Antifouling modified walnut shell filter material as well as preparation method and application thereof

A walnut shell and filter material technology, which is applied in the field of antifouling modified walnut shell filter material and its preparation, can solve the problems of material running, poor backwash effect, filter damage, etc., achieve simple equipment and process, and improve dispersion effect , the effect of not easy oil stain adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

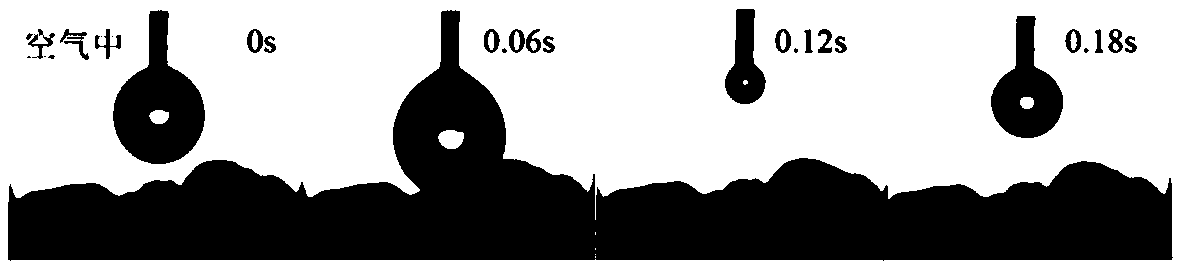

[0022] (1) At room temperature, wash the walnut shell filter material with clean water 3 times to remove surface dust and impurities, and dry for later use; (2) Respectively 0.5g of SiO with a particle size of 10-40nm and 1μm 2 Nano particles and 0.5g KH-550 are dispersed in 40g water and stirred to form a uniform mixed solution; (3) 0.5g water-based fluorocarbon resin, 0.5g water-based epoxy resin and 0.5mg tripolyphosphoric acid are added to the above-mentioned mixed solution. 0.5mg polyvinyl alcohol, mix well to obtain the required modification solution; (4) Add 20g of the washed walnut shell filter material to the obtained modification solution, and after mechanical stirring for 2h at 800r / min The modified walnut shell filter material can be obtained by drying for 8 hours at 60°C. figure 1 In order to modify the super-hydrophilic process of the walnut shell in the air, it can be seen from the figure that the water droplets spread out as soon as they touch the surface of the w...

Embodiment 2

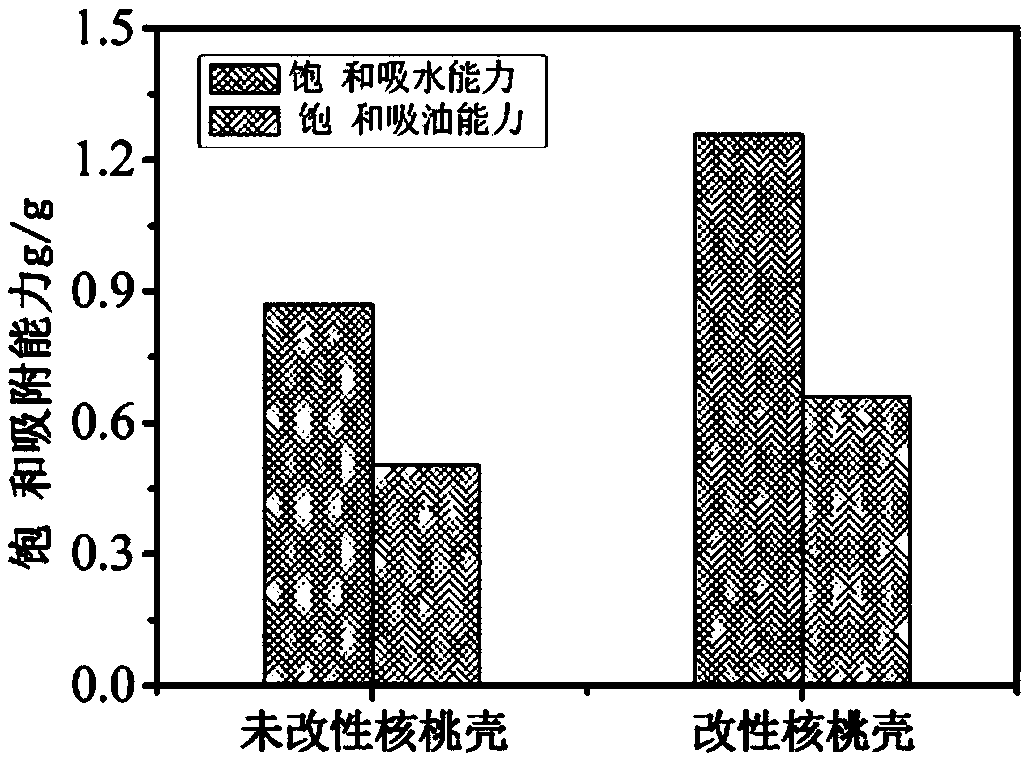

[0024] (1) At room temperature, scrub the walnut shell filter material with water for 5 times to remove surface dust and impurities, and dry for later use; (2) Respectively add 1g of SiO with a particle size of 10-40nm and 1μm 2 Disperse nanoparticles and 1g KH-570 in 60g water, stir them to form a uniform mixed solution; (3) Add 1g water-based acrylic resin, 1g water-based polyvinyl alcohol resin, 0.5mg tripolyphosphoric acid, 0.5mg polypropylene to the above-mentioned mixed solution After mixing, the required modification solution is obtained; (4) 30g of the washed walnut shell filter material is added to the obtained modification solution, and it is mechanically stirred for 2h at a speed of 600r / min and then placed at 80℃ After drying for 5 hours, the modified walnut shell filter material can be obtained. Figure 4 Scanning electron micrograph of modified walnut shell surface morphology. It can be seen from the figure that the surface is coated with resin and SiO 2 The partic...

Embodiment 3

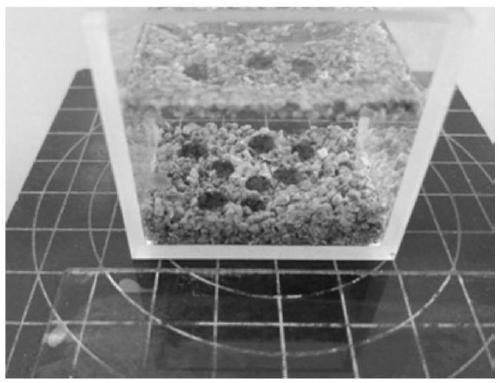

[0026] (1) At room temperature, wash the walnut shell filter material with clean water 5 times to remove surface dust and impurities, and dry for later use; (2) Respectively 1g of TiO with a particle size of 100-200nm and 1μm 2 Nanoparticles and 2g KH-570 are dispersed in 60g water and stirred to form a uniform mixed solution; (3) Add 1g water-based polyurethane resin, 1g water-based fluorosilicone resin, 0.5mg sodium pyrophosphate, 0.5mg polyacrylamide to the above-mentioned mixed solution After mixing, the required modification solution is obtained; (4) 40g of washed walnut shell filter material is added to the obtained modification solution, stirred at 600r / min for 2h, and dried at 60℃ for 5h , The modified walnut shell filter material can be obtained. Oilfield oily sewage treatment equipment such as Figure 5 As shown in (a), the inner diameter of the glass tube is 3cm, and the filling height of the filter material is 5cm. The device is used to filter 0.5L of oily sewage, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com