Preparation method for metal molybdate micro-nano structure powder

A micro-nano structure, metal molybdate technology, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry and other directions, can solve the problems of complex process, difficult mass preparation and large-scale production, etc. Good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

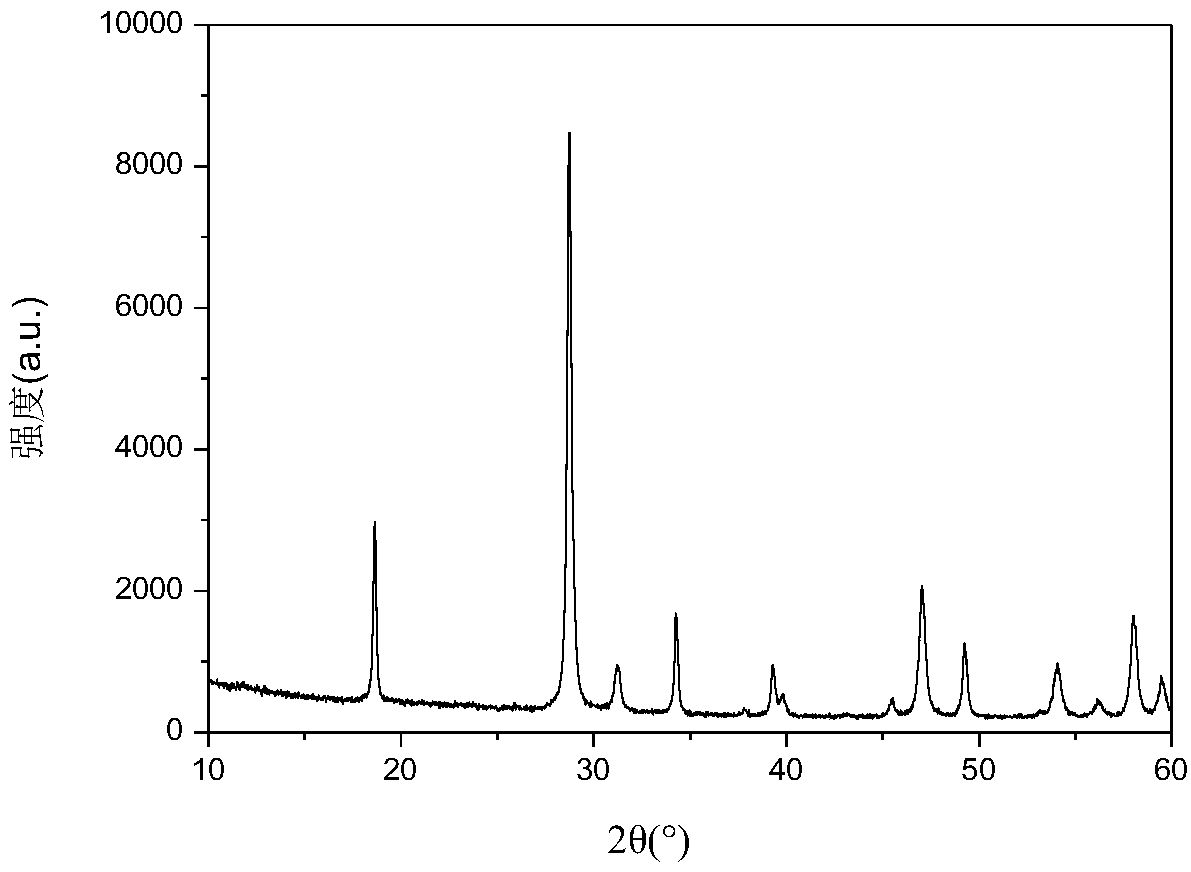

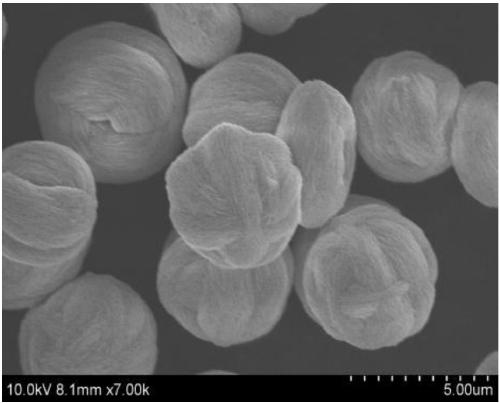

[0033] Dissolve 0.55g of anhydrous calcium chloride in a mixed solution of 70mL N,N-dimethylacetamide (DMAc) and deionized water, and the volume ratio of the two is 1:6, sonicate in an ultrasonic cleaner for 30min, weigh 6.18 g of ammonium heptamolybdate was dissolved in the ultrasonicated solution, and stirred at room temperature until the ammonium heptamolybdate was completely dissolved to obtain a colorless and transparent precursor solution. Pour the above precursor solution into a 100mL reaction kettle, react at 180°C for 30min, wait for the reaction kettle to cool down to room temperature, wash the prepared samples with deionized water and absolute ethanol for 3 times, and then bake at 80°C for 8 ~10h, calcium molybdate powder can be obtained. figure 1 In the X-ray diffraction spectrum of the calcium molybdate powder prepared for this example, all the diffraction peaks are completely consistent with the standard spectrum of calcium molybdate (JCPDS no 29-0351), and no i...

