Aqueous exterior wall coating with temperature control mildew resistance and preparation method of coating

A technology for exterior wall coatings and performance, applied in the direction of anti-fouling/underwater coatings, anti-corrosion coatings, coatings, etc., can solve the problems of reduced service life of coatings, achieve long service life, improve construction performance, and good weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

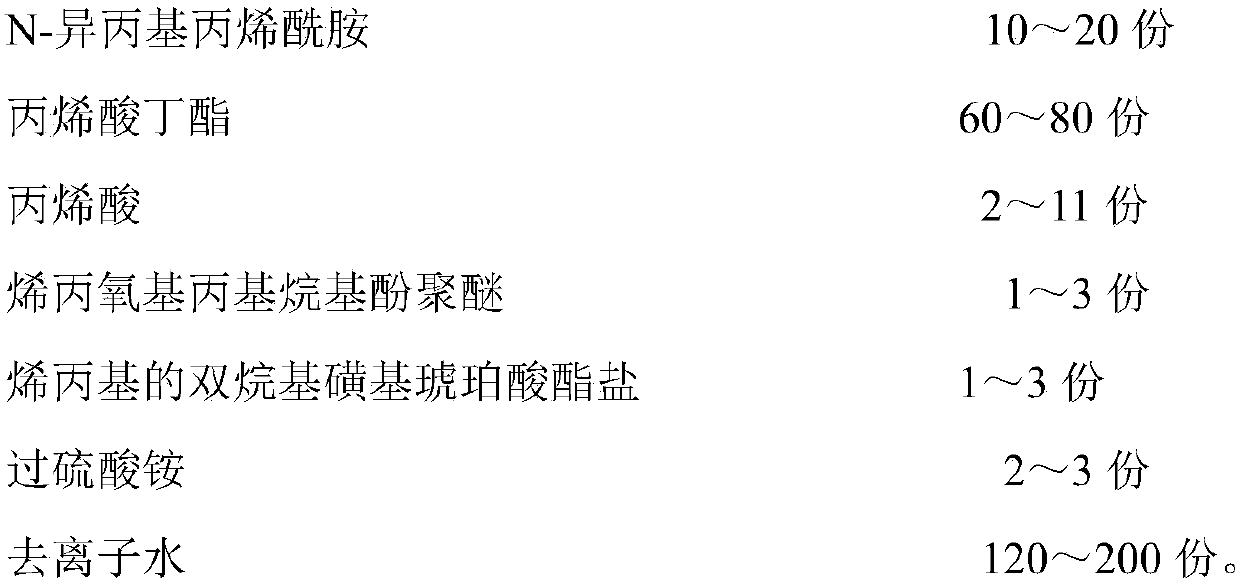

[0045] (1) A kind of isopropylacrylamide modified acrylate emulsion, the preparation steps are as follows:

[0046]First add 10 parts of N-isopropylacrylamide, 60 parts of butyl acrylate, and 2 parts of acrylic acid into a four-necked bottle, stir well, and preheat to 70°C; then add 100 parts of deionized water, 1 part of allyloxy Add propyl propyl alkylphenol polyether and 1 part of allyl dialkyl sulfosuccinate into a four-necked flask, keep the temperature at 70°C, blow nitrogen, and emulsify for 2 hours; then add 2 parts of persulfuric acid Mix ammonium and 20 parts of deionized water evenly, add dropwise to the four-necked bottle, and finish dropping in 2 hours; after the dropwise addition, raise the temperature to 90°C, keep it for 70 minutes, and cool to room temperature; adjust the pH value to 7 with ammonia water, An isopropylacrylamide-modified acrylate emulsion was obtained.

