Hollow ferroferric oxide microsphere@polyaniline/polyimide composite film wave-absorbing material and preparation method thereof

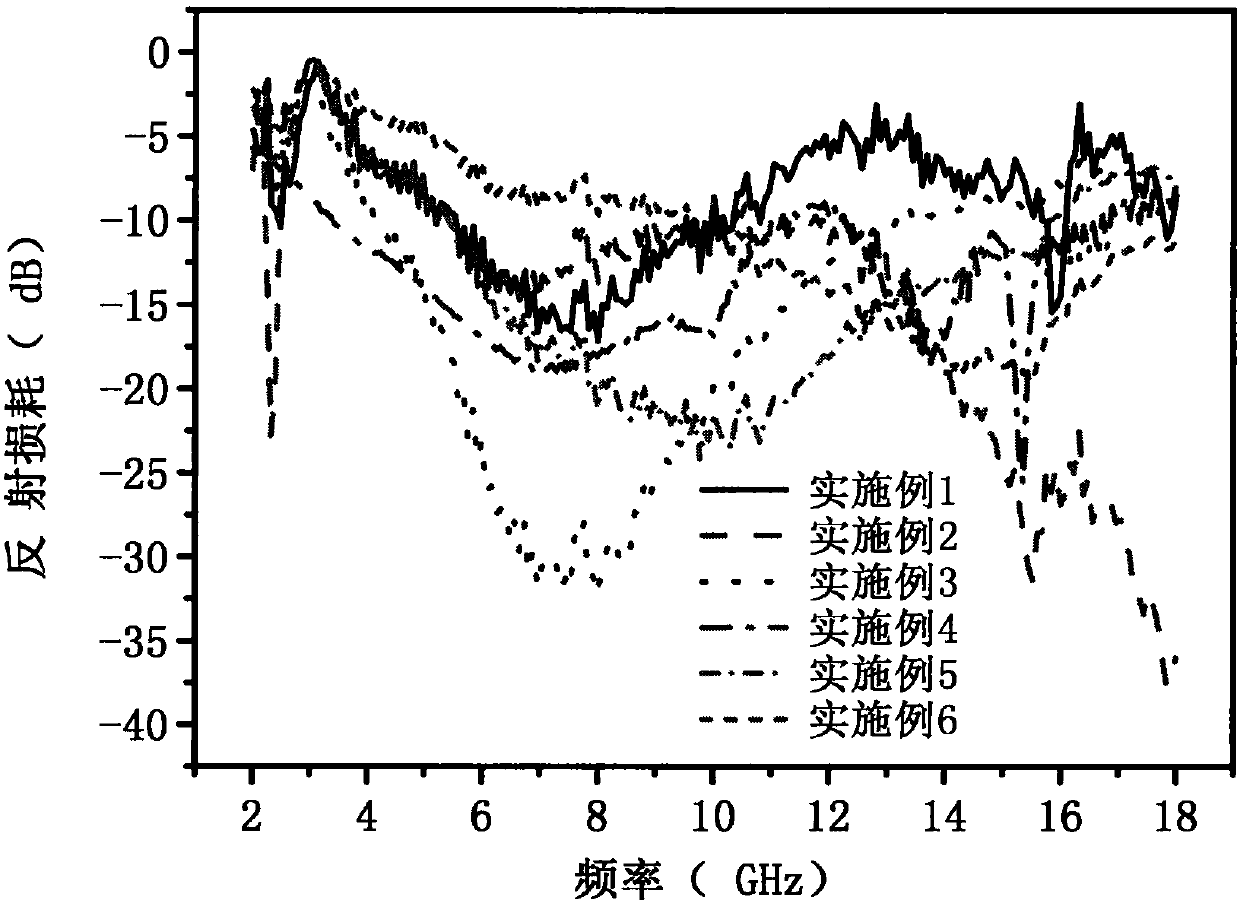

A technology of ferric oxide and composite film, which is applied in the field of hollow ferric oxide microsphere@polyaniline/polyimide composite film absorbing material and preparation, which can solve the problem of high complex permittivity and difficulty in meeting impedance matching. , thin thickness, light weight, impedance mismatch, etc., to increase the probability of reflection and refraction, reduce phase separation, and improve absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of hollow ferroferric oxide microsphere@polyaniline / polyimide composite film absorbing material, which is characterized in that it comprises the following operation steps:

