Extraction method of auricularia auricula polysaccharides and preparing method of preparations of auricularia auricula polysaccharides

A fungus polysaccharide and extraction method technology, applied in the field of biomedicine, can solve the problems of loss of active components, difficult separation of material and liquid, unfavorable dissolution of active components, etc., and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

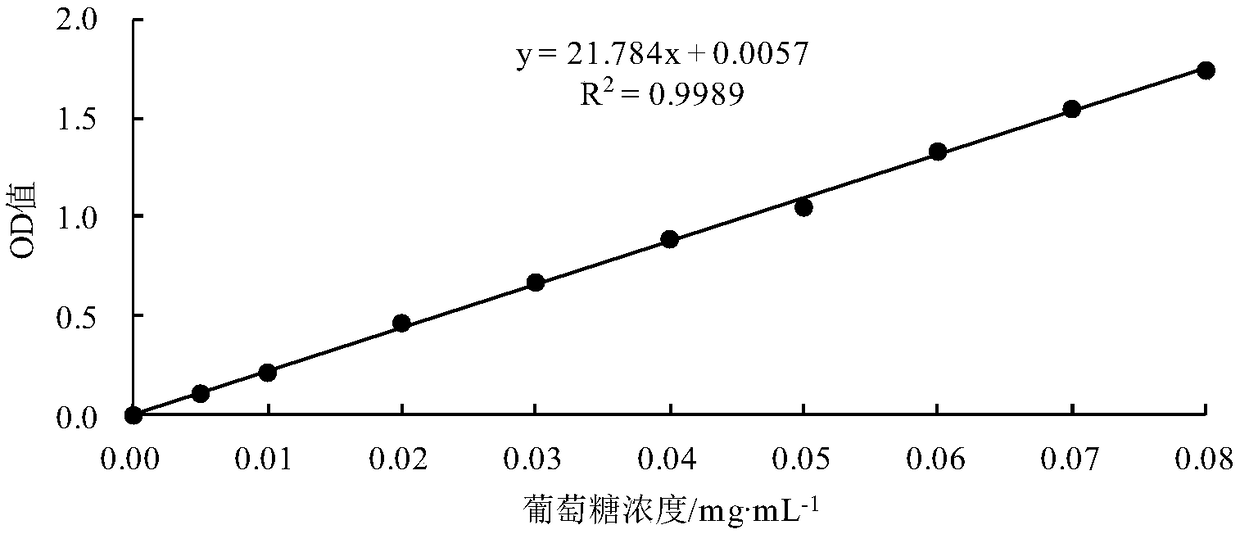

Method used

Image

Examples

Embodiment 1

[0026] Bake 500g of dry black fungus raw material at a temperature of 75°C for 180min, then ultrafinely pulverize it to a particle size of 100 mesh, add water 40 times the weight ratio and soak for 30min, extract at a temperature of 100°C, extract for 1h, and centrifuge the extract at 5000rpm , vacuum-dried to obtain 52.8g of fungus polysaccharide, which was crushed into fine powder, added an appropriate amount of auxiliary materials such as starch and dextrin, mixed evenly, made into granules, and packed into hard capsules to obtain 1000 capsules.

Embodiment 2

[0028] Bake 800g of dried black fungus raw material at a temperature of 95°C for 30 minutes, then ultrafinely pulverize it to a particle size of 200 mesh, add water 30 times the weight ratio and soak for 90 minutes, extract at a temperature of 95°C, extract for 3 hours, and centrifuge the extract at 3000rpm , vacuum-dried to obtain 72.2g of fungus polysaccharide, crushed into fine powder, added appropriate amount of starch, dextrin and other auxiliary materials, mixed, wet granulated, granulated after drying, packaged to obtain 1000g granules.

Embodiment 3

[0030] Bake 650g of dried black fungus raw material at a temperature of 85°C for 60 minutes, then ultrafinely pulverize it to a particle size of 160 mesh, add water 35 times the weight ratio and soak for 60 minutes, extract at a temperature of 98°C, extract for 2 hours, and centrifuge the extract at 4000rpm , vacuum-dried to obtain 78.1g of fungus polysaccharide, crushed into fine powder, added appropriate amount of starch, dextrin and other auxiliary materials, mixed evenly, made into granules, and pressed into tablets to obtain 1000 preparations.

[0031] Example 1

[0032] 650g of dried black fungus raw materials were ultrafinely pulverized to a particle size of 160 mesh, soaked in 35 times of water by weight for 60 minutes, extracted at 98°C for 2 hours, centrifuged at 4000rpm, and dried in vacuum to obtain 35.9g of fungus polysaccharides. Crush it into fine powder, add appropriate amount of auxiliary materials such as starch and dextrin, mix well, make granules, and press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com