Nanoporous amorphous-state electrocatalytic electrode and preparation method and application thereof

A nanoporous, electrocatalytic technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of low activity and poor stability of electrocatalysts, and achieve the effects of avoiding catalyst shedding, avoiding activity reduction, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

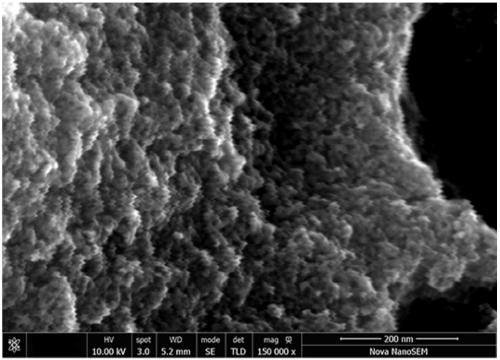

[0033] A method for preparing a nanoporous amorphous Fe-B electrocatalytic electrode, comprising the following steps:

[0034] Step 1: Put Fe, B, and iron-boron compounds in a high-temperature electric furnace, the molar ratio of iron and boron is 3:1, stir evenly after melting, and cool down to obtain an electrocatalytic electrode alloy;

[0035] Step 2: Melt the alloy obtained in Step 1 again, and carry out liquid-phase quenching on a rotating copper disk with a cooling rate of 10 5 K / s, rotating speed is 2500rpm, obtains amorphous Fe-B electrocatalytic electrode;

[0036] Step 3: Soak the amorphous electrocatalytic electrode obtained in step 2 in 50 mM nickel nitrate, and react at 25° C. for 30 minutes to obtain a nanoporous amorphous electrocatalytic electrode.

