Method for producing light calcium carbonate and magnesium sulfate heptahydrate from salty mud

A technology of light calcium carbonate and magnesium sulfate heptahydrate, applied in the direction of magnesium sulfate, calcium carbonate/strontium/barium, chemical instruments and methods, etc., can solve the problem of high cost of hydrochloric acid and sodium hydroxide, large water volume and large energy consumption of pyrolysis , low solubility of magnesium bicarbonate, etc., to achieve the effect of accelerating the carbonization reaction rate, reducing water consumption, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

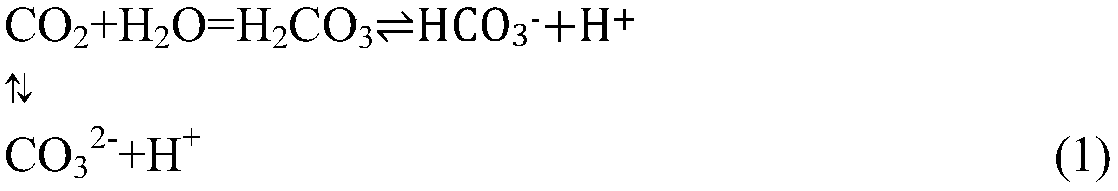

Method used

Image

Examples

Embodiment 1

[0044] A kind of salt mud produces the method for light calcium carbonate and magnesium sulfate heptahydrate, comprises the following steps:

[0045] Step A: Add calcium sulfate with a ratio of 1:1.05 to the amount of magnesium hydroxide contained in salt mud to a certain quality of salt mud, put it in a 500ml beaker, add water to make a total volume of 400ml, and a solid-to-liquid ratio of 1 :4 Serum.

[0046] Step B: Into the slurry obtained in step A, feed 60ml / min pure carbon dioxide at a temperature of 40°C for carbonization for 60min, calcium sulfate is converted into calcium carbonate, magnesium hydroxide is converted into soluble magnesium sulfate, and the separation of calcium and magnesium is achieved by filtration.

[0047] Step C: Dry the filter cake obtained in Step B at 110°C for 10 hours, and then pulverize it to obtain a light calcium carbonate product

[0048] Step D: the filtrate obtained in step B is concentrated at 100°C, crystallized by cooling, and dried...

Embodiment 2

[0050] 4. A method for producing light calcium carbonate and magnesium sulfate heptahydrate from salt mud, comprising the following steps:

[0051]Step A: Add calcium sulfate with a ratio of 1:1 to the amount of magnesium hydroxide contained in salt mud to a certain quality of salt mud, put it in a 500ml beaker, add water to make a total volume of 400ml, and a solid-to-liquid ratio of 1 :15 Serum.

[0052] Step B: Into the slurry obtained in step A, feed 40ml / min pure carbon dioxide at a temperature of 60°C for carbonization for 20min, calcium sulfate is converted into calcium carbonate, magnesium hydroxide is converted into soluble magnesium sulfate, and the separation of calcium and magnesium is achieved by filtration.

[0053] Step C: Dry the filter cake obtained in Step B at 110°C for 6 hours, and then pulverize it to obtain a light calcium carbonate product.

[0054] Step D: the filtrate obtained in step B is concentrated at 105°C, crystallized by cooling, and dried to o...

Embodiment 3

[0056] A kind of salt mud produces the method for light calcium carbonate and magnesium sulfate heptahydrate, comprises the following steps:

[0057] Step A: Add calcium sulfate with a ratio of 1:0.95 to the amount of magnesium hydroxide contained in salt mud to a certain quality of salt mud, put it in a 500ml beaker, add water to make a total volume of 400ml, and a solid-to-liquid ratio of 1 :10 Serum.

[0058] Step B: Introduce 60 ml / min of flue gas with a carbon dioxide volume fraction greater than 10% into the slurry obtained in step A, carbonize for 120 min at a temperature of 20° C., convert calcium sulfate into calcium carbonate, and convert magnesium hydroxide into soluble magnesium sulfate. Filtration realizes the separation of calcium and magnesium.

[0059] Step C: Dry the filter cake obtained in Step B at 110°C for 8 hours, and then pulverize it to obtain a light calcium carbonate product

[0060] Step D: the filtrate obtained in step B is concentrated at 110°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com