Genetically engineered bacterium producing L-isoleucine, construction method and application thereof

A technology of genetically engineered bacteria and isoleucine, which is applied in the field of genetically engineered bacteria producing L-isoleucine and its construction, can solve problems such as insufficient capacity, and achieve the effects of reducing production costs and widening industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

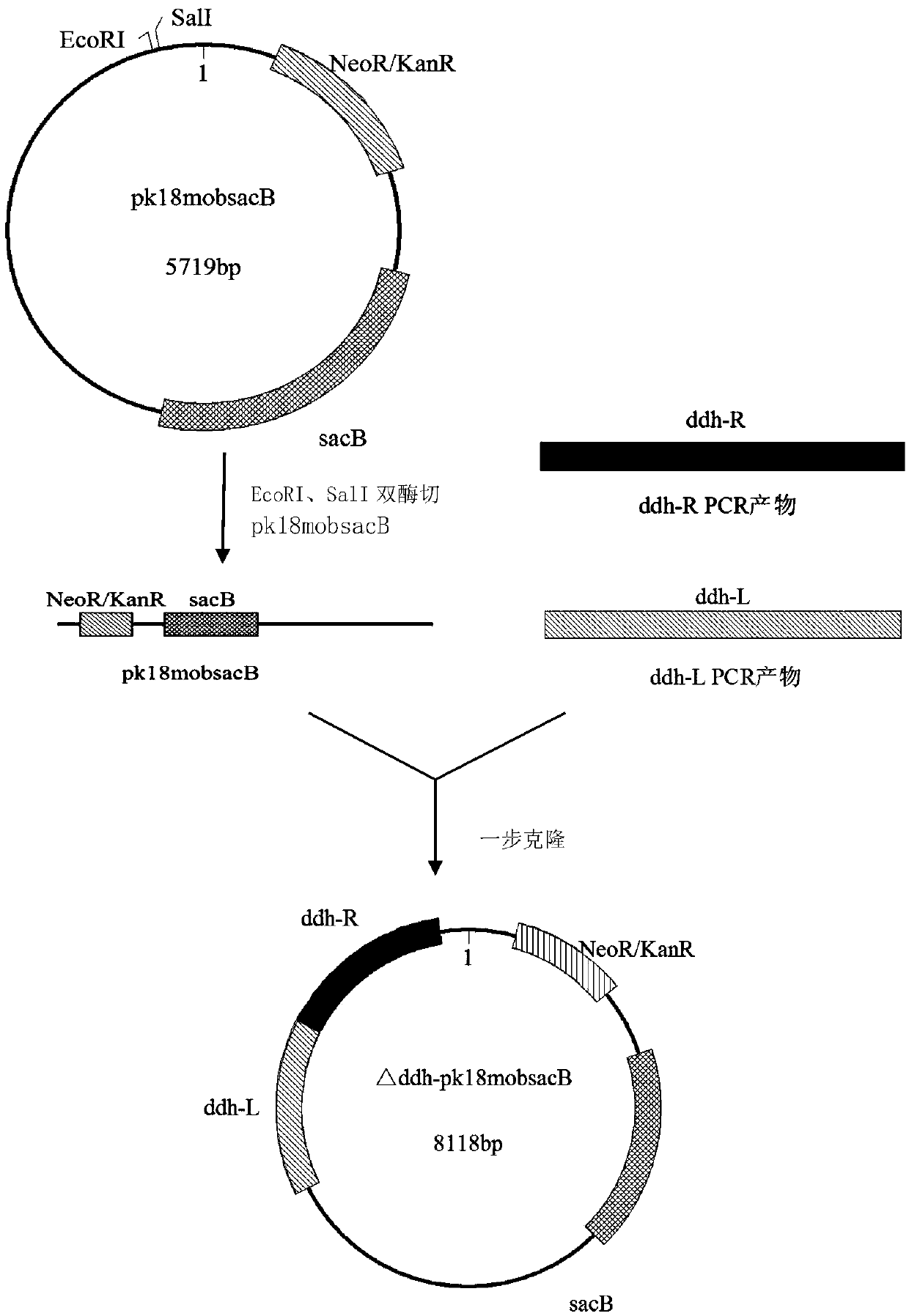

[0046] Example 1 Construction of Δddh-pk18mobsacB recombinant plasmid

[0047] This example constructs the Δddh-pk18mobsacB recombinant plasmid, which contains the upstream and downstream fragments of the ddh gene encoding diaminopimelate dehydrogenase, and the transposable gene mob and sucrose-sensitive gene that act on homologous recombination in Corynebacterium glutamicum The gene sacB.

[0048] The plasmid pk18mobsacB was digested with EcoRI / SalI double enzymes (the plasmid pk18mobsacB was purchased from Wuhan Miaoling Biotechnology Co., Ltd.), and the reaction system was: plasmid 1 μg, 10×buffer 5 μl, EcoRI 1 μl, SalI 1 μl, and water to 50 μl. Enzyme digestion at 37°C for 5h. 1% agarose gel electrophoresis detection and DNA gel recovery and purification kit to recover 5.6kb nucleotide fragments;

[0049] Compared with the standard strain C. glutamicum ATCC 13032, the glycerol-preserved strain C. glutamicum H5ΔargGΔalaT::ilvC (self-constructed strain, see patent CN 10670...

