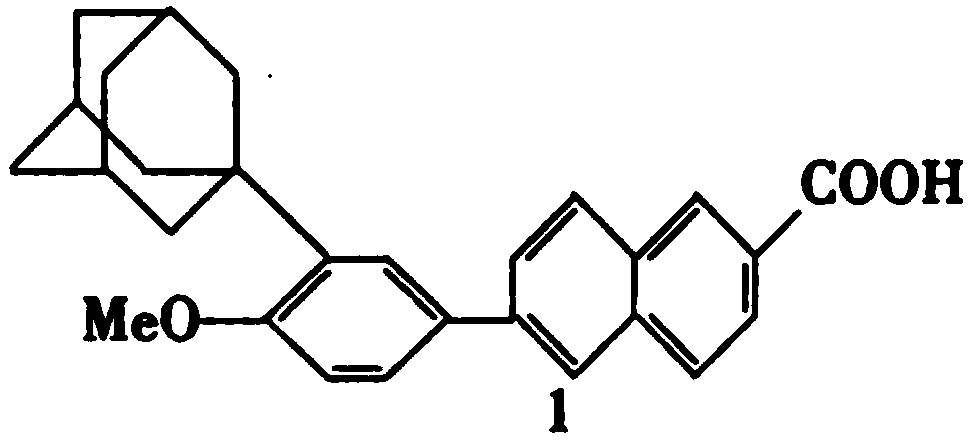

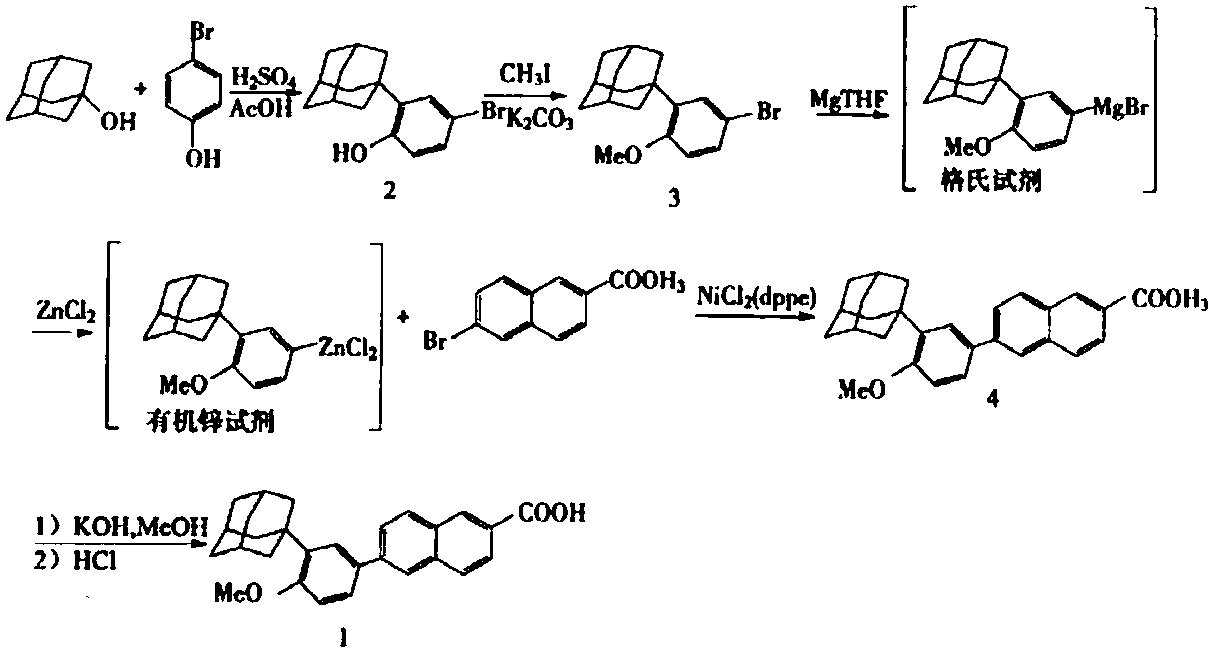

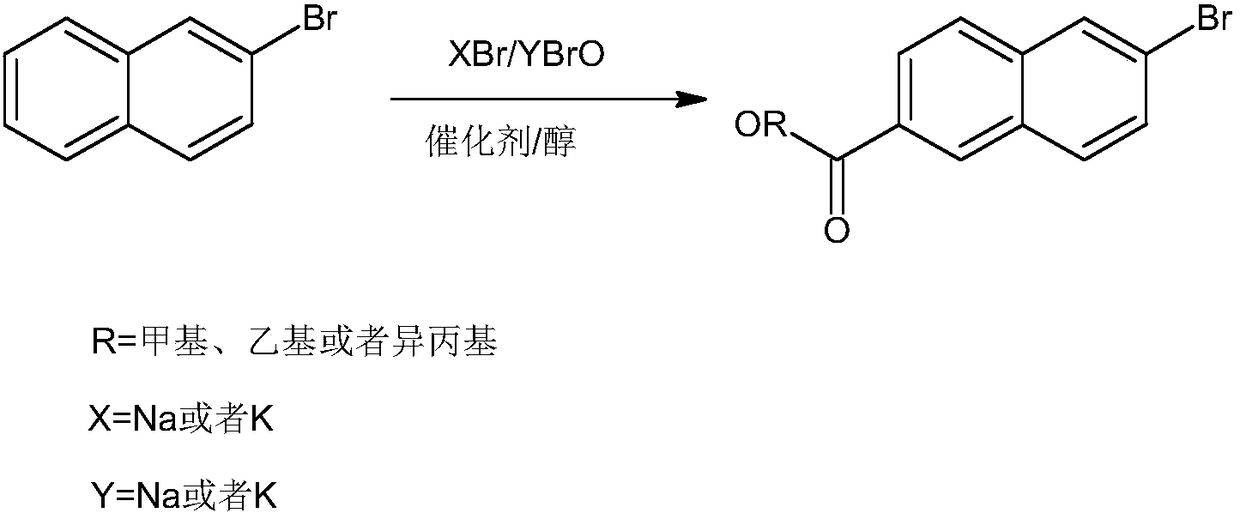

Method for synthesizing adapalene intermediate 6-bromo-2-naphthoate

A technology of adapalene and naphthoate, which is applied in the field of synthesis of adapalene intermediate 6-bromo-2-naphthoate, can solve the problems of low process yield and pollution discharge, and achieve reaction selection High solubility, less side effects, good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The synthetic method of 6-bromo-2-naphthoic acid methyl ester, comprises the following steps:

[0031] 1) Mix 2-naphthoic acid and methanol, add the catalyst, stir and pass in argon, control the pressure to 6 atmospheres, control the temperature to 150°C, and keep it for 60 minutes; start adding the mixture of sodium bromide and benzenesulfonic acid dropwise Aqueous solution, when the dripping volume reaches 8% of the solution volume, start to drop the sodium hypobromite aqueous solution; control the same dropping speed of the two solutions, and the total dropping time is 110min; after the dropping, the system is heated to 170°C , pressurized to 15 atmospheres to continue the reaction for 6h to end.

[0032] The catalyst is obtained by the following method: uniformly grinding nano-titanium dioxide and nano-silicon dioxide, soaking in hydrochloric acid with a mass concentration of 8% for 5 hours, filtering, washing with water, drying in the air, and drying at 300°C.

[...

Embodiment 2

[0036] The synthetic method of 6-bromo-2-naphthoic acid isopropyl ester comprises the following steps:

