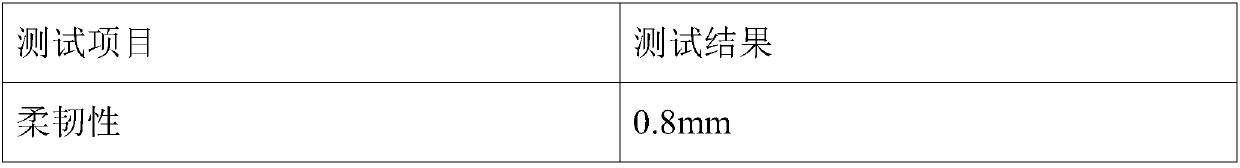

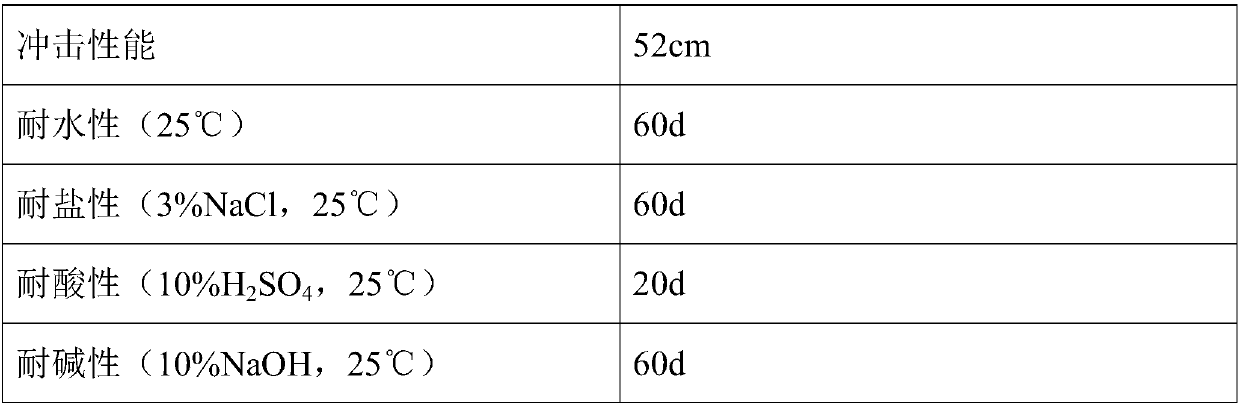

Preparation method for acid-and-alkali-resistant waterborne epoxy coating for ships

A water-based epoxy coating, acid and alkali resistance technology, used in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as poor impact resistance, achieve good acid and alkali resistance, excellent toughening effect, flexibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method of acid and alkali resistant water-based epoxy paint for ships, comprising the steps of:

[0021] S1. Mix 30 kg of cationic silica hydrogel with a mass fraction of 20 wt%, 20 kg of aluminum chloride, 25 kg of citric acid, 60 kg of polyvinyl alcohol 6000, and 320 kg of water, add 2 kg of microcrystalline paraffin and stir for 35 minutes at a temperature of 120 ℃, homogenize until the particle size is 100-130nm, add ammonia water with a concentration of 30wt% dropwise under stirring until the pH of the system is 8.5-9.5, stir for 25min, hydrothermally react for 24h, hydrothermally react at 240℃, centrifuge , washed, dried, calcined at 950°C for 8min, and cooled to obtain the first material;

[0022] S2. Stir 200kg of water, 0.04kg of catalyst, 1.4kg of urea-formaldehyde resin, 1kg of phenol-blocked isocyanate-based polyurethane resin, 2kg of anti-settling agent, 1kg of dispersant, 2.5kg of leveling agent, and 2kg of defoamer, at a stirring spe...

Embodiment 2

[0025] A kind of preparation method of acid and alkali resistant water-based epoxy paint for ships, comprising the steps of:

[0026] S1. Mix 40kg of cationic silica hydrogel with a mass fraction of 16wt%, 30kg of aluminum chloride, 15kg of citric acid, 80kg of polyvinyl alcohol 6000, and 240kg of water, add 4kg of microcrystalline paraffin and stir for 25min at a temperature of 130 ℃, homogenize until the particle size is 100-130nm, add ammonia water with a concentration of 20wt% dropwise under stirring until the pH of the system is 8.5-9.5, stir for 35min, perform hydrothermal reaction for 20h, the temperature of hydrothermal reaction is 260℃, centrifuge , washed, dried, calcined at 850°C for 16 minutes, and cooled to obtain the first material;

[0027] S2. Stir 120kg water, 0.1kg catalyst, 0.6kg urea-formaldehyde resin, 2kg phenol-blocked isocyanate-based polyurethane resin, 1kg anti-settling agent, 2kg dispersant, 1.5kg leveling agent, and 4kg defoamer evenly at a stirring...

Embodiment 3

[0030] A kind of preparation method of acid and alkali resistant water-based epoxy paint for ships, comprising the steps of:

[0031] S1, 33kg mass fraction is 19wt% cationic silica hydrogel, 22kg aluminum chloride, 22kg citric acid, 65kg polyvinyl alcohol 6000, 300kg water are mixed evenly, add 2.5kg microcrystalline paraffin and stir 32min, stirring temperature is 122°C, homogenize until the particle size is 100-130nm, add ammonia water with a concentration of 28wt% dropwise under stirring until the pH of the system is 8.5-9.5, stir for 28min, hydrothermally react for 23h, and the hydrothermally react at a temperature of 245°C. centrifuged, washed, dried, calcined at 920°C for 10 minutes, and cooled to obtain the first material;

[0032] S2, 180kg water, 0.06kg catalyst, 1.2kg urea-formaldehyde resin, 1.3kg phenol-blocked isocyanate-based polyurethane resin, 1.7kg anti-settling agent, 1.4kg dispersant, 2.2kg leveling agent, 2.5kg defoamer are stirred evenly, Stirring speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com