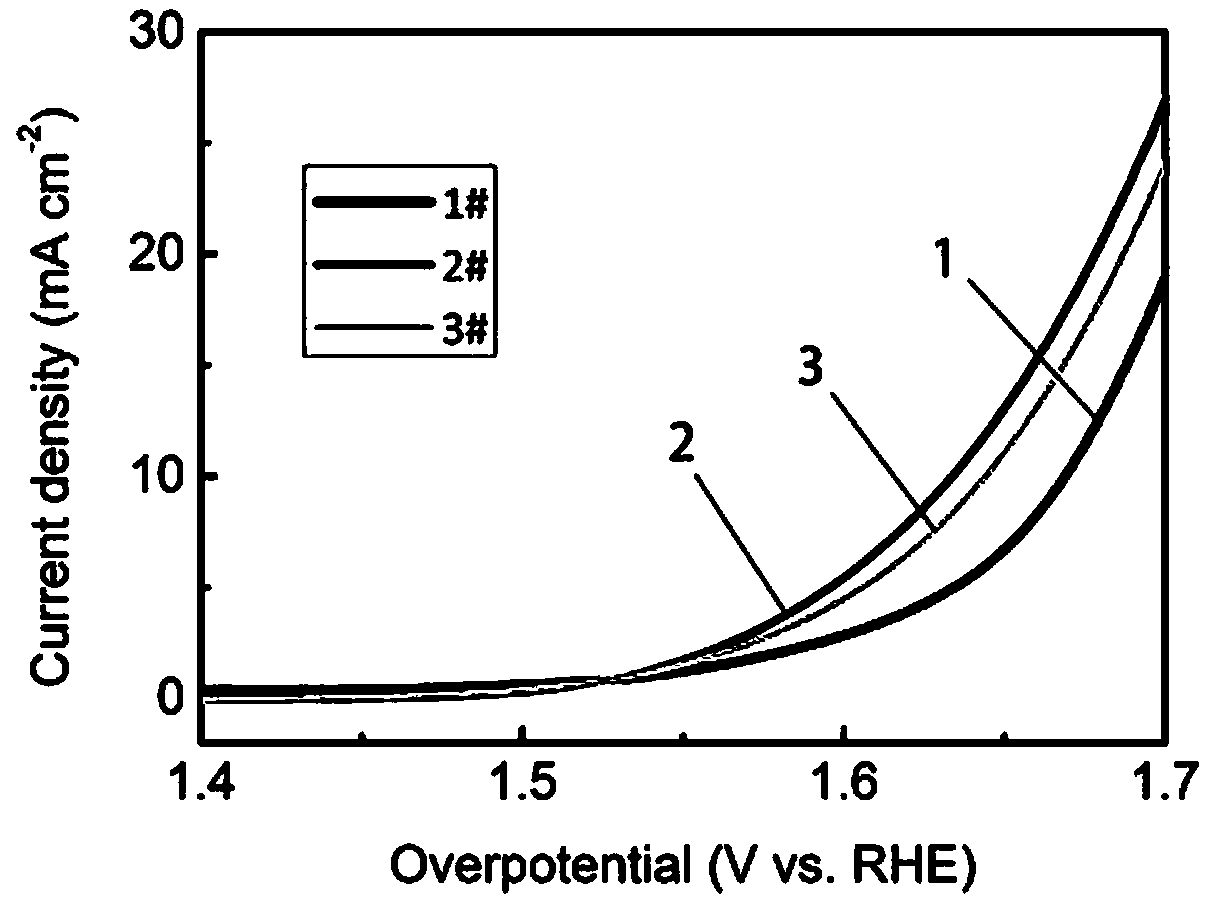

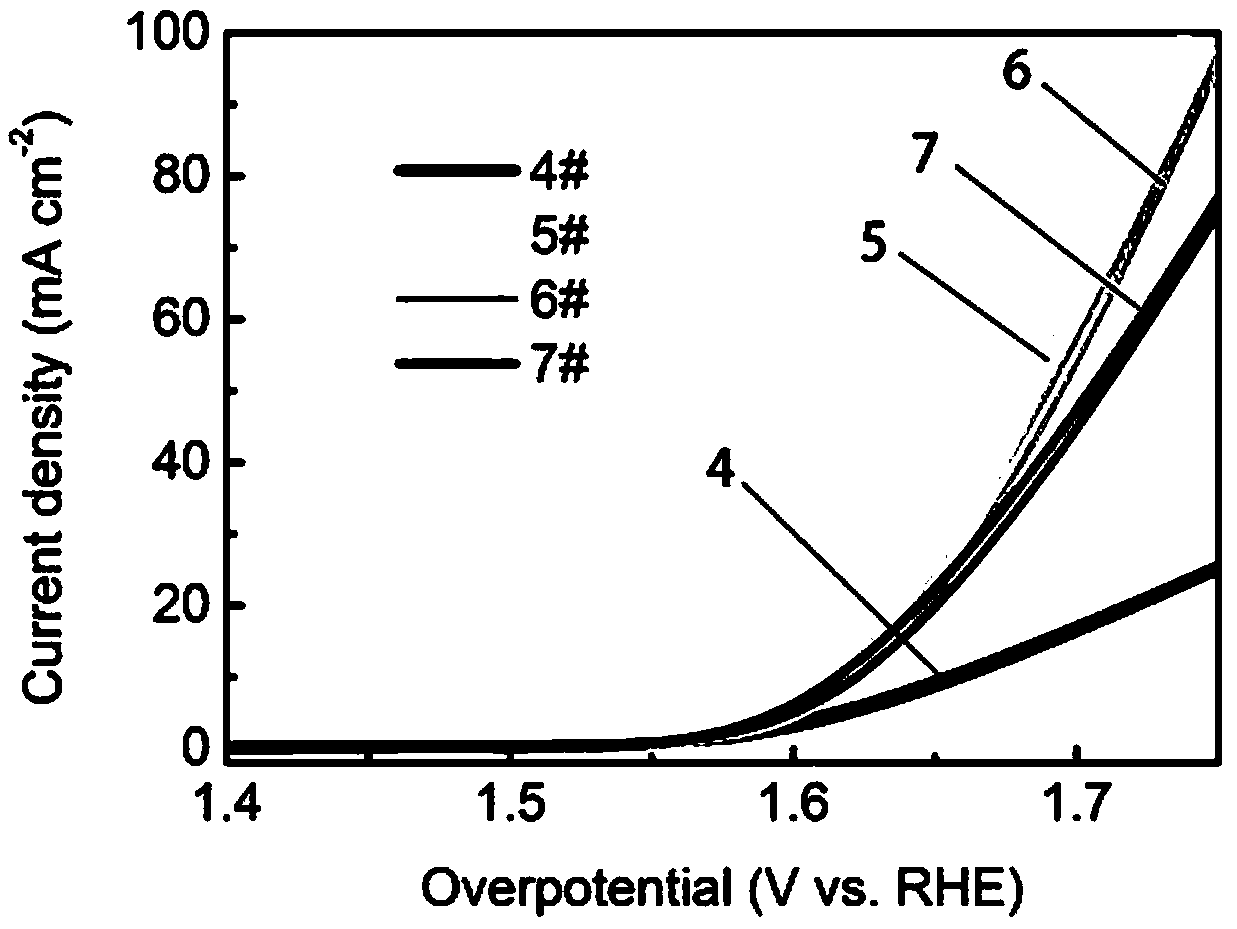

Embodiment 2

[0038] A method for preparing a nanoporous amorphous Fe-B electrocatalytic electrode is basically the same as that of Example 1, except that the reaction condition in Step 3 is 30 minutes at 50°C.

Embodiment 3

[0040]A method for preparing a nanoporous amorphous Fe-B electrocatalytic electrode is basically the same as that of Example 1, except that the reaction condition in Step 3 is 180 minutes at 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com