A kind of catalytic cracking method

A catalytic cracking and catalyst technology, which is applied in the field of catalytic cracking, can solve the problems of increasing the yield of catalytic cracking butenes, such as the limitation, and achieve the effect of improving the conversion capacity of heavy oil, improving flexibility and increasing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

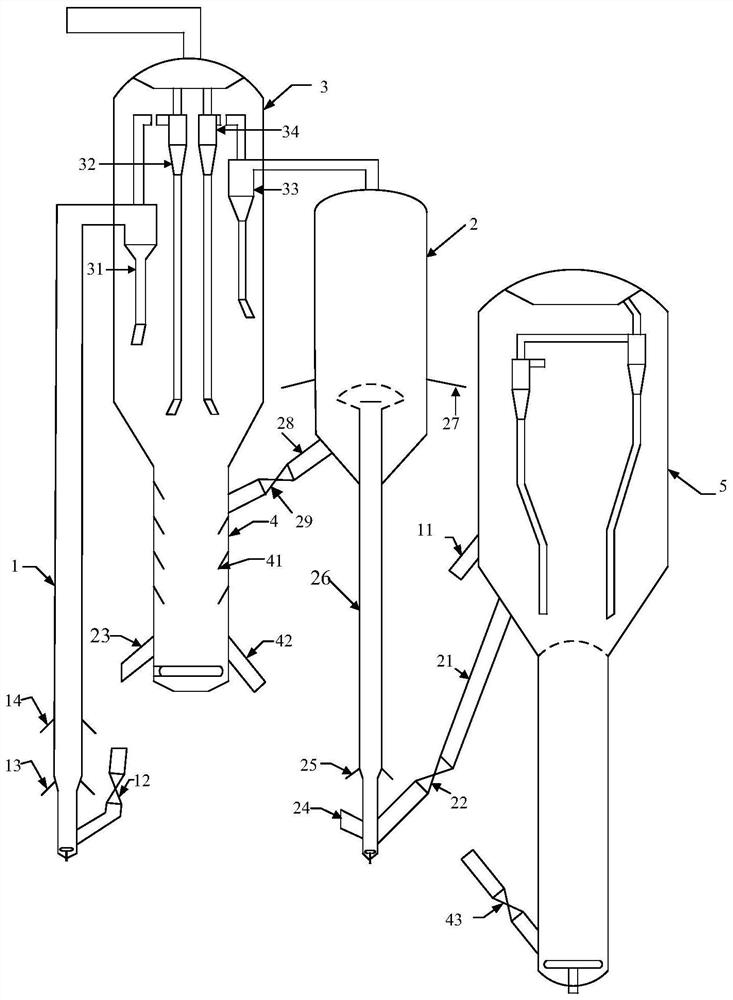

[0057] A specific embodiment, the catalytic cracking method of the present disclosure is in figure 1 Implement in the catalytic cracking unit shown, specifically, this catalytic cracking unit comprises riser reactor 1 (being the first reactor) and fluidized bed reactor 2 (being the second reactor) and settler 3, described The riser reactor 1, the fluidized bed reactor 2 and the settler 3 are arranged side by side.

[0058] In preferred cases, such as figure 1 As shown, the catalytic cracking unit implementing the method of the present disclosure includes: a riser reactor 1, a fluidized bed reactor 2, a settler 3 and a stripper 4, and the fluidized bed reactor 2 and the settler 3 pass through a or multiple channels connected. The fluidized bed reactor 2 communicates with the stripper 4 through one or more channels. Wherein, the riser reactor 1 can be at least one selected from circular tubes with equal diameters, frustum-shaped cylinders, or straight cylinders with 1-6 secti...

Embodiment 1

[0073] The cracking catalyst used in the present embodiment is: on a dry basis and based on the total weight of the catalytic cracking catalyst, the cracking catalyst used contains 10% by weight of zeolite beta, 20% by weight of ZSM-5 zeolite (the ratio of silicon to aluminum is 40 ), 10% by weight of mesoporous silica-alumina material, 35% by weight of kaolin and 25% by weight of alumina binder, wherein the beta zeolite contains 1% by weight of iron and 1.5% by weight of phosphorus in terms of elements. The catalytic cracking catalyst was aged for 10 hours at 800° C. under a 100% water vapor atmosphere, and the catalyst loading in the device (system catalyst inventory) was 60 kg.

