A kind of g-c3n4 crystalline phase/amorphous homogeneous junction and its preparation method and application

A technology of C3N4 and g-c3n4, applied in the direction of chemical instruments and methods, non-metallic elements, chemical/physical processes, etc., can solve the problems of increased complexity and difficulty, difficult growth control, complicated preparation process, etc., to reduce the preparation energy Consumption, low price, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1.1 Heat 10 g of melamine to 600 °C at a heating rate of 2 °C / min and keep it warm for 2 hours to obtain a block carbon nitride precursor.

[0034] 1.2. Grind the bulk carbon nitride precursor in the above step 1.1 until it is powdered, take 2 g and disperse it in 5 ml deionized water, and process it ultrasonically for 1 h.

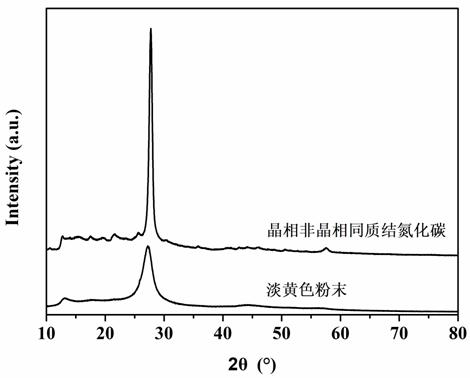

[0035] 1.3. Transfer the suspension in step 1.2 to a petri dish, and freeze-dry (i.e., vacuum freeze-dry) under the conditions of a vacuum degree of less than 20Pa and a freezing temperature of less than -20°C to obtain a light yellow powder.

[0036] 1.4. Heat the light yellow powder obtained in the above step 1.3 to 650°C at a heating rate of 60°C / min under the protection of argon gas, and then raise it to 700°C at a heating rate of 0.5°C / min and keep it warm for 2 hours. Afterwards, it is naturally cooled with the furnace to obtain the final carbon nitride product.

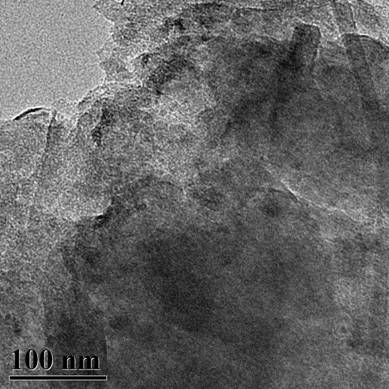

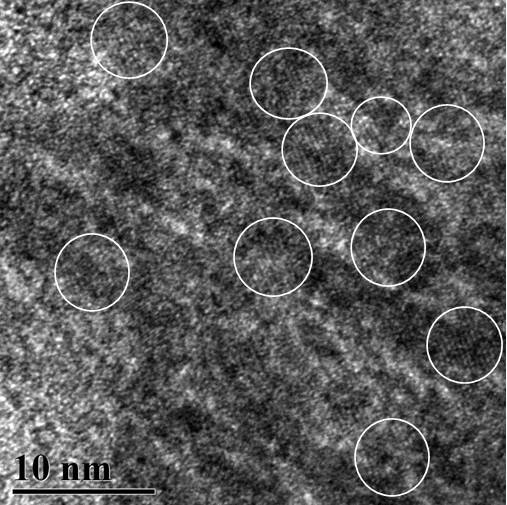

[0037] figure 1 with figure 2 It is the HRTEM diagram of the final product....

Embodiment 2

[0040] According to the method for embodiment 1, prepare crystalline phase / amorphous homogeneous junction carbon nitride (also referred to as C 3 N 4 homogeneous junction, the same below), the difference is: replace melamine with dicyandiamide, and at the same time ensure that 2 g of block carbon nitride can be obtained. The resulting homojunction carbon nitride morphology and figure 2 Similarly, it is a crystalline phase and an amorphous homogeneous junction structure. The size of carbon nitride nanosheets is 300-500 nm and the thickness is 5-30 nm. Calculated crystal phase C 3 N 4 with amorphous phase C 3 N 4 The area ratio between them is 1:4.

Embodiment 3

[0042] Crystal phase / amorphous homogeneous junction carbon nitride was prepared according to the method of Example 1, except that melamine was replaced by urea, and at the same time, it was ensured that 2 g of block carbon nitride could be obtained. The resulting homojunction carbon nitride morphology and figure 2 Similarly, it is a crystalline phase and an amorphous homogeneous junction structure. The size of carbon nitride nanosheets is 300-500 nm and the thickness is 5-30 nm. Calculated crystal phase C 3 N 4 with amorphous phase C 3 N 4 The area ratio between them is 1:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com