Porous calcium phosphate support loaded microsphere composite material, as well as preparation method and application thereof

A technology of porous calcium phosphate and loaded microspheres, which is applied in the field of medicine to achieve the effect of reducing recurrence and treating bone and joint tuberculosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 3D printing of porous β-TCP scaffold and determination of its porosity

[0075] 1.1 3D printing of porous β-TCP scaffold

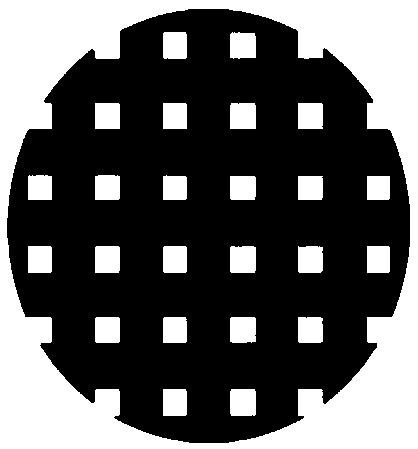

[0076] The porous β-TCP model to be printed is constructed by computer-aided design (CAD). Figure 1-1 to Figure 1-3 As shown, the use of β-tricalcium phosphate powder with a particle size of 2 μm, dilute citric acid, potassium dihydrogen phosphate, silicon dioxide, zinc oxide, and paraffin microspheres with a diameter of 2-8 μm (by mass percentage, the proportion is 55: 2.5:22.5:10:6.5:3.5), to prepare printing ink. A 750μm nozzle is selected, the walking speed is 100mm / min, the thickness of each layer is 750μm, and the intervals between layers on the X, Y, and Z axes are all 400μm. After spraying the β-TCP solution by the 3D-Bioplotter printer, the β-TCP stent was sintered at a constant temperature of 1100°C for 2 hours, and finally the finished product such as diagram 2-1 and Figure 2-2 shown. The cylindrical scaffold with a pore size of 4...

Embodiment 2

[0088] Preparation method and in vitro release of isoniazid and rifampicin sustained-release microspheres

[0089] 2.1 Preparation method of isoniazid and rifampicin sustained-release microspheres

[0090] Weigh 20 mg of isoniazid, 15 mg of rifampicin, 60 mg of PLGA and 600 mg of PVA (polyvinyl alcohol), put 600 mg of PVA into a small beaker and add 30 ml of ultrapure water, heat bath until PVA is completely dissolved, and use it as an adhesive for later use; The process of making microspheres by emulsion solvent evaporation method is as follows: Figure 4 As shown, isoniazid was added to 2ml of ultrapure water, vortexed for 3 minutes to mix well, and used as the water phase for later use; 2ml of dichloromethane was added to rifampicin and PLGA, and used as the oil phase for later use. Put the above into the refrigerator at 4°C for 1 hour, add the water phase to the oil phase, mix, homogenize, emulsify, accelerate the reaction, etc. through the ultrasonic breaker, then quickl...

Embodiment 3

[0096] PLGA anti-tuberculosis drug sustained-release microspheres loaded into porous β-TCP scaffold

[0097] Shake and stir the double-distilled water solution of PLGA anti-tuberculosis drug slow-release microspheres, mix the microspheres and add them to flat-bottomed centrifuge tubes, and place a piece of 3D printed porous β-TCP in the bottom of each centrifuge tube. Start the centrifuge, set the rotation speed to 4000rpm, and process for 15 minutes. After centrifugation, the PLGA anti-tuberculosis drug slow-release microspheres can enter all pores of the porous β-TCP scaffold until saturated. After centrifugation, discard the liquid and excess microspheres, then add 10% gelatin solution to the tube, and centrifuge at low speed for 15 minutes again. Capable of binding microspheres within the pores of porous β-TCP. After 24 hours of freeze-drying treatment, the 3D printed porous β-TCP loaded PLGA anti-tuberculosis drug sustained-release microsphere composite material was fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com