Carbon quantum dot with silkworm excrement as raw material as well as preparation method and application of carbon quantum dot

A technology of carbon quantum dots and silkworm excrement, applied in chemical instruments and methods, analytical materials, luminescent materials, etc., can solve the problems of large size, long time, complicated purification process of fluorescent carbon dots, etc., achieve high yield and improve carbonization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

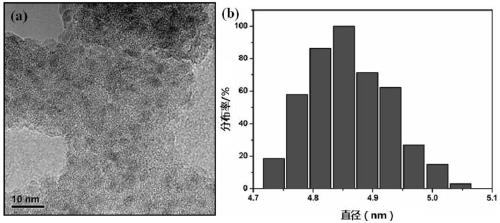

[0060] The preparation method of the carbon quantum dot powder based on silkworm excrement, it may further comprise the steps:

[0061] (1) After mixing 0.5g of silkworm excrement obtained by normal feeding of mulberry leaves with 5mL of concentrated sulfuric acid (the mass fraction of sulfuric acid in concentrated sulfuric acid is 98%), put it in a 25mL microwave reactor, add a magnet to stir or rotate the microwave The reactor is equipped with a turntable, microwave reaction under 500W power, and a dark yellow carbon quantum dot solution is obtained in 3 minutes;

[0062] (2) Filter to remove insoluble impurities, place the obtained reaction solution in a dialysis bag (1,000-10,000Da) for dialysis, and replace the deionized water for dialysis every 30 minutes, a total of 5 times, to obtain the CDs aqueous solution;

[0063] (3) Freeze-dry for 24 hours at -10°C to -50°C.

Embodiment 2

[0065] The preparation method of the carbon quantum dot powder based on silkworm excrement, it may further comprise the steps:

[0066] (1) After mixing 0.2g of silkworm excrement obtained by normal feeding of mulberry leaves with 5mL of concentrated nitric acid (the mass fraction of nitric acid in concentrated nitric acid is 68%), put it in a 25mL microwave reactor, add a magnet to stir or rotate the microwave The reactor is equipped with a turntable, microwave reaction under 100W power, and a dark yellow carbon quantum dot solution is obtained in 5 minutes;

[0067] (2) Filter to remove insoluble impurities, place the obtained reaction solution in a dialysis bag (1,000-10,000Da) for dialysis, and replace the deionized water for dialysis every 20 minutes, a total of 6 times, to obtain the CDs aqueous solution;

[0068] (3) Freeze-dry for 24 hours at -10°C to -50°C.

Embodiment 3

[0070] The preparation method of the carbon quantum dot powder based on silkworm excrement, it may further comprise the steps:

[0071] (1) After mixing 0.3 g of silkworm excrement obtained by normal feeding of mulberry leaves with 5 g of phosphorus pentoxide aqueous solution (now prepared and used, the mass fraction of phosphorus pentoxide is 60%), place in a 25mL microwave reaction kettle, Add magnets to stir or rotate the supporting turntable of the microwave reactor, microwave reaction at 700W power, and obtain a dark yellow carbon quantum dot solution in 10 minutes;

[0072] (2) Filter to remove insoluble impurities, place the obtained reaction solution in a dialysis bag (1,000-10,000Da) for dialysis, and replace the deionized water for dialysis every 25 minutes, a total of 7 times, to obtain the CDs aqueous solution;

[0073](3) Freeze-dry for 24 hours at -10°C to -50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com