Mixed matrix anionic membrane and manufacturing method thereof

An anionic membrane and mixed matrix technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve problems such as limited bromination degree, achieve low swelling rate, increase free volume, and promote transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

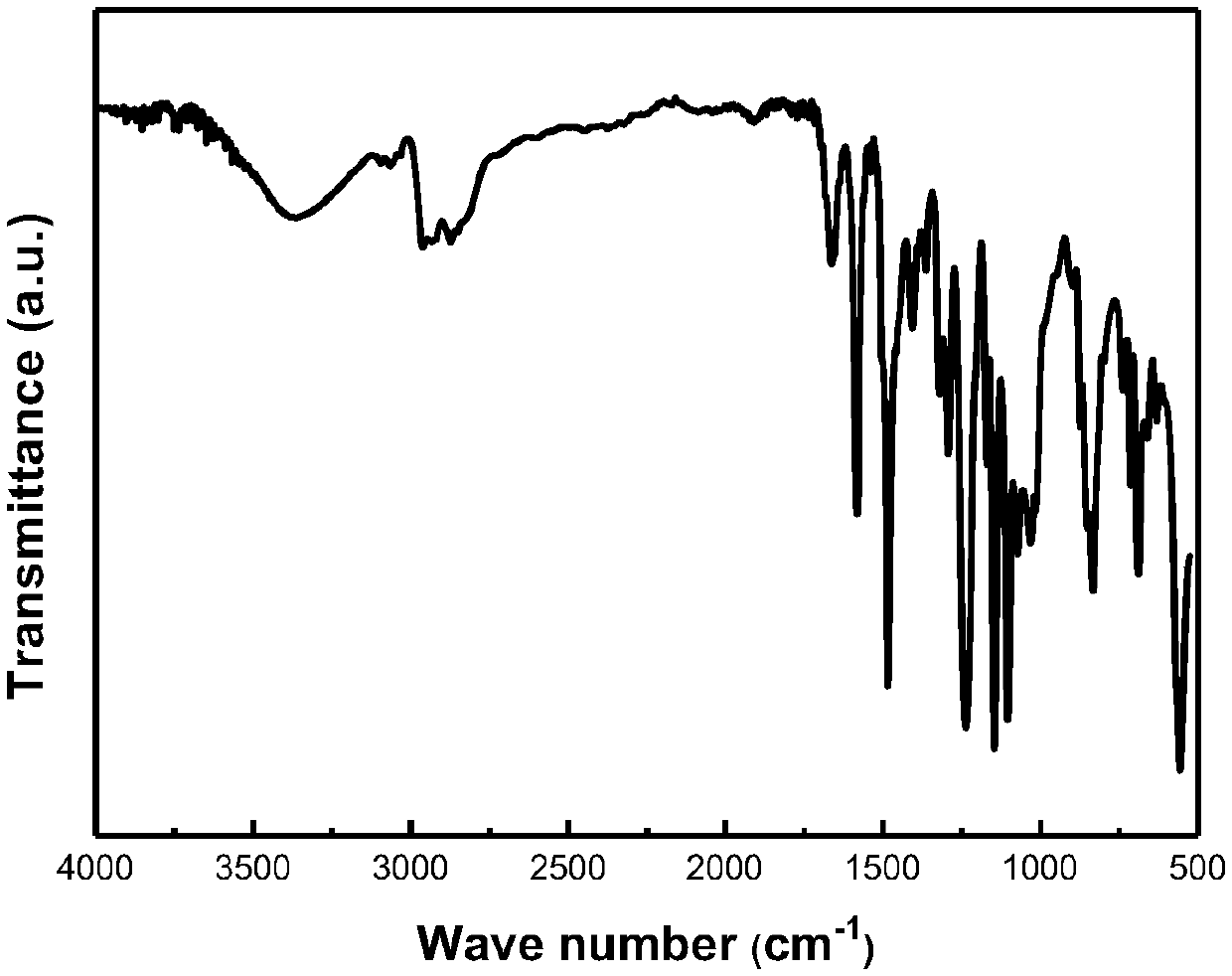

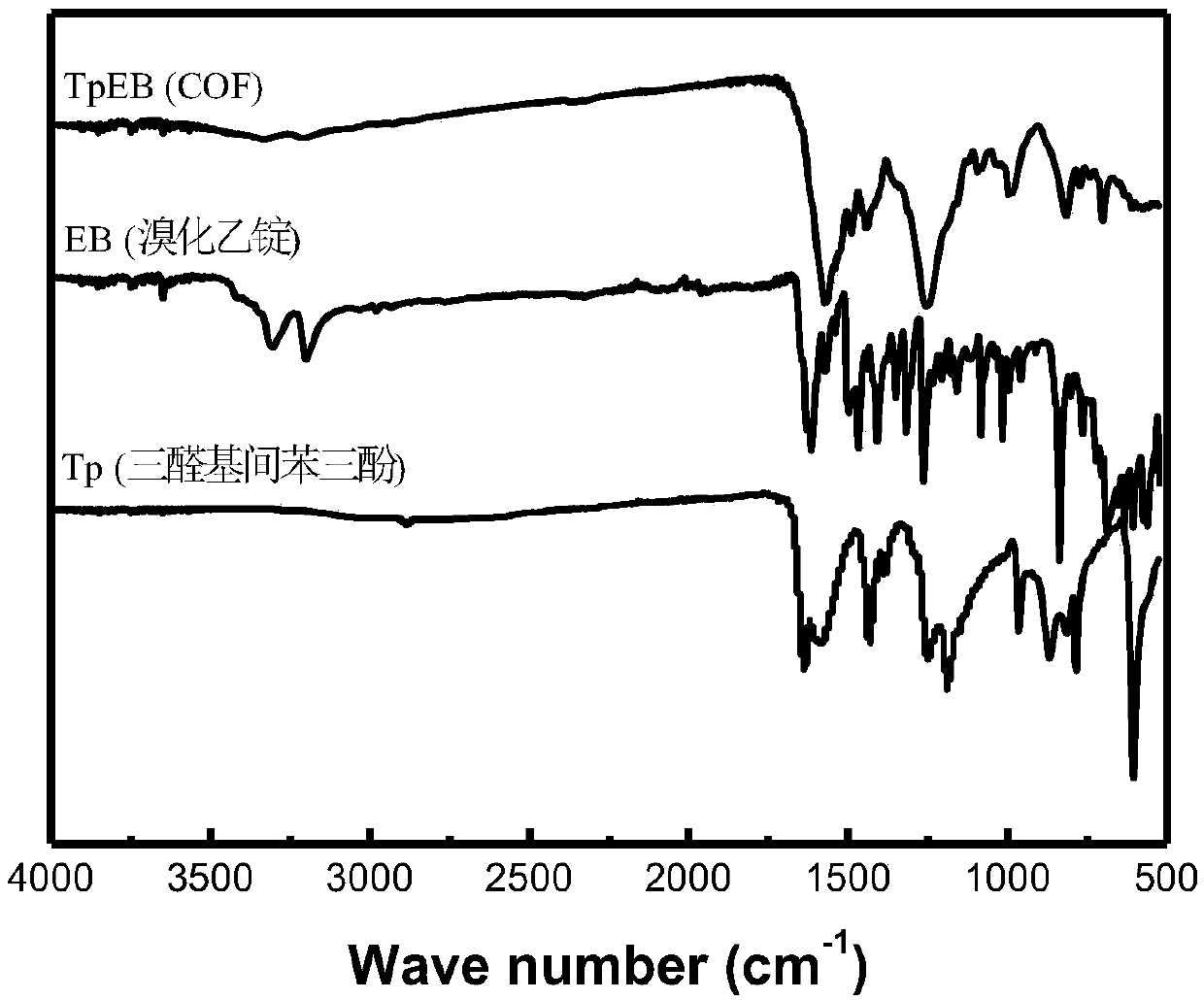

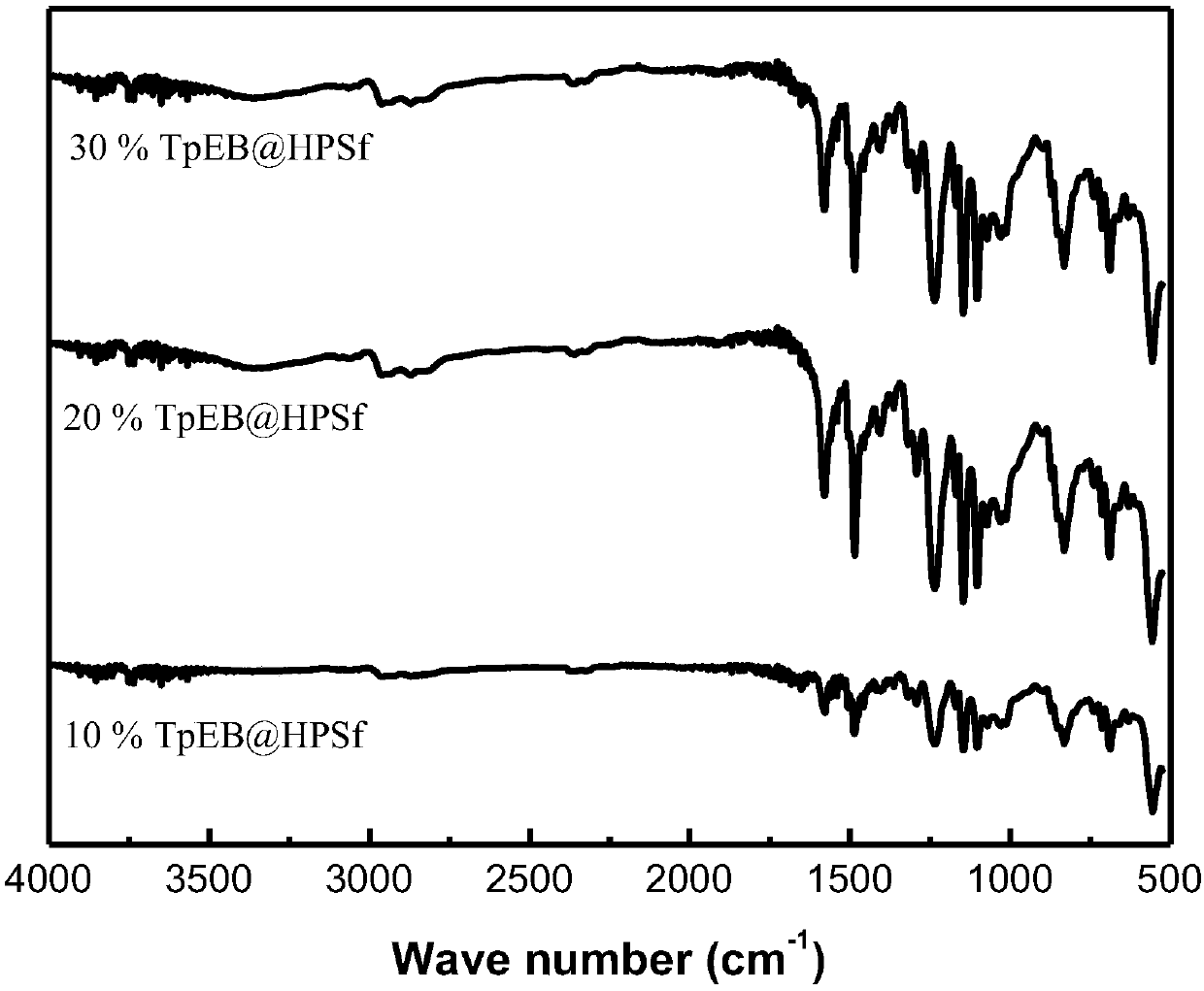

[0047] Hydrophilic modification of polyarylethersulfone: under nitrogen atmosphere, weigh 1g of chloromethylated polysulfone (DC=123%) material, dissolve it in 20mL of NMP, add 1.03g of diethanolamine, react at 80°C for 24h, and The reactant was poured into ethanol for precipitation, and after suction filtration and drying, the hydroxylated polyarylethersulfone HPSf was obtained (infrared spectrum, see figure 1 , a clear C-N peak appeared in the product, confirming that the alkylation reaction was successful).

[0048] Synthesis of 1,3,5-trialdehyde phloroglucinol: under nitrogen atmosphere, add 6.014g phloroglucinol, 15.098g urotropine and 90mL trifluoroacetic acid, react at 100°C for 2.25h, add 210mL of 3mol / L hydrochloric acid aqueous solution, continue to react for 0.75h. After it was cooled to room temperature, it was filtered with diatomaceous earth, and the filtrate was extracted with 350 mL of dichloromethane. The organic phase was dried over anhydrous magnesium sulfa...

Embodiment 2

[0053] Hydrophilic modification of polyarylethersulfone: under nitrogen atmosphere, weigh 1g of chloromethylated polysulfone (DC=123%) material, dissolve it in 10mL of NMP, add 1.03g of diethanolamine, react at 40°C for 48h, and The reactant was poured into ethanol to precipitate, and after suction filtration and drying, the hydroxylated polyarylethersulfone HPSf was obtained.

[0054] Synthesis of 1,3,5-trialdehyde phloroglucinol: under nitrogen atmosphere, add 5.594g phloroglucinol, 15.098g urotropine and 70mL trifluoroacetic acid, react at 120°C for 2h, add 234mL 3mol / L hydrochloric acid aqueous solution, continue to react for 0.5h. After it was cooled to room temperature, it was filtered with diatomaceous earth, and the filtrate was extracted with 350 mL of dichloromethane. The organic phase was dried over anhydrous sodium sulfate and rotary evaporated to obtain a yellowish powder, which was rinsed with an appropriate amount of hot ethanol and dried.

[0055] Synthesis of...

Embodiment 3

[0059] Hydrophilic modification of polyarylethersulfone: under nitrogen atmosphere, weigh 1.5g of chloromethylated polysulfone (DC=123%) material, dissolve it in 10mL of NMP, add 1.55g of diethanolamine, react at 100°C for 12h, Pour the reactant into ethanol to precipitate, and obtain hydroxylated polyarylethersulfone HPSf after suction filtration and drying.

[0060] Synthesis of 1,3,5-trialdehyde phloroglucinol: under nitrogen atmosphere, add 6.993g phloroglucinol, 15.098g urotropine and 105mL trifluoroacetic acid, react at 80°C for 2.5h, add 175mL of 3mol / L hydrochloric acid aqueous solution, continue to react for 1h. After it was cooled to room temperature, it was filtered with diatomaceous earth, and the filtrate was extracted with 350 mL of dichloromethane. The organic phase was dried over anhydrous magnesium sulfate and rotary evaporated to obtain a yellowish powder, which was rinsed with an appropriate amount of hot ethanol and dried.

[0061] Synthesis of TpEB covale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com