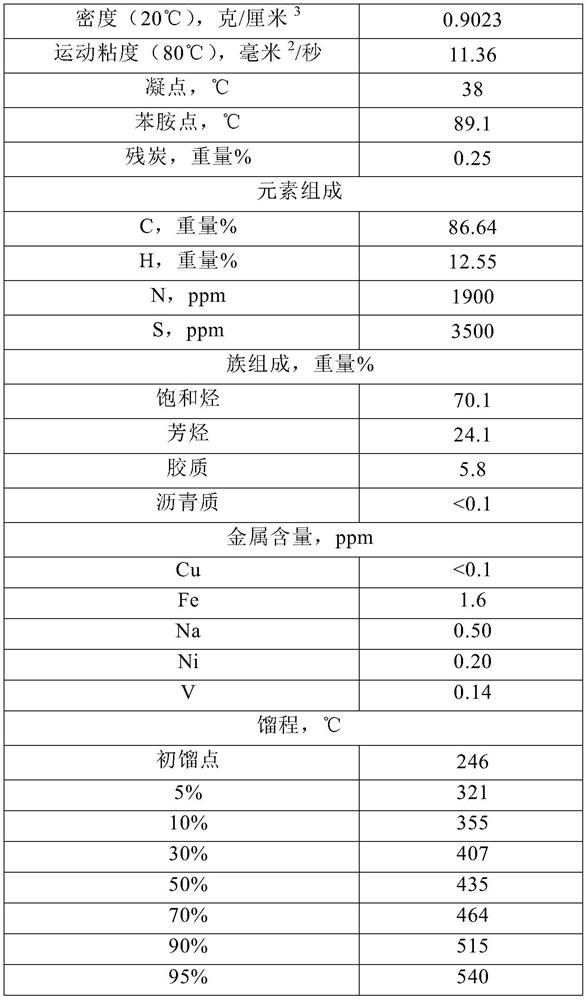

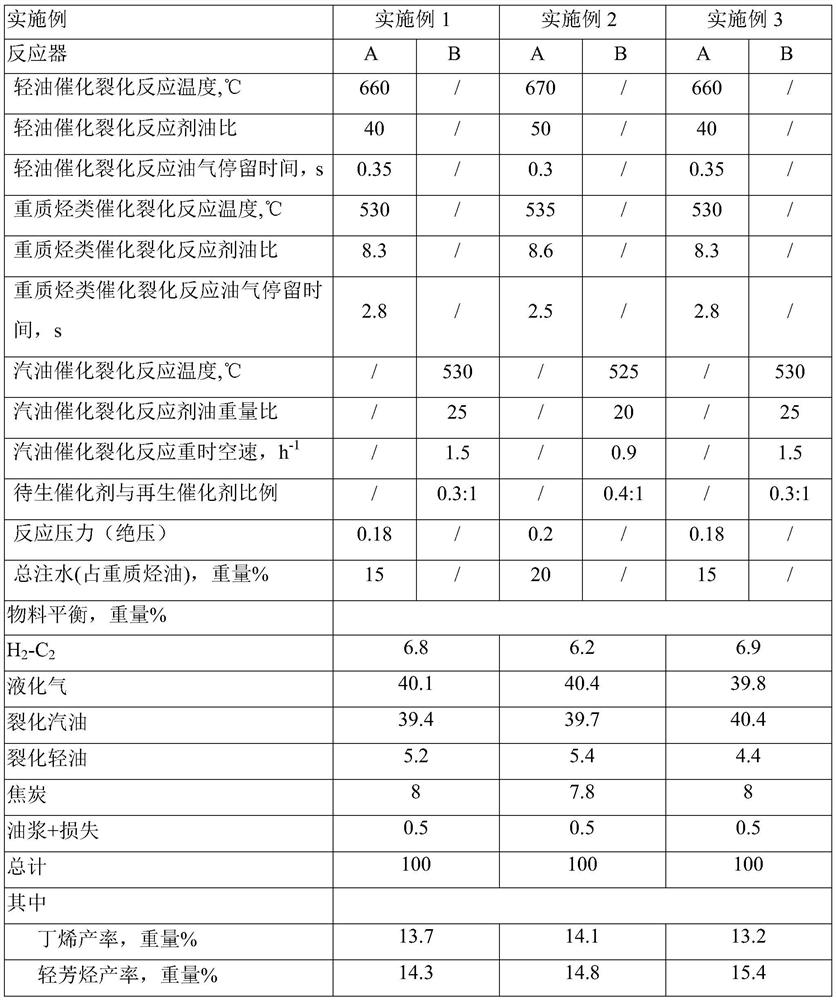

[0074] Such as figure 1 As shown, the hydrogenated cracked light oil (composition is shown in Table 1, the distillation range is 240-365 ° C) is injected into the bottom of the riser reactor 1, and is contacted with the regenerated catalyst from the regenerator to carry out the light oil catalytic ...

Embodiment 2

[0076] The flow process and the cracking catalyst used in this example are the same as in Example 1, except that the cracked gasoline (properties are shown in Table 2) is at a reaction temperature of 40°C, a reaction pressure of 0.5MPa, and a molar ratio of hydrogen to olefins of 4:1. On the hydrogenation catalyst (purchased from Sinopec Changling Catalyst Branch Company, the brand is RDD-1), through selective hydrogenation reaction, dienes and alkynes are converted into monoolefins and introduced into riser reactor 2, and the rest of the reaction conditions and The reaction results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com