Polyester film without anti-blocking agent and preparation method of polyester film

A polyester film, no opening technology, applied in the production of bulk chemicals, etc., can solve the problems of increased manufacturing costs, large interface differences, phase separation, etc., to achieve the effect of improving the movement ability and meeting the requirements of winding and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

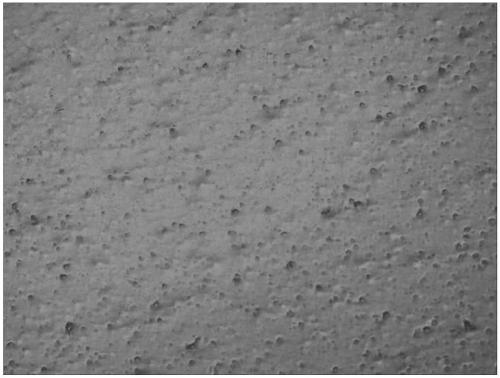

Image

Examples

Embodiment 1

[0055] A kind of preparation method of non-blocking agent polyester film, the steps are:

[0056] The polyethylene terephthalate raw material is pre-crystallized at a temperature of 165°C—after drying, it is mixed uniformly and transported to an extruder, melted at a temperature of 280°C, passed through a filter, and released from a single-layer or multi-layer mold Extruded in flakes from the head. One side of the extruded melt is attached to a 20° C. cold drum (chill roll) by an electrostatic adsorption device for cooling, and the other side is cooled by back cold air to obtain a polyester sheet.

[0057] Above-mentioned polyester sheet material is placed in the airtight container of carbon dioxide supercritical body (pressure is 20MPa and temperature is 32 ℃) and soaks 25min, is placed in the organic solution that temperature is 100 ℃ after taking out (the solvent of organic solution is water, and solute is The mass ratio of sodium benzoate to 4,4'-sodium biphenyldicarboxyl...

Embodiment 2

[0059] A kind of preparation method of non-blocking agent polyester film, the steps are:

[0060] The polyethylene terephthalate raw material is pre-crystallized at a temperature of 170°C—after drying, it is mixed uniformly and transported to an extruder, melted at a temperature of 282°C, and passed through a filter from a single-layer or multi-layer mold Extruded in flakes from the head. One side of the extruded melt is attached to a 25° C. cold drum (chill roll) by an electrostatic adsorption device for cooling, and the other side is cooled by back cold air to obtain a polyester sheet.

[0061] Above-mentioned polyester sheet material is placed in the airtight container of carbon dioxide supercritical body (pressure is 20MPa and temperature is 35 ℃) and soaks 10min, is placed in the organic solution that temperature is 100 ℃ after taking out (the solvent of organic solution is water; Solute is The mass ratio of sodium benzoate to 4,4'-sodium biphenyldicarboxylate is 2:1; th...

Embodiment 3

[0063] A method for preparing a polyester film without an anti-blocking agent. The "organic solution at a temperature of 100°C after taking out" described in Example 2 is replaced with "an organic solution at a temperature of 80°C after taking out", and other Same as embodiment 2, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| optical clarity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com