Chicken manure fermented biological organic fertilizer and preparation method thereof

A technology for fermenting organisms and organic fertilizers, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, and organic fertilizers, can solve the problems of high cost, reduction of chemical fertilizers, and high energy consumption, and achieve the effect of preventing erosion and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

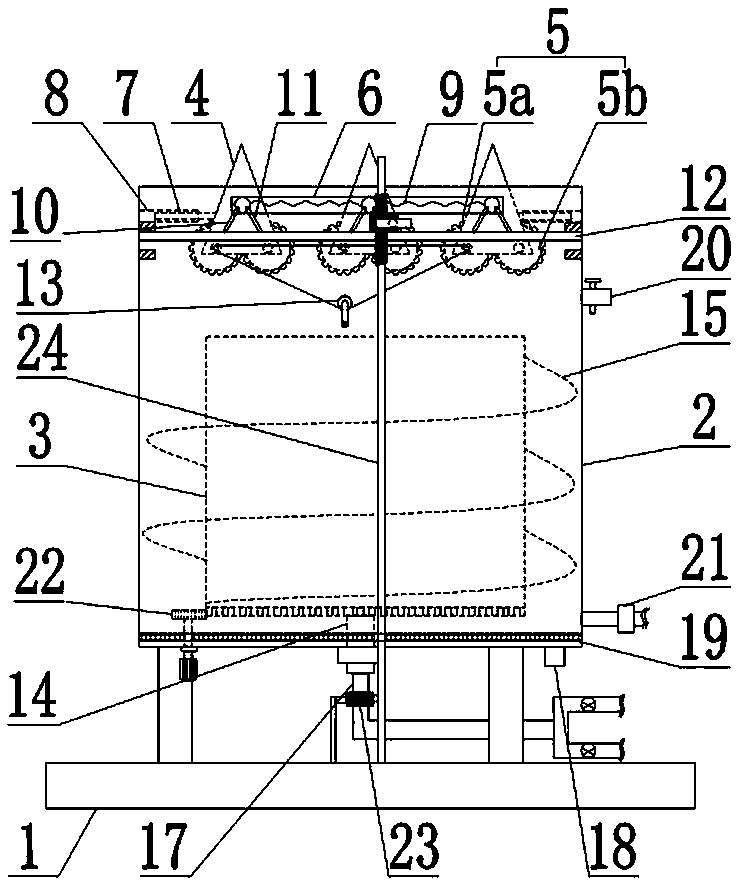

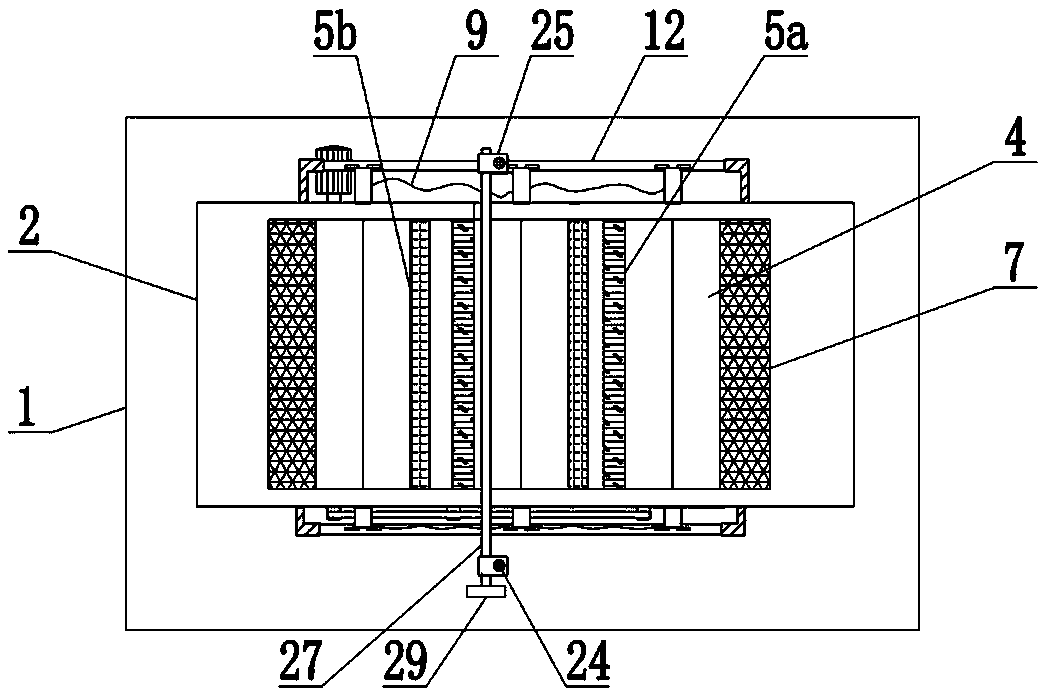

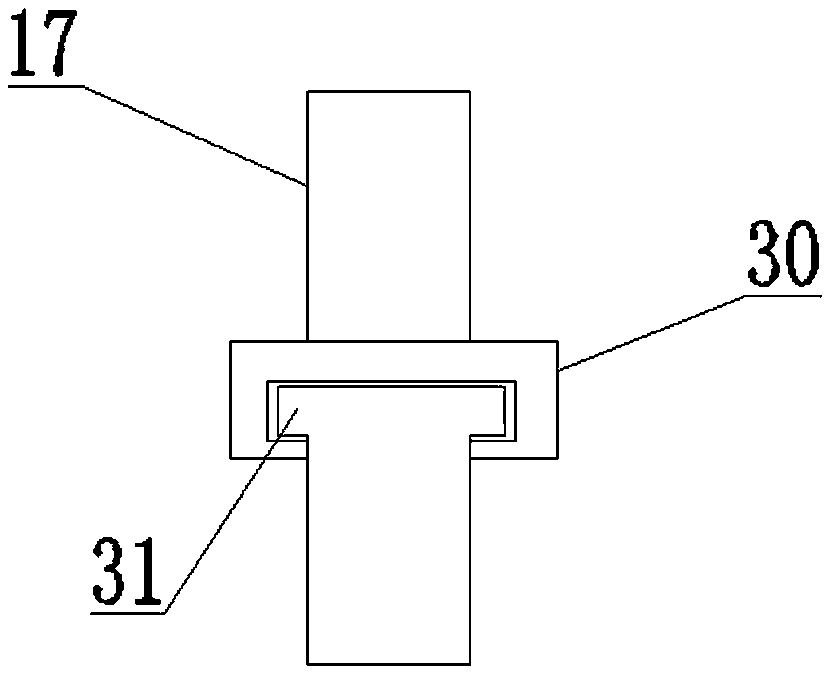

Method used

Image

Examples

Embodiment 1

[0055] A kind of chicken manure fermented biological organic fertilizer, including the following components by weight:

[0056] Chicken manure: 150 servings;

[0057] Shrimp shell: 27 servings;

[0058] Crab shell: 29 servings;

[0059] Fermentation material: 100 servings;

[0060] Wormwood ash: 30 parts;

[0061] Compound bacterial agent: 25 parts;

[0062] Honey locust branches and leaves: 40 parts;

[0063] Deodorant: 15 parts;

[0064] The preparation method of the chicken manure fermented biological organic fertilizer includes the following steps:

[0065] Step 1. Material pretreatment: Put the shrimp shells and crab shells into a pulverizer and pulverize to obtain mixed shell powder; then put the fermentation base material and honey locust branches and leaves into the pulverizer to pulverize to obtain fermentation base material powder Slag

[0066] Step 2. Anaerobic fermentation: Put the fermentation bottom material powder and chicken manure prepared in Step 1 into the fermentation tan...

Embodiment 2

[0077] The difference between the second embodiment and the first embodiment is:

[0078] A kind of chicken manure fermented biological organic fertilizer, including the following components by weight:

[0079] Chicken manure: 185 parts;

