Oleophobic coating material, oil-water separation functional material, preparation method thereof and use thereof

A coating material and oil-water separation technology, applied in separation methods, coatings, liquid separation, etc., can solve the problems of loss of wetting properties on the membrane surface, high cost, and difficulty in large-scale preparation, and achieve excellent underwater oleophobic properties, Suitable for industrial production, good anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Specifically, the preparation method of the present invention comprises:

[0042] A solution containing more than one first ionic compound and a solution containing more than one second ionic compound are alternately coated on the substrate, so that more than one first ionic compound and more than one second ionic compound A cross-linked network structure is formed through intermolecular interactions, wherein at least one first ionic compound and at least one second ionic compound have opposite charges.

[0043] Preferably, any one of the first ionic compound and the second ionic compound is an anionic compound, and the other is a cationic compound.

[0044] If the cationic compound (also referred to as a class A compound) is polyethyleneimine, chitosan and / or chitosan derivatives, polyvinylamine hydrochloride, polyimidazole ionic liquid, polyquaternium One or more in cationic compounds such as type ionic liquid, polydimethyldiallylammonium chloride, polydimethylaminoeth...

Embodiment 1

[0079] Step 1: Dissolve polydimethyldiallylammonium chloride with a molecular weight of 10,000 in pure water to form an aqueous solution with a concentration of 1 wt%, and then use 0.1M dilute hydrochloric acid solution to adjust the pH of the aqueous solution to 4 , the prepared solution is marked as component A solution;

[0080] Step 2: Dissolve commercially available ethylenediaminetetraacetic acid in pure water to prepare an aqueous solution with a concentration of 1 wt%, and then use 0.1M dilute hydrochloric acid solution to adjust the pH of the aqueous solution to 4, and the prepared solution is labeled For component B solution;

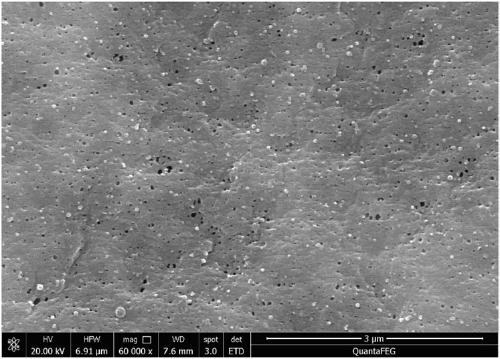

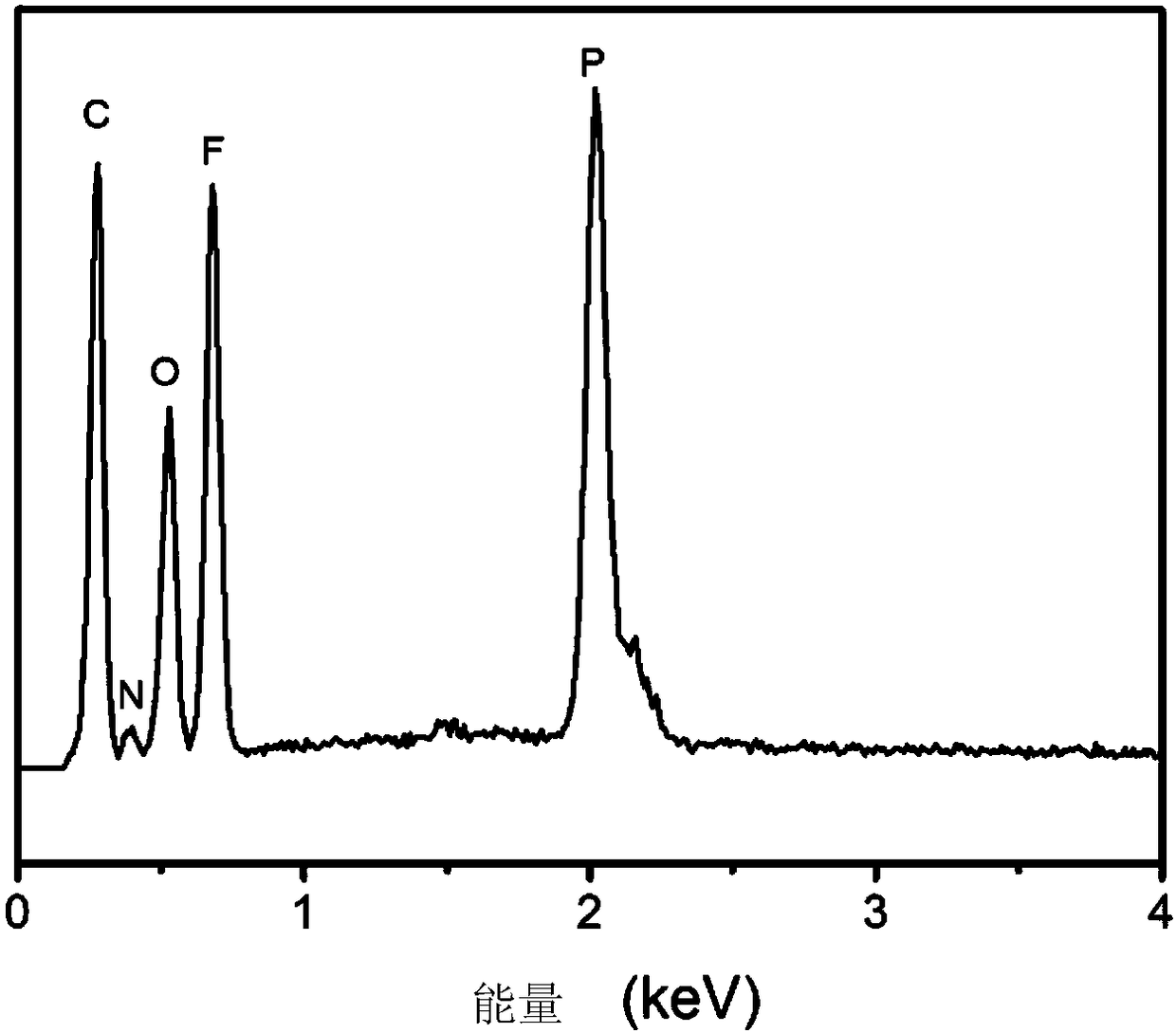

[0081] Step 3: Wash the polyvinylidene fluoride microfiltration membrane with a pore size of 0.45 μm with ethanol and pure water for 10 minutes, and then dry it for later use;

[0082] Step 4: Immerse the cleaned polyvinylidene fluoride microfiltration membrane into the component A solution, let it stand for 30 minutes, then take it out to dr...

Embodiment 2

[0087] Step 1: Dissolve polydimethyldiallylammonium chloride with a molecular weight of 100,000 in pure water to form an aqueous solution with a concentration of 5 wt%, and then adjust the pH of the aqueous solution to 4 with 0.1M dilute hydrochloric acid solution , the prepared solution is marked as component A solution;

[0088] Step 2: Dissolve commercially available ethylenediaminetetraacetic acid in pure water to prepare an aqueous solution with a concentration of 3wt%, and then use 0.1M dilute hydrochloric acid solution to adjust the pH of the aqueous solution to 4. The prepared solution is labeled For component B solution;

[0089] Step 3: ultrasonically clean the porous ceramic membrane with a pore size of 10 μm with ethanol and pure water for 10 minutes, and then dry it for later use;

[0090] Step 4: Immerse the dried porous ceramic membrane into the component A solution, let it stand for 30 minutes, then take it out to dry; then immerse the porous ceramic membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com