A preparation method of an edible fresh-keeping film and an application of the film in material fresh-keeping

A technology of fresh-keeping film and chitosan, which is applied in application, food preservation, food science, etc., can solve the problems of difficult to meet people's demand for food, poor gas barrier and antibacterial properties, poor oil, water, and gas barrier effects, etc. problems, to achieve the effect of facilitating the combination of membrane molecules, improving cross-linking strength, and increasing shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

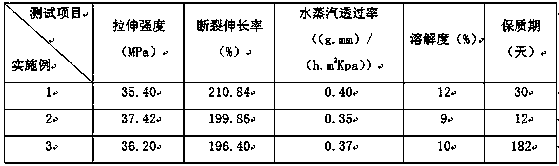

Examples

Embodiment 1

[0037] The degree of deacetylation of the chitosan powder of the present embodiment is 94%, the viscosity is 88mPa·s, and the moisture content is 7%.

[0038](1) Take 7 parts of chitosan powder, dissolve in 10 times the volume of sodium acetate buffer solution to prepare chitosan reaction solution, add 7 parts of ferulic acid powder, stir in a water bath oscillator at 50°C, 120rpm for 5min, Add 0.21 parts of laccase solution, place it in a microwave accelerated reaction device, and react for 5 hours; after the reaction is completed, centrifuge at 120 rpm for 5 minutes to remove impurities, and add 1 mol / L NaOH solution until the precipitation in the supernatant does not increase. Centrifugally wash the precipitate with a large amount of distilled water for 15 minutes, then extract with methanol for 12 hours to remove incompletely reacted phenol, wash away the methanol with distilled water, and freeze-dry to obtain laccase-modified chitosan powder;

[0039] The sodium acetate p...

Embodiment 2

[0048] (1) Take 10 parts of the above-mentioned chitosan powder, dissolve in 10 times the volume of sodium acetate buffer solution to prepare the chitosan reaction solution, add 10 parts of ferulic acid powder, and stir in a water bath oscillator at 55 °C at 120 rpm for 5 minutes , add 0.3 parts of laccase solution, place it in a microwave accelerated reaction device, and react for 6 hours; after the reaction is completed, centrifuge at 120rpm for 5 minutes to remove impurities, and add 1mol / L NaOH solution until the supernatant does not increase in precipitation. Centrifugally wash the precipitate with a large amount of distilled water for 10-15 minutes, then extract with methanol for 12 hours to remove incompletely reacted phenol, wash away the methanol with distilled water, and freeze-dry to obtain laccase-modified chitosan powder;

[0049] The sodium acetate pH is 5.0; the laccase activity is 1000u / g; the microwave heating temperature is 75°C, the microwave power is 320w, a...

Embodiment 3

[0058] (1) Take 7 parts of chitosan powder, dissolve in 10 times the volume of sodium acetate buffer solution to prepare chitosan reaction solution, add 7 parts of ferulic acid powder, stir in a water bath oscillator at 50°C, 120rpm for 5min, Add 0.21 parts of laccase solution, place it in a microwave accelerated reaction device, and react for 5 hours; after the reaction is completed, centrifuge at 120 rpm for 5 minutes to remove impurities, and add 1 mol / L NaOH solution until the precipitation in the supernatant does not increase. Centrifugally wash the precipitate with a large amount of distilled water for 15 minutes, then extract with methanol for 12 hours to remove incompletely reacted phenol, wash away the methanol with distilled water, and freeze-dry to obtain laccase-modified chitosan powder;

[0059] The sodium acetate pH is 5.0; the laccase activity is 800u / g; the microwave heating temperature is 70°C, the microwave power is 300w, and the reaction time is 10min;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com