Embodiment 2

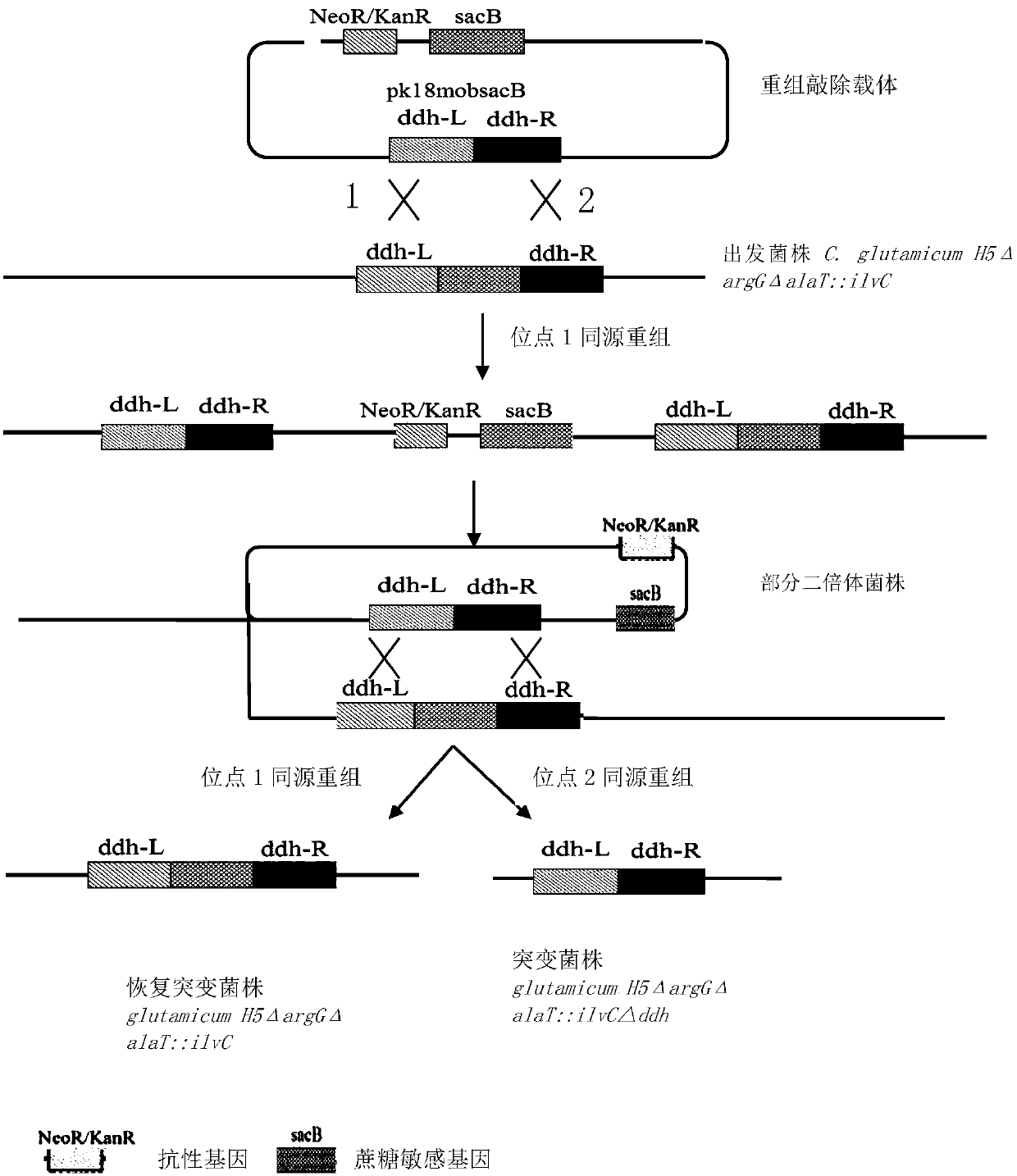

[0061] Example 2 Construction of recombinant strain C. glutamicum H5ΔargGΔalaT::ilvCΔddh

[0062] Transfer the correctly sequenced transformant in Example 1 to 5ml of LB medium, shake and culture at 37°C and 200rpm for 16 hours, take 5ml of the bacterial liquid, centrifuge at 10,000rpm for 2 minutes, discard the supernatant; use plasmid mini-extraction reagent for wet bacteria cassette to extract the plasmid. Electrotransfer the plasmid into the starting strain C. glutamicum H5ΔargGΔalaT::ilvC, spread the transformation product on LBHIS solid medium containing kanamycin sulfate, culture at 30°C for 48 hours until the transformant grows, select the transformant and transfer 3ml LB culture medium, shake culture at 30°C, 200rpm for 24h, spread the bacterial solution on a plate containing 10% sucrose, culture at 30°C for 48h until a single colony grows, pick a single colony and inoculate it on a plate containing kanamycin sulfate and On a plate containing 10% sucrose, select a si...

