A kind of inkjet nano silver conductive ink and preparation method thereof

A technology of conductive ink and nano-silver, which is applied in ink, household utensils, applications, etc., can solve the problems affecting the application of water-based inkjet nano-silver conductive ink, poor adhesion of water-based inkjet nano-silver conductive ink, etc., and achieve good conductivity , Surface tension reduction, anti-freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the inkjet printing nano-silver conductive ink of the present invention mainly includes two steps: firstly, preparing nano-silver powder, adding an auxiliary agent to the inorganic silver salt solution, stirring and then adding a reducing agent to obtain nano-silver particles, and then washing Then the nano silver paste is obtained, and the nano silver powder is obtained after drying at low temperature; the second is to prepare a mixed solution of various auxiliary agents and co-solvents, then add the nano silver powder, and stir evenly to obtain the inkjet nano silver conductive ink. The preparation process is simple, the nano-silver conductive ink has good dispersibility, excellent stability, suitable rheological properties, can achieve smooth ink jetting, and has good electrical conductivity and adhesion.

[0044] An inkjet printing nano-silver conductive ink and a preparation method thereof provided by the present invention comprise the foll...

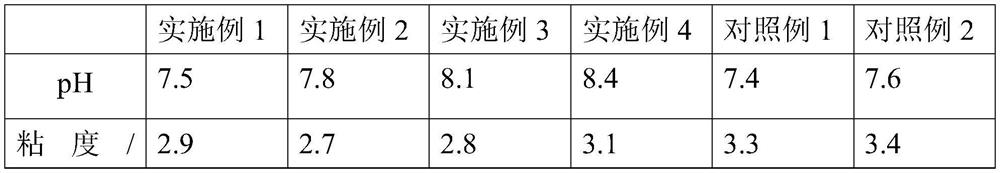

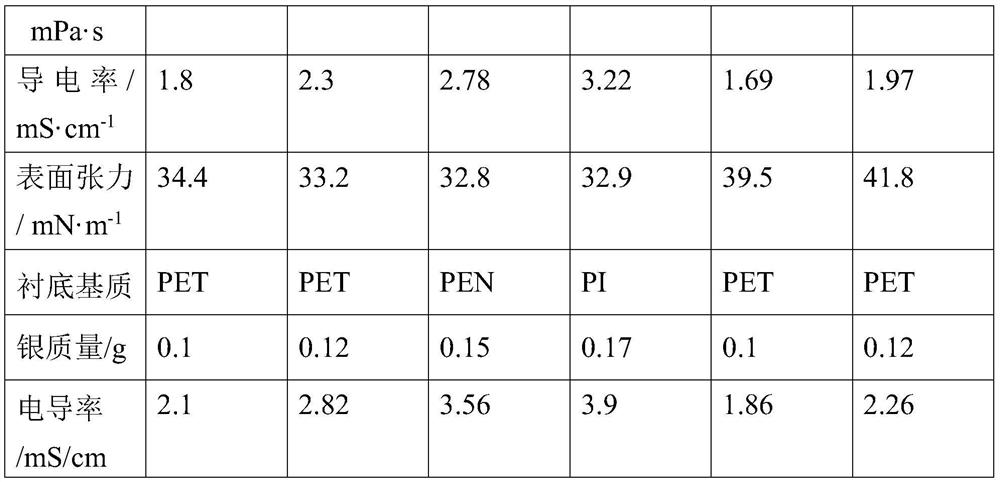

Embodiment 1

[0077] The inkjet nano silver conductive ink provided by the present invention is prepared according to the following parts by weight: 17 parts of nano silver, 69.6 parts of deionized water, 0.1 part of cosolvent, 0.6 part of wetting and dispersing agent, 2.0 parts of binder, 0.5 part of foaming agent, 3.0 part of moisturizing agent, 0.3 part of leveling agent, 0.4 part of anti-settling agent, and 0.5 part of viscosity modifier.

[0078] S1. The preparation method of nano-silver powder is as follows: prepare 0.4mol·L at room temperature -1 200mL of silver nitrate deionized aqueous solution, stirred for 5 minutes; then added polyvinylpyrrolidone, 0.2mol / l sodium polyacrylate dispersant 0.6mL, 1 part of auxiliary dispersant diethanolamine, 1.5ml, and stirred for 15 minutes to obtain silver nitrate- Dispersant mixed solution, the solution was heated to 50 ℃; prepare 2mol·L -1 30mL of sodium borohydride deionized aqueous solution; at 1500rpm min -1 Under the stirring speed, the ...

Embodiment 2

[0087] A water-based inkjet nano-silver conductive ink, prepared according to the following parts by weight: 20 parts of nano-silver, 70 parts of deionized water, 0.12 parts of cosolvent, 0.7 parts of wetting and dispersing agent, 2.2 parts of binder, and 0.55 parts of defoamer 5.0 parts of moisturizing agent, 0.4 part of leveling agent, 0.6 part of anti-settling agent, and 0.45 part of viscosity modifier.

[0088] S1. The preparation method of nano-silver powder is as follows: prepare 0.4mol·L at room temperature -1 400mL of silver nitrate deionized aqueous solution, stirred for 5 minutes; then add cetyltrimethylammonium bromide activator, 0.6mL of hydroxymethyl cellulose of 0.2mol / l, 2 parts of auxiliary dispersant diethanolamine, 3ml, Stir for 15 minutes to obtain a mixed solution of silver nitrate and dispersant, and heat the solution to 50 °C; prepare 2 mol·L -1 30mL of sodium borohydride deionized aqueous solution; at 1500rpm min -1 Under the stirring speed, the sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com