Acidophilic bioleaching microorganism inclusion and preparation method thereof

A technology of microorganisms and embeddings, which is applied in the direction of fixing on/in the organic carrier, which can solve the problems that it is difficult to take into account the continuous output of high-activity and high-cell-concentration microbial solutions, and the easy loss of microorganisms, so as to increase the expansion rate of fillers , not easy to lose, maintain a large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for immobilizing microorganisms, comprising the steps of:

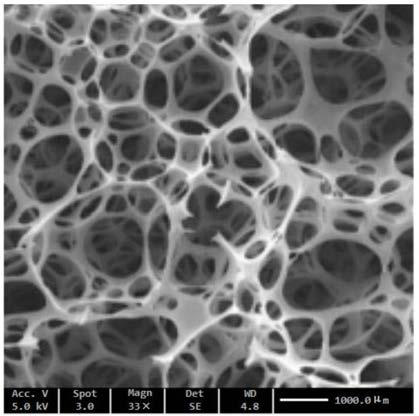

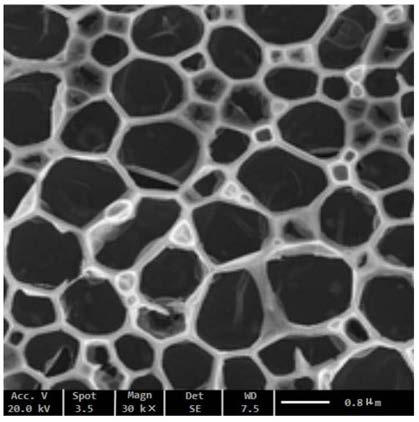

[0034] Step 1. Weigh 10g of sodium alginate, add 500mL of distilled water after mixing, and heat it in a microwave oven to dissolve completely. When the temperature is cooled to 50°C, add 3g of micro-nano potassium carbonate with an average particle size of 266nm, and stir evenly to obtain an embedding suspension Solution A, keep warm at 45°C;

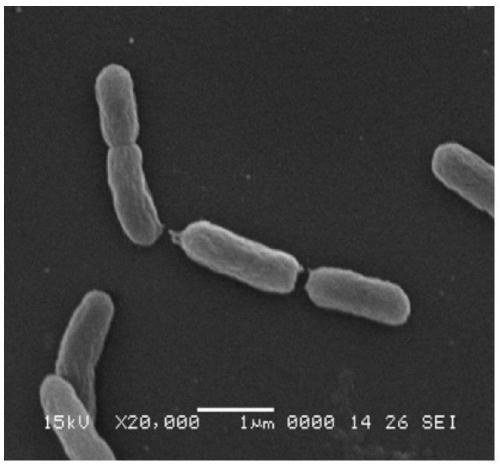

[0035] In step 2, 10 L of cultured Leptospirillum ferriphilum YSK and Sulfobacillus thermosulfidooxidans YN22 were centrifuged at 10,000 × g for 20 minutes in a high-speed centrifuge to collect the sludge, and used 500L of dilute sulfuric acid suspended bacteria sludge with pH 2.0 to obtain 3.6×10 9 Individual / mL microbial suspension B;

[0036] Step 3, weigh 20g of calcium chloride, dissolve it in distilled water, and set the volume to 500mL to obtain cross-linking solution C;

[0037] Step 4, weigh 1.5g of ammonium sulfate, 0.25g of magnesium sulfate, 0.25...

Embodiment 2

[0043] A method for immobilizing microorganisms, comprising the steps of:

[0044] Step 1: Weigh 20g of polyvinyl alcohol and 30g of sodium alginate respectively, add 1L of distilled water after mixing, heat in a microwave oven to dissolve completely, and when the temperature cools down to 50°C, add 5g of sodium carbonate powder, the particle size of which is less than 5μm, and stir Obtain embedding suspension A evenly and keep it warm at 30°C;

[0045] Step 2: Concentrate 50L of cultured Acidithiobacillus ferrooxidans ATCC23270 through a ceramic membrane reactor with a pore size of 0.1 μm to 5L, and then centrifuge the concentrated bacterial solution through a high-speed centrifuge at 10,000×g for 20 minutes to collect the sludge , with 1L of dilute sulfuric acid at pH 2.0 to suspend the sludge to obtain 1.3×10 10 Individual / mL microbial suspension B;

[0046] Step 3, weigh 30g of calcium chloride and 25g of boric acid, dissolve them in distilled water, and set the volume t...

Embodiment 3

[0054] A method for immobilizing microorganisms, comprising the steps of:

[0055] Step 1, weigh 5g of polyvinyl alcohol, 5g of polyoxyethylene and 10g of sodium alginate, mix and add 1L of distilled water, heat it in a microwave oven to dissolve completely, when the temperature is cooled to 50°C, add 5g of nano-sodium bicarbonate powder , the average particle size is about 280nm, stir evenly to obtain embedding suspension A, keep warm at 45°C;

[0056] Step 2: Concentrate 50L of the cultured Sulfobacillus acidophilus TPY to 5L through a ceramic membrane reactor with a pore size of 0.1 μm, and then centrifuge the concentrated bacterial solution through a high-speed centrifuge at 10,000×g for 20 minutes to collect the sludge , with 1L of dilute sulfuric acid at pH 2.0 to suspend the sludge to obtain 2.1×10 10 Individual / mL microbial suspension B;

[0057] Step 3, weigh 30g of calcium chloride and 20g of boric acid, dissolve them in distilled water, and set the volume to 1L to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com