Conductive aramid fiber, method for pretreating same and method for preparing conductive aramid fiber

Aramid fiber and pretreatment technology, applied in the direction of fiber treatment, fiber type, wear-resistant fiber, etc., can solve the problems of fiber performance degradation, fiber damage, environmental pollution, etc., achieve low cost, improve binding force, overcome fiber damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

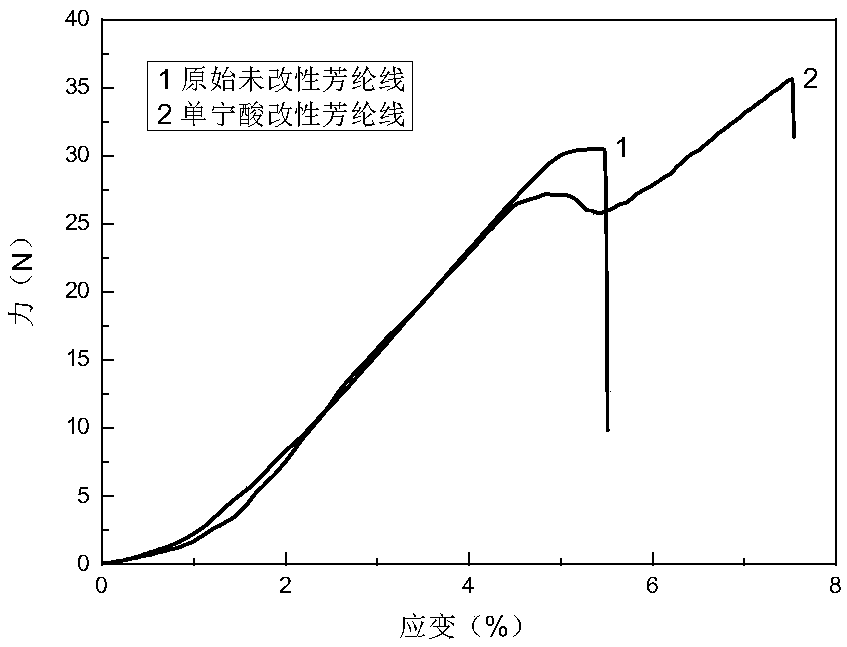

[0048] (1) Pretreat the aramid fiber thread with a tannic acid solution with a concentration of 2 g / L for 2 hours, take out the aramid fiber thread for washing, and dry to obtain a tannic acid modified aramid fiber thread;

[0049] (2) Soak the tannic acid-modified aramid fiber thread in 30g / L nickel sulfate hexahydrate solution for 1h, take it out, and obtain the aramid fiber thread that absorbs nickel ions;

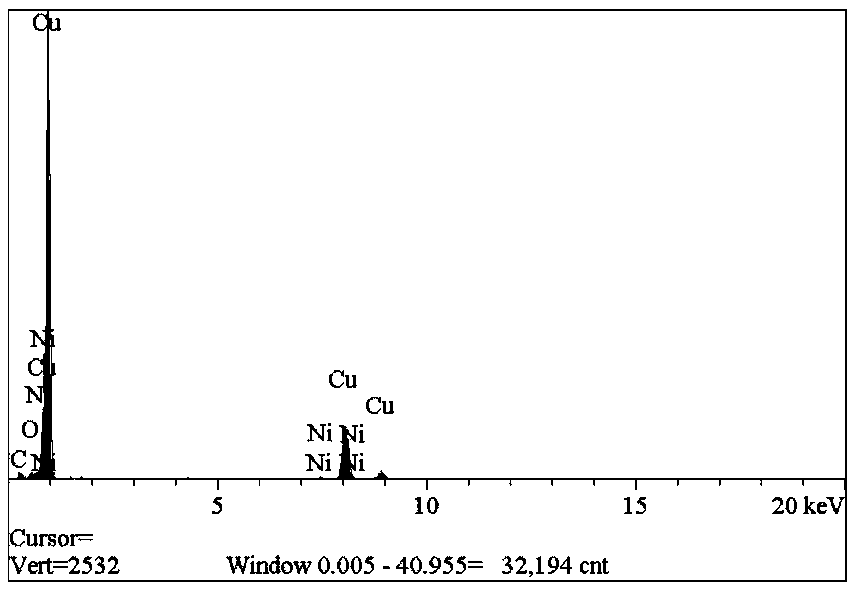

[0050] (3) Treat the aramid fiber thread adsorbed with nickel ions with 0.15 g / L potassium borohydride for 180 seconds to obtain the aramid fiber thread uniformly attached to the catalytic center of metallic nickel nanoparticles;

[0051] (4) Dissolve 4.0g copper sulfate pentahydrate, 0.5g nickel sulfate hexahydrate, 10g potassium sodium tartrate tetrahydrate, 2.0g sodium hydroxide, and 3.0g anhydrous sodium carbonate in 500ml deionized water, add 38% formaldehyde aqueous solution 3ml , to obtain the chemical plating solution;

[0052] (5) The aramid thread reduced by ...

Embodiment 2

[0055] (1) Pretreat the aramid yarn with a tannic acid solution with a concentration of 5g / L for 1.5h, take out the aramid yarn, wash it, and dry it to obtain a tannic acid modified aramid yarn;

[0056] (2) Soak the tannic acid modified aramid fiber thread in 20g / L nickel sulfate hexahydrate solution for 30min, take it out, and obtain the aramid fiber thread that absorbs nickel ions;

[0057] (3) Treat the aramid fiber thread adsorbed with nickel ions with 0.60g / L potassium borohydride solution for 60s to obtain the aramid fiber thread uniformly attached to the catalytic center of metallic nickel nanoparticles;

[0058] (4) Dissolve 3.0g copper sulfate pentahydrate, 1.0g nickel sulfate hexahydrate, 15g sodium potassium tartrate tetrahydrate, 5.0g sodium hydroxide, and 2.0g anhydrous sodium carbonate in 500ml deionized water, add 5ml of 38% formaldehyde solution , to obtain the chemical plating solution;

[0059] (5) The aramid wire reduced by potassium borohydride was soaked...

Embodiment 3

[0061] (1) Pretreat the aramid fiber thread with a tannic acid solution with a concentration of 10 g / L for 1 hour, take out the aramid fiber thread for washing, and dry to obtain a tannic acid modified aramid fiber thread;

[0062] (2) Soak the tannic acid modified aramid thread in 40g / L nickel sulfate hexahydrate solution for 1h, take it out, and obtain the aramid thread that absorbs nickel ions;

[0063] (3) Treat the aramid fiber thread adsorbed with nickel ions with 0.45g / L potassium borohydride solution for 300s to obtain the aramid fiber thread evenly attached to the catalytic center of metallic nickel nanoparticles;

[0064] (4) Dissolve 5.0g copper sulfate pentahydrate, 2.0g nickel sulfate hexahydrate, 20g potassium sodium tartrate tetrahydrate, 4.0g sodium hydroxide, and 1.0g anhydrous sodium carbonate in 500ml deionized water, add 4ml of 38% formaldehyde solution , to obtain the chemical plating solution;

[0065] (5) The aramid wire reduced by potassium borohydride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com