Embodiment 3

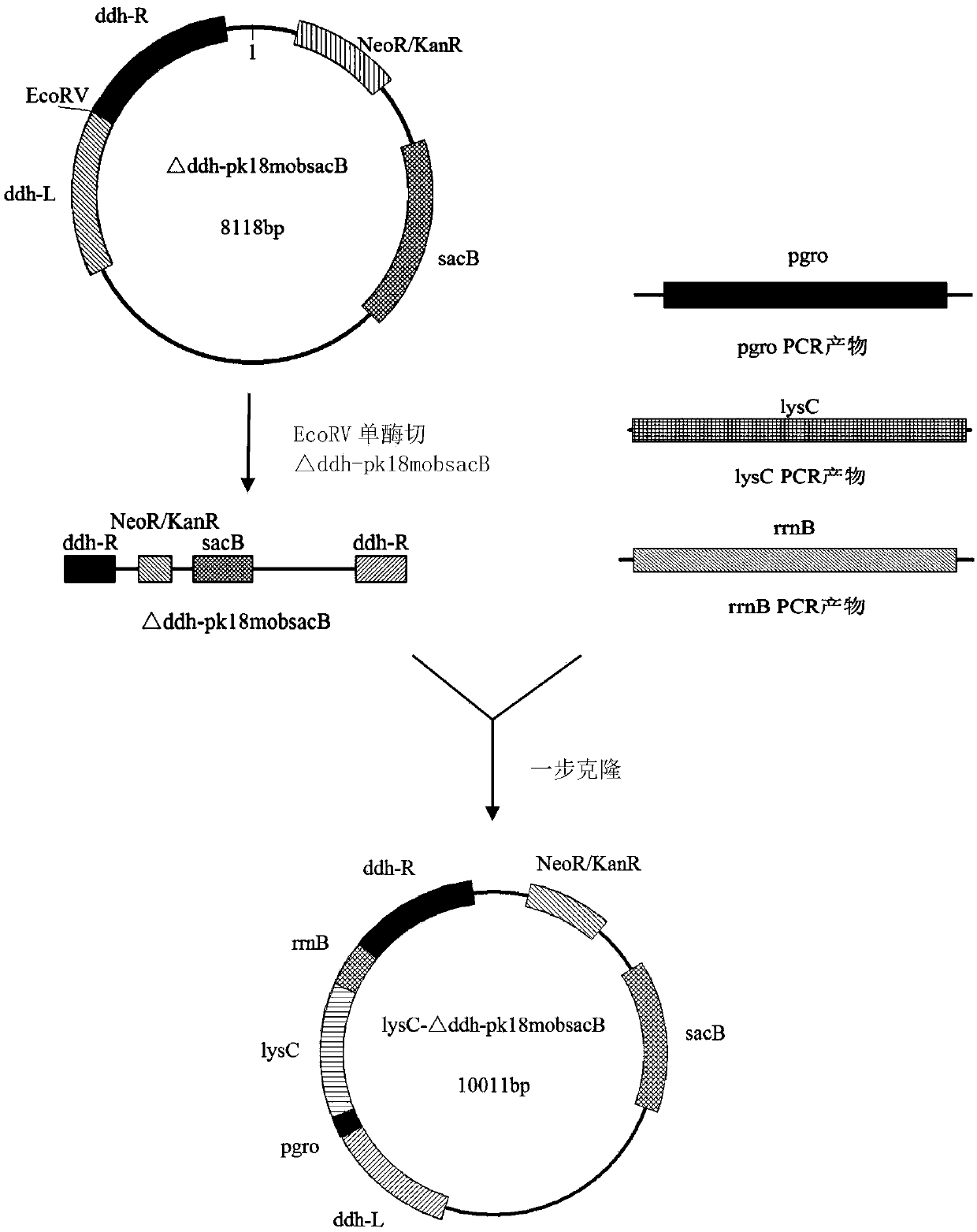

[0065] Example 3 Construction of lysC-Δddh-pk18mobsacB recombinant plasmid

[0066] The lysC-Δddh-pk18mobsacB recombinant plasmid was constructed, which contained the pgro promoter encoding the chaperone protein groES gene in the genome of the strain C. glutamicumH5ΔargGΔalaT::ilvC, the lysC gene encoding the aspartokinase, and the lysC gene from Escherichia coli- The rrnB terminator of the Corynebacterium glutamicum shuttle vector, the upstream and downstream fragments of the ddh gene encoding diaminopimelate dehydrogenase, and the transposable genes mob and sucrose that can effectively act on homologous recombination in Corynebacterium glutamicum Sensitive gene sacB, specific steps are as follows.

[0067] The vector Δddh-pk18mobsacB was digested with EcoR V, and the reaction system was: 1 μg of plasmid, 5 μl of 10×buffer, 1 μl of EcoR V, and 50 μl of water. Enzyme digestion at 37°C for 5h. 1% agarose gel electrophoresis detection and DNA gel recovery and purification kit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com