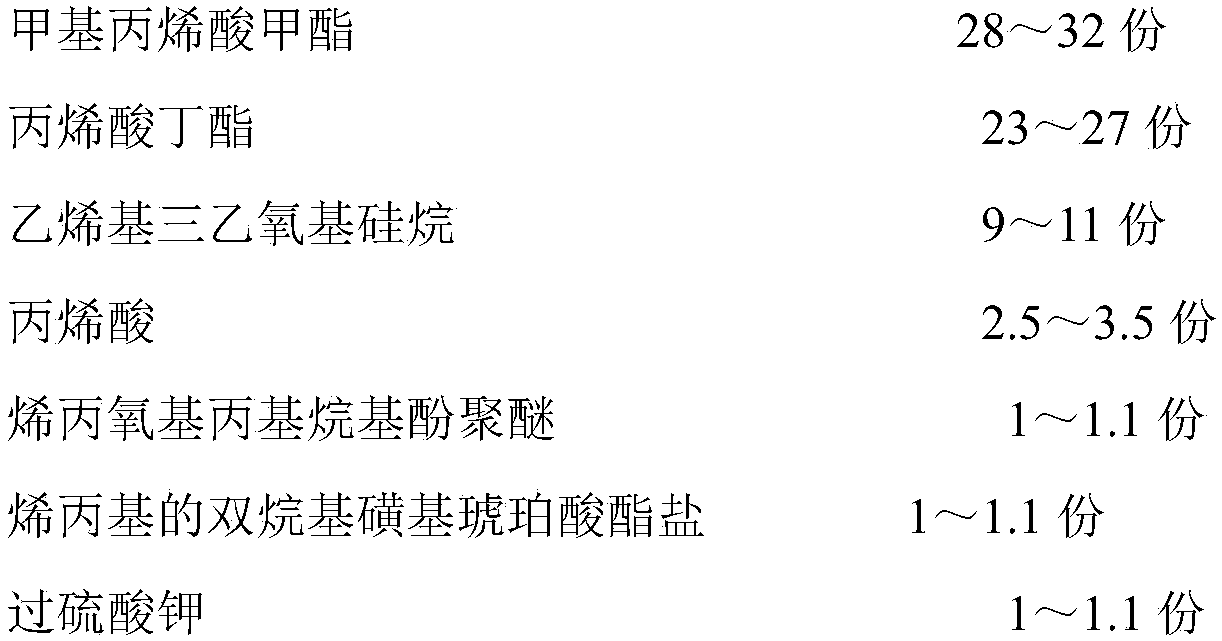

[0047] (2) a silicone modified acrylate emulsion, the preparation steps are as follows:

...

Embodiment 2

[0059] (1) A kind of isopropylacrylamide modified acrylate emulsion, the preparation steps are as follows:

[0060] First add 15 parts of N-isopropylacrylamide, 60 parts of butyl acrylate, and 2 parts of acrylic acid into a four-necked bottle, stir well, and preheat to 70°C; then add 100 parts of deionized water, 1 part of allyloxy Add propyl propyl alkylphenol polyether and 1 part of allyl dialkyl sulfosuccinate into a four-necked flask, keep the temperature at 80°C, blow nitrogen, and emulsify for 2 hours; then add 2 parts of persulfuric acid Mix ammonium and 20 parts of deionized water evenly, add dropwise to the four-necked bottle, and finish dropping in 2 hours; after the dropwise addition, raise the temperature to 90°C, keep it for 70 minutes, and cool to room temperature; adjust the pH value to 7 with ammonia water, An isopropylacrylamide-modified acrylate emulsion was obtained.

[0061] (2) a silicone modified acrylate emulsion, the preparation steps are as follows: ...

Embodiment 3

[0073] (1) A kind of isopropylacrylamide modified acrylate emulsion, the preparation steps are as follows:

[0074] First add 15 parts of N-isopropylacrylamide, 80 parts of butyl acrylate, and 7 parts of acrylic acid into a four-necked bottle, stir well, and preheat to 70°C; then add 100 parts of deionized water, 1 part of allyloxy Add propyl propyl alkylphenol polyether and 1 part of allyl dialkyl sulfosuccinate into a four-necked flask, keep the temperature at 80°C, blow nitrogen, and emulsify for 2 hours; then add 2 parts of persulfuric acid Mix ammonium and 20 parts of deionized water evenly, add dropwise to the four-necked bottle, and finish dropping in 2 hours; after the dropwise addition, raise the temperature to 90°C, keep it for 70 minutes, and cool to room temperature; adjust the pH value to 7 with ammonia water, An isopropylacrylamide-modified acrylate emulsion was obtained.

[0075] (2) a silicone modified acrylate emulsion, the preparation steps are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com