Phosphorus-containing flame-retardant thermoplastic polyurethane, solid electrolyte and lithium battery

A technology of thermoplastic polyurethane and solid electrolyte, which is applied in the field of lithium batteries, can solve the problems of high brittleness of the electrolyte membrane, damage to the environment and construction personnel, and low ion conductivity of the solid polymer electrolyte, and achieve excellent mechanical properties and heat resistance and flame retardancy , solve the problem of flammability, the effect of excellent ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

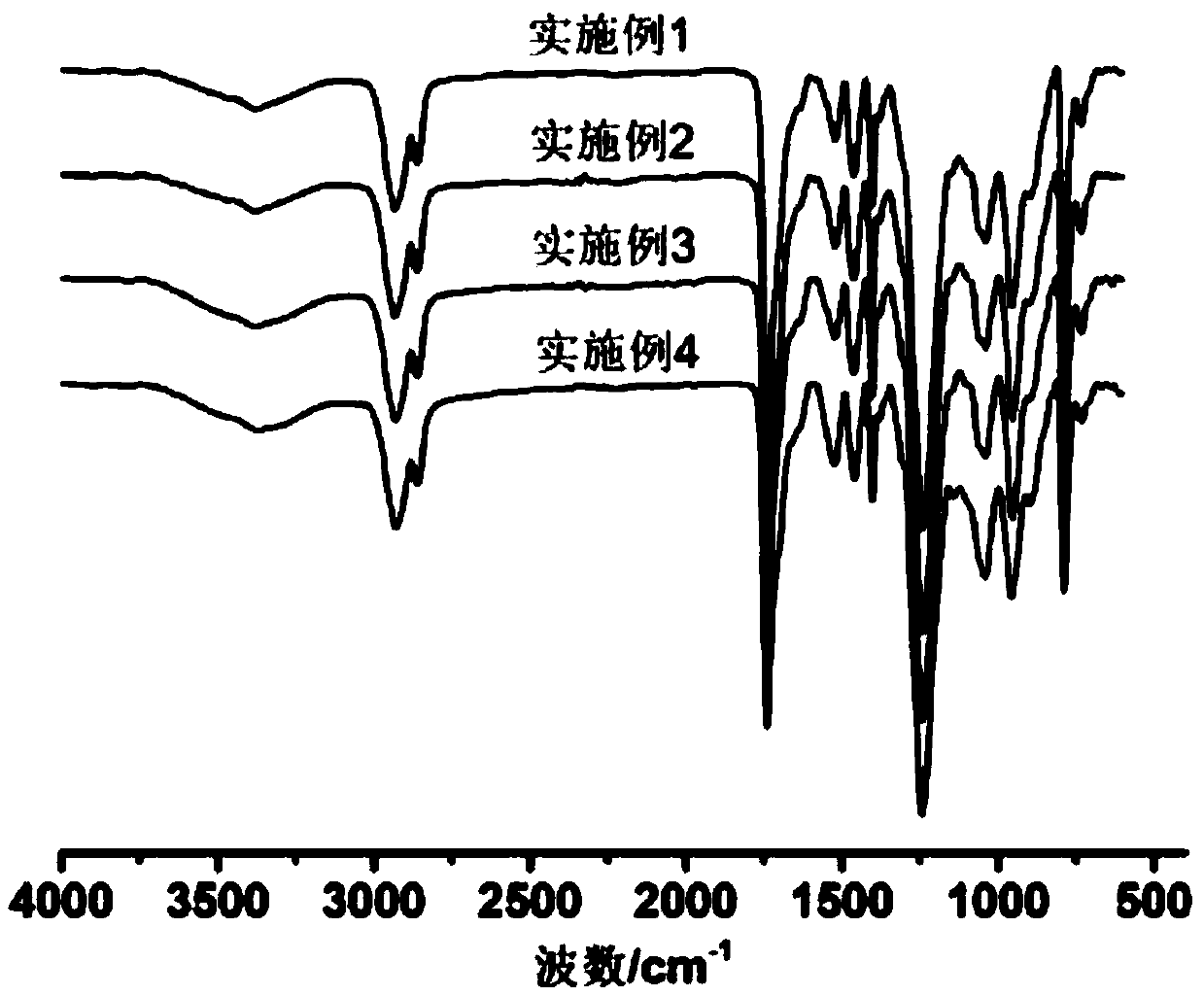

Image

Examples

Embodiment 1

[0026] A flame-retardant polyurethane solid-state electrolyte comprises 70% by weight of phosphorus-containing flame-retardant thermoplastic polyurethane and 30% by weight of lithium bistrifluoromethanesulfonylimide. When the flame-retardant polyurethane solid electrolyte is prepared into an electrolyte membrane, it includes: dissolving the above-mentioned phosphorus-containing flame-retardant thermoplastic polyurethane and lithium bistrifluoromethanesulfonylimide in DMF according to the above weight percentage, and mechanically stirring to obtain a casting solution. Pour the casting solution into the groove of the polytetrafluoroethylene plate, dry at 30°C for 2 days, and then put it in a vacuum drying oven at 60°C for 2 days to form a film, and obtain a flame-retardant polyurethane solid electrolyte membrane.

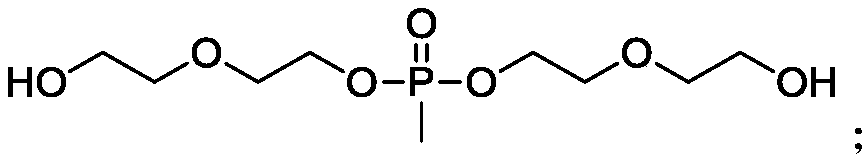

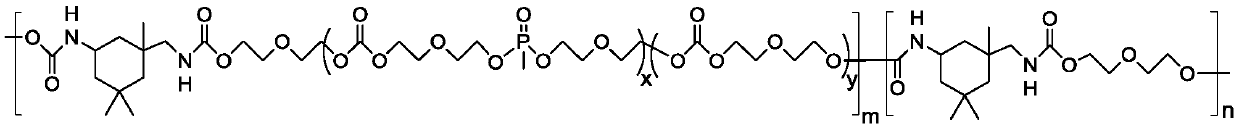

[0027] The above-mentioned phosphorus-containing flame-retardant thermoplastic polyurethane has a structural formula of:

[0028]

[0029]The method for preparing...

Embodiment 2

