Quick-drying hydrophobic lacquer and preparation method thereof

A hydrophobic and bipyridine technology, applied in coatings, anti-corrosion coatings, natural resin coatings, etc., can solve the problems that hinder the road to industrialization, the drying speed of raw lacquer is slow, and the hydrophobic performance is general, so as to achieve fast drying speed, reduce time cost, The effect of good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

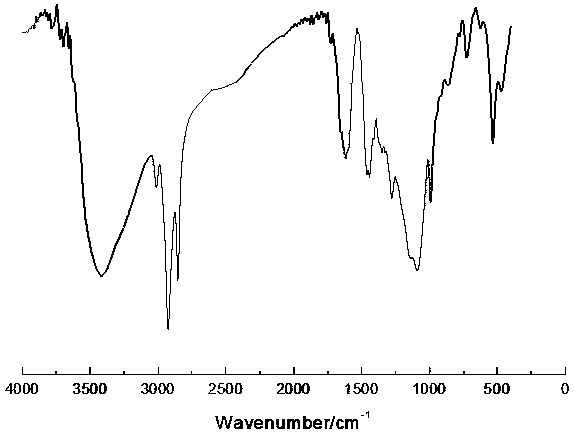

Image

Examples

Embodiment 1

[0021] Step (1) Preparation of aminated silica: use toluene as solvent, add nano-silica and (3-aminopropyl)triethoxysilane to heat and reflux for 24 hours, wash and dry to obtain aminated nano-silica silicon oxide.

[0022] Step (2) Reaction of 4-formaldehyde-2,2'-bipyridine with aminated nano-silica in toluene under reflux to obtain silica-loaded bipyridine. Afterwards, copper acetate was added to make it react to obtain a bipyridyl Cu(II) complex loaded with nano-silica.

[0023] Step (3) Add 1% bipyridine Cu(II) complex loaded with nano-silica to the raw lacquer, use toluene as solvent, stir for 0.5 h, adjust the humidity to 50%, and dry at room temperature to form a film.

Embodiment 2

[0025] Step (1) Preparation of aminated silica: use toluene as solvent, add nano-silica and 3-aminopropyldimethylmethoxysilane to heat and reflux for 24 hours, wash and dry to obtain aminated nano-silica silicon.

[0026] Step (2) Reaction of 4-formaldehyde-2,2'-bipyridine with aminated nano-silica in toluene under reflux to obtain silica-loaded bipyridine. Afterwards, copper chloride is added to make it react to obtain bipyridyl Cu(II) complex loaded with nano-silica.

[0027] Step (3) Add 5% bipyridyl Cu(II) complex loaded with nano-silica to the raw lacquer, use toluene as solvent, stir for 2 h, adjust the humidity to 75%, and dry at room temperature to form a film.

Embodiment 3

[0029] Step (1) Preparation of aminated silica: use toluene as solvent, add nano-silica and 3-aminopropyldimethylmethoxysilane to heat and reflux for 24 hours, wash and dry to obtain aminated nano-silica silicon.

[0030] Step (2) Reaction of 4-formaldehyde-2,2'-bipyridine with aminated nano-silica in toluene under reflux to obtain silica-loaded bipyridine. Afterwards, copper sulfate and copper are added to make it react to obtain bipyridyl Cu(II) complex loaded with nano-silica.

[0031] Step (3) Add 5% bipyridine Cu(II) complex loaded with nano-silica to the raw lacquer, use toluene as solvent, stir for 3 h, adjust the humidity to 75%, and dry at room temperature to form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com