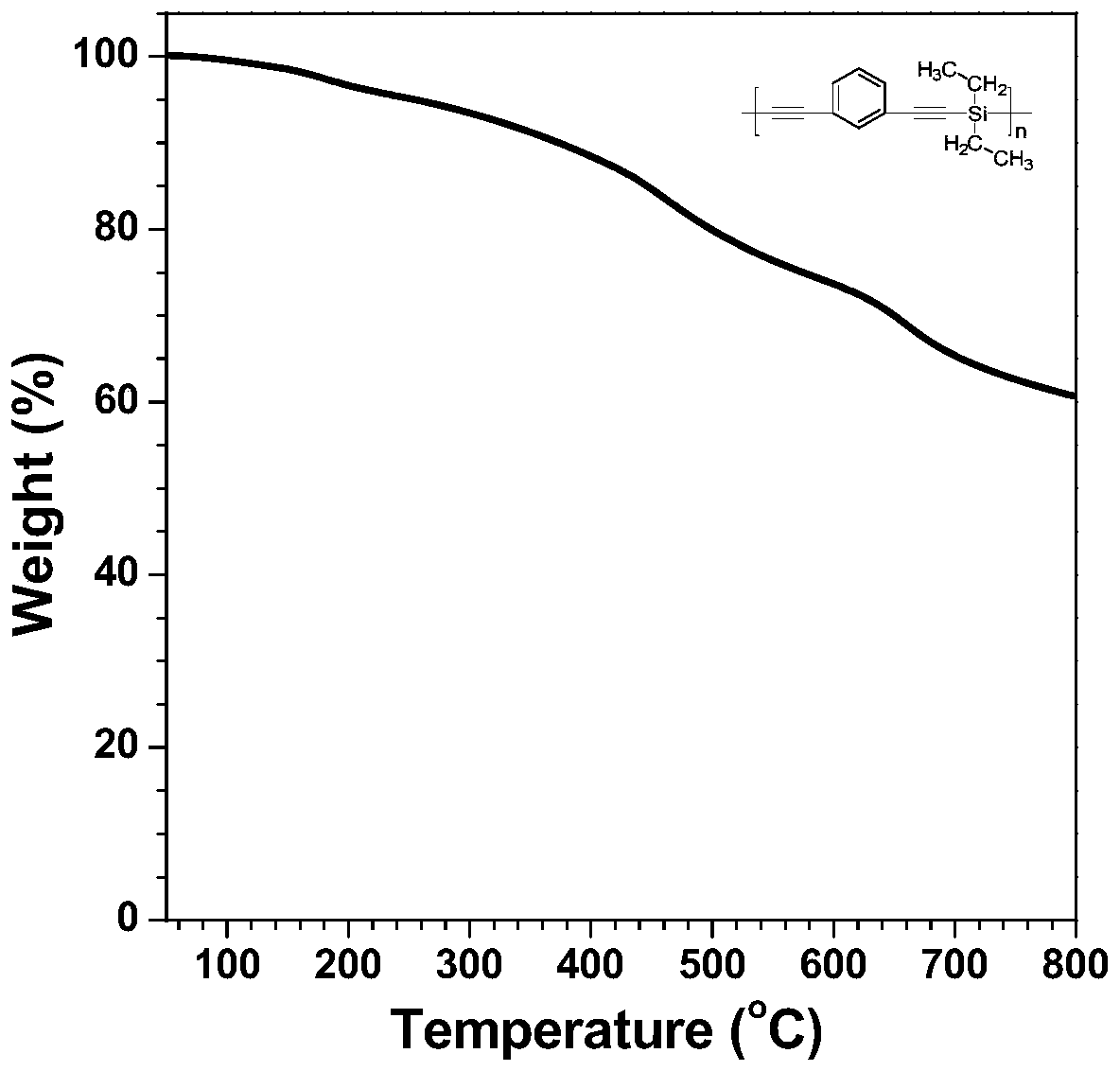

[0068] The silicon-containing...

Embodiment 2

[0071] The preparation method of the silicon-containing aryne polymer of the present embodiment, the specific reaction formula is as follows:

[0072]

[0073] The silane monomer is Alkyne monomers are

[0074] The preparation method of above-mentioned silicon-containing aryne polymer, comprises the steps:

[0075] (1) Add 920mg (5mmol) of silane monomer, 630mg (5mmol) of acetylenic monomer, 20mg (0.5mmol) of sodium hydroxide, and 5mL of ethylene glycol dimethyl ether into the polymerization tube. After reacting at ℃ for 12h, the reaction was stopped, cooled to room temperature, and an intermediate product was obtained;

[0076] (2) Add the intermediate product dropwise to n-hexane while stirring, and a large amount of solids are precipitated. After stirring for 15 minutes, suction filtration is performed, and the obtained solids are dried in a vacuum oven for 6 hours to obtain the silicon-containing aryne polymer P2. The rate is 73.2%.

[0077] The silicon-containin...

Embodiment 3

[0080] The preparation method of the silicon-containing aryne polymer of the present embodiment, the specific reaction formula is as follows:

[0081]

[0082] The silane monomer is Alkyne monomers are

[0083] The preparation method of above-mentioned silicon-containing aryne polymer, comprises the steps:

[0084] (1) Add 970mg (5mmol) of silane monomer, 630mg (5mmol) of acetylenic monomer, 20mg (0.5mmol) of sodium hydroxide, and 5mL of ethylene glycol dimethyl ether into the polymerization tube. After reacting at ℃ for 12h, the reaction was stopped, cooled to room temperature, and an intermediate product was obtained;

[0085] (2) Add the intermediate product dropwise to n-hexane while stirring, and a large amount of solids precipitate out. After stirring for 15 minutes, filter with suction, and place the obtained solids in a vacuum oven to dry for 6 hours to obtain the silicon-containing aryne polymer P3. The rate is 52.5%.

[0086] The silicon-containing aryne po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com