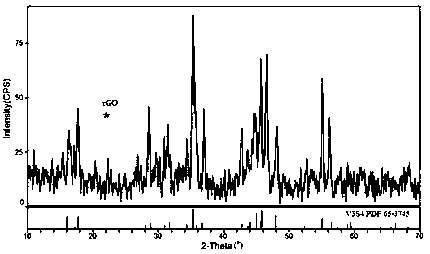

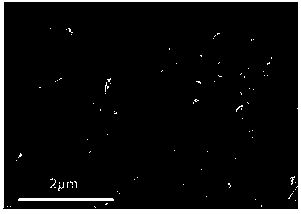

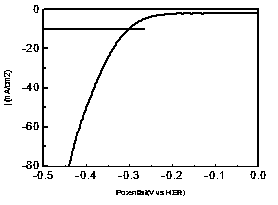

Preparation of V3S4@rGO and application of electro-catalytic property thereof

An electrocatalyst and oxide stone technology, applied in physical/chemical process catalysts, electrodes, electrolysis processes, etc., can solve problems such as economic cost constraints, and achieve the effects of simple process, uniform chemical composition, high purity and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Weigh 50 mg of graphene oxide and disperse it in 100 mL of deionized water, and sonicate for 5 hours to obtain a 0.5 mg / mL graphene oxide dispersion.

[0023] Step 2: Mix 4mmol of oxalic acid, 2mmol of V 2 o 5 Dissolve in 35 mL of deionized water, add 5 mL of the above graphene oxide dispersion, and stir magnetically for 1 h to obtain a mixed solution.

[0024] Step 3: Pour the prepared solution into the reaction polytetrafluoroethylene lining. The filling ratio of the reaction kettle is 80%, and put the lining into the outer kettle. After fixing it, place it in the oven. The reaction conditions Insulate at 180°C for 24h.

[0025] Step 4: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction liquid is poured out and washed 3 times with deionized water and absolute ethanol respectively. After suction filtration, the samples were collected and dried under vacuum at 60° C. for 24 hours to ...

Embodiment 2

[0031] Step 1: Weigh 50 mg of graphene oxide and disperse it in 100 mL of deionized water, and sonicate for 5 hours to obtain a 0.5 mg / mL graphene oxide dispersion.

[0032] Step 2: Mix 5mmol of oxalic acid, 2mmol of V 2 o 5 Dissolve in 30 mL of deionized water, add 10 mL of the above graphene oxide dispersion, and stir magnetically for 1 h to obtain a mixed solution.

[0033] Step 3: Pour the prepared solution into the reaction polytetrafluoroethylene lining. The filling ratio of the reaction kettle is 80%, and put the lining into the outer kettle. After fixing it, place it in the oven. The reaction conditions Insulate at 200°C for 20h.

[0034] Step 4: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction liquid is poured out and washed 3 times with deionized water and absolute ethanol respectively. After suction filtration, the samples were collected and dried under vacuum at 80° C. for 12 hours to...

Embodiment 3

[0039] Step 1: Weigh 50 mg of graphene oxide and disperse it in 100 mL of deionized water, and sonicate for 5 hours to obtain a 0.5 mg / mL graphene oxide dispersion.

[0040]Step 2: Mix 5mmol of oxalic acid, 2mmol of V 2 o 5 Dissolve in 20 mL of ethylene glycol, add 20 mL of the above graphene oxide dispersion, and stir magnetically for 1 h to obtain a mixed solution.

[0041] Step 3: Pour the prepared solution into the reaction polytetrafluoroethylene lining. The filling ratio of the reaction kettle is 80%, and put the lining into the outer kettle. After fixing it, place it in the oven. The reaction conditions Insulate at 180°C for 24h.

[0042] Step 4: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction liquid is poured out and washed 3 times with deionized water and absolute ethanol respectively. After suction filtration, the samples were collected and dried under vacuum at 40° C. for 24 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com