[0037] 1) Mix 2-naphthoic acid and isopropanol, add the catalyst, stir and pass nitrogen, control the pressure to 4 atmospheres, control the temperature to 130 ° C, and keep it for 50 minutes; start dropping potassium bromide and benzenesulfonic acid Mix the aqueous solution, and when the dropwise addition volume reaches 5% of the solution volume, start to drop the aqueous solution of potassium hypobromite; control the same dropping speed of the two solutions, and the total dropping time is 90min; The pressure was raised to 11 atmospheres and the reaction was continued for 5h to end.

[0038] The catalyst is obtained by the following method: uniformly grinding nano-titanium dioxide and nano-silicon dioxide, soaking in hydrochloric acid with a mass concentration of 5% for 3 hours, filtering, washing with water, drying in the air, and drying at 250°C.

[0039] The molar rati...

Embodiment 3

[0042] The synthetic method of 6-bromo-2-naphthoic acid ethyl ester, comprises the following steps:

[0043] 1) Mix 2-naphthoic acid and ethanol, add the catalyst, stir and pass in argon, control the pressure to 7 atmospheres, control the temperature to 155°C, and keep it for 70 minutes; start to add the mixture of sodium bromide and benzenesulfonic acid dropwise Aqueous solution, when the dropping volume reaches 10% of the volume of the solution, start to drop the sodium hypobromite aqueous solution; control the dropping speed of the two solutions to be the same, and the total dropping time is 150min; after the dropping, the system is heated to 180°C , the pressure was increased to 17 atmospheres and the reaction was continued for 7h to end.

[0044] The catalyst is obtained by the following method: uniformly grinding nano-titanium dioxide and nano-silicon dioxide, soaking in hydrochloric acid with a mass concentration of 10% for 6 hours, filtering, washing with water, drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com