Using method of compound mineral medicament

A technology of minerals and chemicals, applied in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of pH control lag, alum not easily precipitated, secondary pollution of membrane equipment, etc. Achieve the effects of stable pH fluctuation control, avoiding re-engineering investment, and low long-term operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

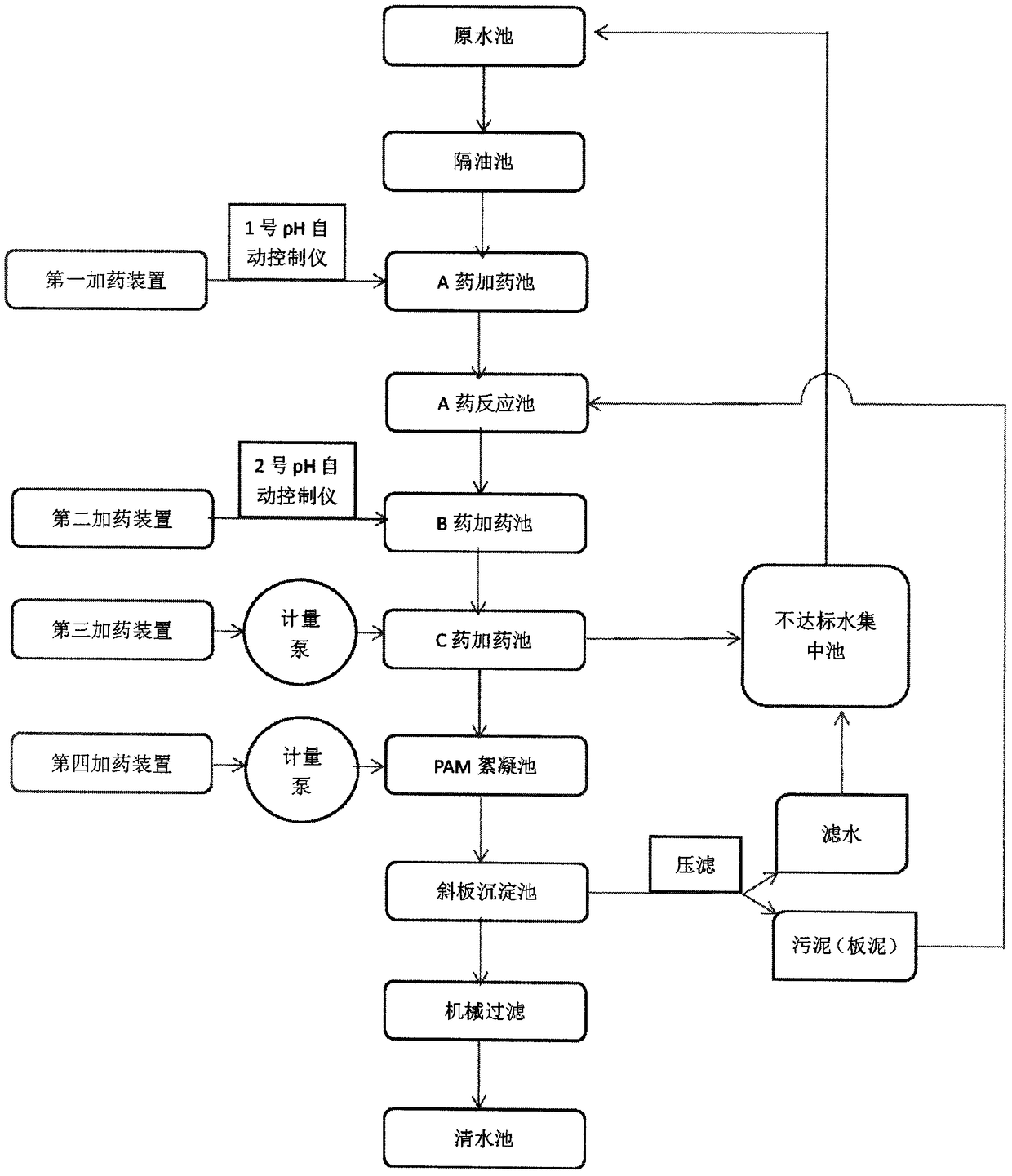

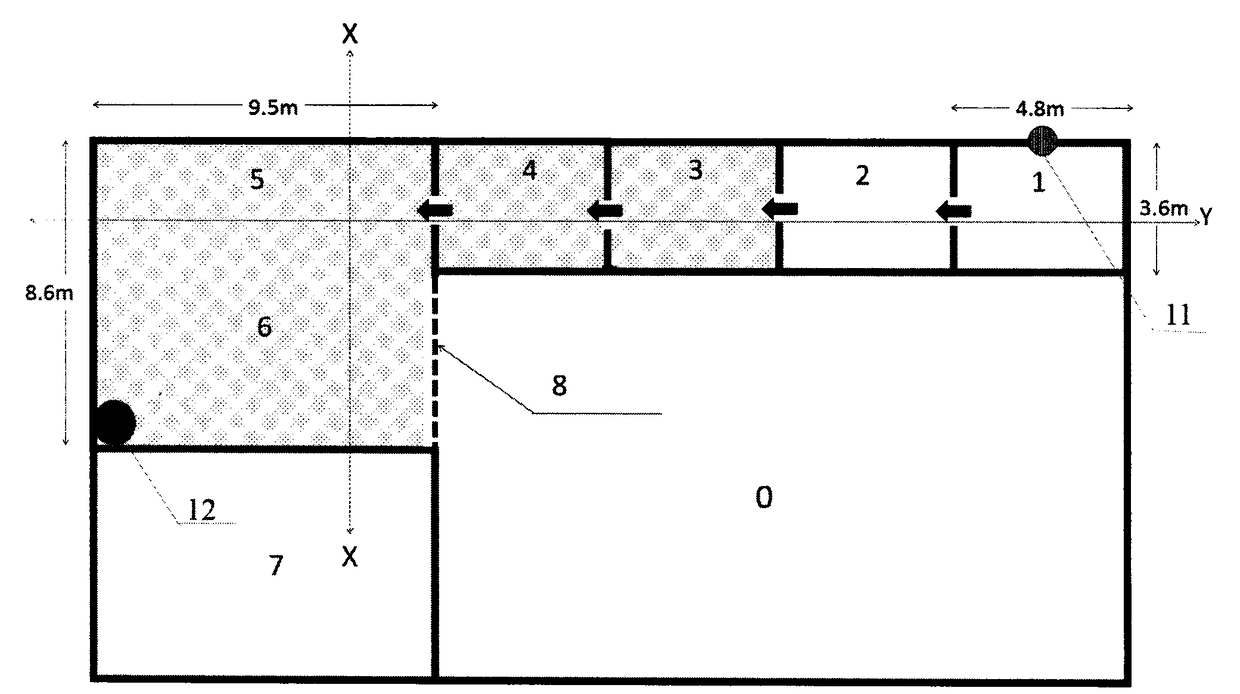

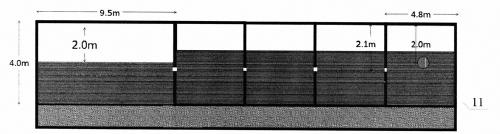

[0051] Embodiment 1, a certain lead-acid battery enterprise A, according to the present invention, the sewage tank system of the enterprise has been transformed, such as figure 2 As mentioned above, the lead-acid wastewater enters the grease trap 1 from the raw water pool 0, the A medicine dosing pool 2, the A medicine reaction pool 3, the B medicine dosing pool 4, the C medicine dosing pool 5, polyacrylamide (PAM) flocculation pool 6 and inclined plate sedimentation tank 7. Among them, the oil separation tank 1 is not equipped with an aeration device; and the A drug dosing tank 2, the A drug reaction tank 3 and the B drug dosing tank 4 need to install an aeration device, and the aeration should be sufficient. When installing the aeration, each original The pool should be constructed separately according to the actual size and put in the aeration device. Among them, the drug A reagent delivery point is arranged at the opposite side of the two relatively slow water flows to e...

Embodiment 2

[0055] Embodiment 2, a certain lead-acid battery enterprise B, according to the present invention, the sewage tank system of the enterprise has been transformed, wherein the aeration pipe is in charge of PPR50, the middle is the secondary pipe PPR32 pipe, the air pressure inlet and outlet is PPR65 pipe, and the aeration air pressure is 6.0kg , the distance between the pipe and the pipe is 30cm, the main and auxiliary pipes face down at a 45-degree angle, and the distance is 15cm, and the holes are alternately punched, and the aeration eye (hole) is 4.2mm. The distance between the aeration pipe and the wall of the sewage tank is 20cm, and the distance between the aeration pipe and the bottom is about 25cm. The aeration pipe is placed in the pool after drilling holes on the ground, pressed with waste marble, and inserted into the marble to fix it. When each aeration pipe is put into the raw water tank, a valve switch needs to be installed on the opposite corner. The A drug dosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com