[0028] (1) Add 4-28ml of ethylenediamine dropwise to the ratio of 0.04g / 1ml FeCl 3 ·6H 2 O / ethylene glycol solution; keep stirring, then put it into the autoclave and react at 150~200℃ for 6~16h; after natural cooling to room temperature, hollow ferroferric oxide microspheres are obtained; the resulting product After being separated from the solvent, it is washed with ethanol and deionized water several times, and dispersed in water for storage;

[0029] (2) To the prepared aqueous dispersion of hollow ferroferric oxide microspheres, add 5-10ml of aniline, keep it at 0-4℃ and keep stirring; after the mixture is uniform, add dropwise to a concentration of 0.2g / ml Of (NH 4 ) 2 S 2 O 8 Aqueous solution, keeping the temperature conditions and stirring rate unchanged during the period, af...

Embodiment 1

[0037] A preparation method of hollow ferroferric oxide microsphere@polyaniline / polyimide composite film absorbing material, including the following operation steps:

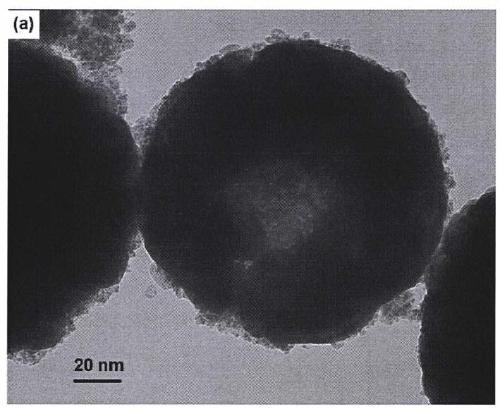

[0038] (1) Under the condition of continuous stirring, add 4ml of ethylenediamine dropwise to 30ml of FeCl with a ratio of 0.04g / 1ml 3 ·6H 2 O / ethylene glycol solution, then put it in an autoclave, and react at 200℃ for 16h; after being naturally cooled to room temperature, hollow ferroferric oxide microspheres with an average outer diameter of 130nm and an average inner diameter of 50nm are obtained ; After separating the resulting product from the solvent, it is washed with ethanol and deionized water several times, and dispersed in water for storage;

[0039] (2) Add 5ml aniline to 1.9×10 -3 g / ml hollow ferroferric oxide microspheres in the aqueous dispersion, keep it at 0~4℃ and keep stirring; after mixing uniformly, add 25ml of 0.2g / ml (NH 4 ) 2 S 2 O 8 Aqueous solution, keep the temperature condition and stirrin...

Embodiment 2

[0044] Preparation method of hollow ferroferric oxide microsphere@polyaniline / polyimide composite film absorbing material, including

[0045] Include the following steps:

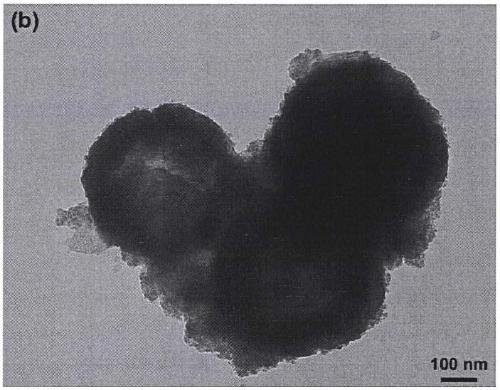

[0046] (1) Under the condition of continuous stirring, add 28ml of ethylenediamine dropwise to 200ml of FeCl with a ratio of 0.04g / 1ml 3 ·6H 2 O / ethylene glycol solution, then put it into the autoclave, react at 150℃ for 9h; after cooling to room temperature, get hollow ferroferric oxide microspheres with an average outer diameter of 500nm and an average inner diameter of 300nm ; After separating the resulting product from the solvent, it is washed with ethanol and deionized water several times, and dispersed in water for storage;

[0047] (2) Add 5ml aniline to 6.7×10 -3 g / ml hollow ferroferric oxide microspheres in the aqueous dispersion, keep 0~4℃ and continue to stir; after mixing uniformly, add 50ml of 0.2g / ml (NH 4 ) 2 S 2 O 8 Aqueous solution, keep the temperature condition and stirring rate unchanged durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average inner diameter | aaaaa | aaaaa |

| Average outer diameter | aaaaa | aaaaa |

| Average outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com