Embodiment 2

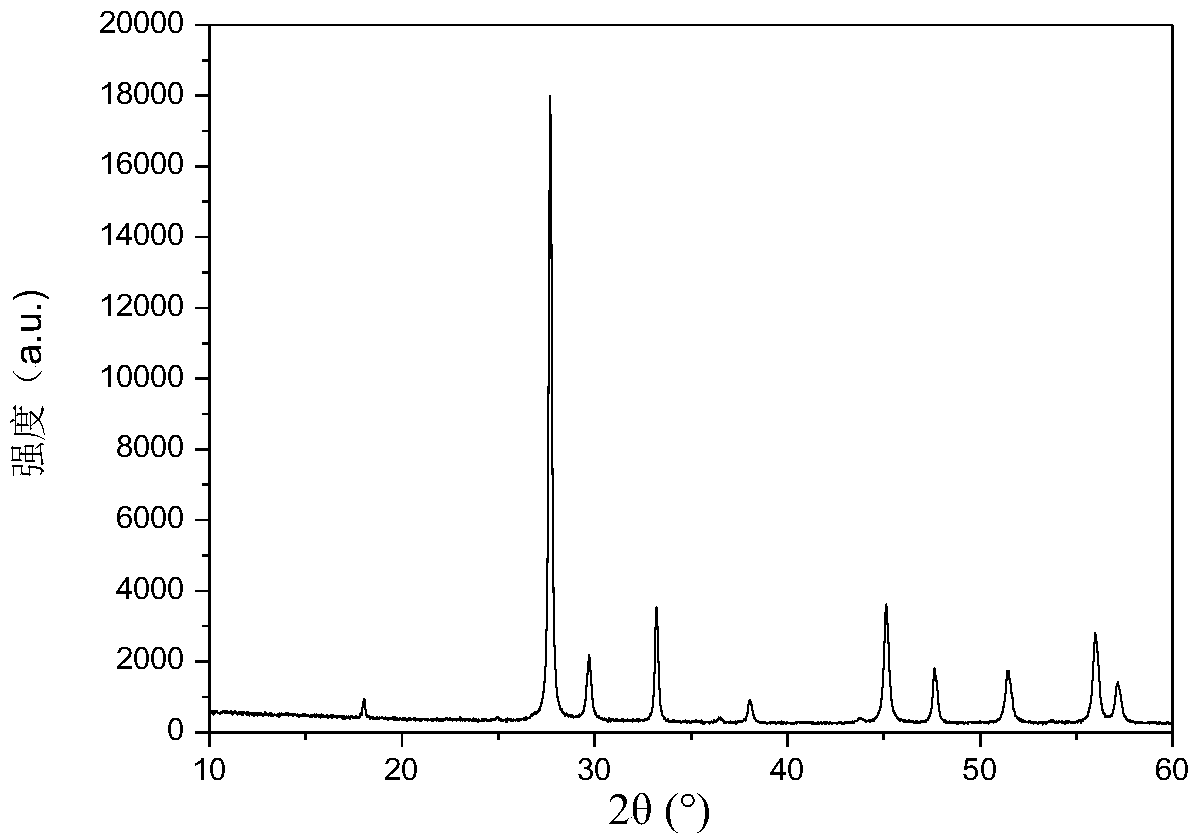

[0035]Dissolve 0.63g of strontium nitrate in a mixed solution of 70mL N,N-dimethylacetamide (DMAc) and deionized water, and the volume ratio of the two is 1:4, sonicate in an ultrasonic cleaner for 30min, and weigh 3.70g Ammonium heptamolybdate was dissolved in the ultrasonicated solution and stirred at room temperature until the ammonium heptamolybdate was completely dissolved to obtain a colorless and transparent precursor solution. Pour the above precursor solution into a 100mL reactor and react at 160°C for 16 hours. After the reactor is cooled to room temperature, wash the prepared samples with deionized water and absolute ethanol respectively, and then bake them at 80°C for 8~ After 10 hours, strontium molybdate powder can be obtained. image 3 In the X-ray diffraction spectrum of the strontium molybdate powder prepared for this example, all the diffraction peaks are completely consistent with the standard spectrum of strontium molybdate (JCPDS no 85-0586), and no impuri...

Embodiment 3

[0037] Dissolve 0.50g of barium acetate in a mixed solution of 70mL N-methylacetamide (MAc) and deionized water, and the volume ratio of the two is 1:2, sonicate in an ultrasonic cleaner for 30min, and weigh 2.47g of heptamolybdic acid Ammonium was dissolved in the ultrasonicated solution and stirred at room temperature until the ammonium heptamolybdate was completely dissolved to obtain a milky white precursor solution. Pour the above precursor solution into a 100mL reactor, react at 120°C for 20h, wait until the reactor is cooled to room temperature, wash the prepared samples with deionized water and absolute ethanol three times, and then bake at 80°C for 8~ After 10 hours, barium molybdate powder can be obtained. Figure 5 In the X-ray diffraction spectrum of the barium molybdate powder prepared for this example, all the diffraction peaks are completely consistent with the standard spectrum of barium molybdate (JCPDS no 29-0193), and no impurity peaks are found in the spect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com