[0033] A flame-retardant polyurethane solid-state electrolyte comprises 70% by weight of phosphorus-containing flame-retardant thermoplastic polyurethane and 30% by weight of lithium bistrifluoromethanesulfonylimide. When the flame-retardant polyurethane solid electrolyte is prepared into an electrolyte membrane, it includes: dissolving the above-mentioned phosphorus-containing flame-retardant thermoplastic polyurethane and lithium bistrifluoromethanesulfonylimide in DMF according to the above weight percentage, and mechanically stirring to obtain a casting solution. The casting solution is formed into a film to obtain a flame-retardant polyurethane solid electrolyte membrane.

[0034] The above-mentioned phosphorus-containing flame-retardant thermoplastic polyurethane has a structural formula of:

[0035]

[0036] The method for preparing the phosphorus-containing flame-retardant thermoplastic polyurethane includes: mixing 25wt% isophorone diisocyanate and 70wt% phosphorus...

Embodiment 3

[0040] A flame-retardant polyurethane solid-state electrolyte comprises 70% by weight of phosphorus-containing flame-retardant thermoplastic polyurethane and 30% by weight of lithium bistrifluoromethanesulfonylimide. When the flame-retardant polyurethane solid electrolyte is prepared into an electrolyte membrane, it includes: dissolving the above-mentioned phosphorus-containing flame-retardant thermoplastic polyurethane and lithium bistrifluoromethanesulfonylimide in DMF according to the above weight percentage, and mechanically stirring to obtain a casting solution. The casting solution is formed into a film to obtain a flame-retardant polyurethane solid electrolyte membrane.

[0041] The above-mentioned phosphorus-containing flame-retardant thermoplastic polyurethane has a structural formula of:

[0042]

[0043] The method for preparing the phosphorus-containing flame-retardant thermoplastic polyurethane includes: mixing 25wt% isophorone diisocyanate and 70wt% phosphorus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com