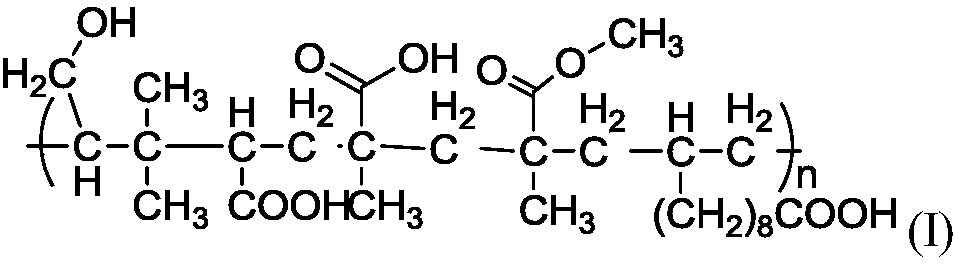

High molecular polymer, preparation method thereof and electrolyte containing same

A high-molecular polymer and electrolyte technology, applied in the field of electrolyte, can solve the problems of unrecorded solution system II thermosetting gel state electrolyte performance parameters, etc., and achieve excellent high and low temperature performance, good compatibility, flash fire The effect of high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

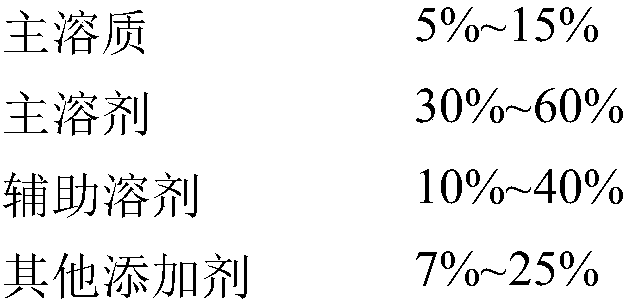

[0051] Embodiment 1 Electrolyte formula and preparation thereof

[0052]

[0053] Preparation process: Mix 52% ethylene glycol and 23% diethylene glycol evenly at room temperature, raise the temperature to 110°C, add 6% polyethylene glycol 400, 2% boric acid, 3% nano diethylene glycol at this time Silicon oxide, after 0.5 hours of heat preservation, raise the temperature to 150°C, add 8% polymer main solute, 1% polyvinyl alcohol, 1% alkyl phosphate, cool down to 130°C after heat preservation for 1 hour, open to adjust the moisture , then lower the temperature to 100°C and add 1% silicon-containing additive, 2% sodium tetraborate and 1% p-nitrobenzoic acid, and adjust the pH to 5-7 with ammonia water after cooling to normal temperature.

Embodiment 2

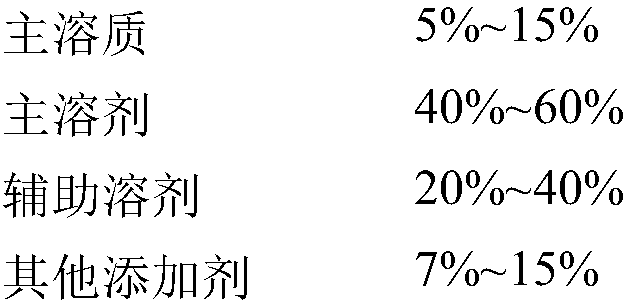

[0054] Embodiment 2 electrolyte formula and preparation thereof

[0055]

[0056] Preparation process: mix 54% ethylene glycol and 20% ethylene glycol monobutyl ether evenly at room temperature, raise the temperature to 110°C, add 6% polyethylene glycol 1000, 3% boric acid, 3% nano di Silicon oxide, after 0.5 hours of heat preservation, raise the temperature to 150°C, add 8% polymer main solute, 0.5% mannitol, 1% sorbitol, cool down to 130°C after heat preservation for 1 hour, open the mouth to adjust the water, and then Cool down to 100°C and add 2% silicon-containing additives, 1.5% sodium tetraborate and 1% p-nitrobenzoic acid, and adjust the pH to 5-7 with ammonia water after cooling down to normal temperature.

Embodiment 3

[0057] Embodiment 3 performance test

[0058] The working electrolyte parameters are shown in Table 1.

[0059] Table 1

[0060] Example

Moisture (weight%)

Conductivity (30℃, ms / cm)

pH value

Flash voltage (V)

Example 1

2.01

0.77

5.59

691

Example 2

1.98

0.79

5.57

686

[0061] The characteristics and changes of the electrolytic capacitor obtained by using the electrolyte of the embodiment of the present invention are shown in Table 2 after 3000 hours at 85°C.

[0062] Table 2

[0063]

[0064] From the change of electrolyte and product performance parameters in Table 1 and Table 2, it can be found that the flashover voltage of the electrolytic capacitor obtained by using the high molecular polymer shown in formula (I) as the electrolyte of the main solute is higher (>680V). The 650V ultra-high voltage capacitor prepared with the high molecular polymer as the main solute electrolyte has no change in appeara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com