[0080] Shrimp shell: 24 servings;

[0081] Crab shell: 25 servings;

[0082] Fermentation material: 120 servings;

[0083] Wormwood ash: 40 parts;

[0084] Compound bacterial agent: 18 parts;

[0085] Honey locust branches and leaves: 47 parts;

[0086] Deodorant: 12 parts;

[0087] In this embodiment, the water content of the material in the second step is 55%, and the anaerobic fermentation is carried out for 4 days, during which the temperature in the fermentation tank is maintained at 40°C;

[0088] In this embodiment, the temperature in the fermentation tank in the step 3 is raised to 65°C, and the aerobic fermentation is performed for 4 days;

[0089] In this embodiment, the temperature in the fermentation tank in the step 4 is reduced to 20°C, and the...

Embodiment 3

[0092] The third embodiment is different from the first embodiment in:

[0093] A kind of chicken manure fermented biological organic fertilizer, including the following components by weight:

[0094] Chicken manure: 200 servings;

[0095] Shrimp shell: 20 servings;

[0096] Crab shell: 32 servings;

[0097] Fermentation material: 80 parts;

[0098] Wormwood ash: 55 parts;

[0099] Compound bacterial agent: 29 parts;

[0100] Honey locust branches and leaves: 55 parts;

[0101] Deodorant: 18 parts;

[0102] In this embodiment, the water content of the material in the second step is 50%, and the anaerobic fermentation is carried out for 3 days, during which the temperature in the fermentation tank is maintained at 40°C;

[0103] In this embodiment, the temperature in the fermentation tank in the third step is raised to 47°C, and the aerobic fermentation is performed for 3 days;

[0104] In this embodiment, in the step 4, the temperature in the fermentation tank is reduced to 24°C, and the ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com