Method for increasing fermentation yield of L-leucine

A leucine and production technology, which is applied in the field of increasing the fermentation production of L-leucine, can solve the problems that the acid production of fermentation needs to be improved, the mixed fermentation process is cumbersome, and the fermentation parameters are difficult to control accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Test strain: Brevibacterium flavum ( Brevibacterium flavum ) TK0303 (Met - +Ile L +2-TA r +α-AB r +β-HL r +Rif r +SG r ), preserved by the Laboratory of Metabolic Engineering, Tianjin University of Science and Technology.

[0031] main instrument

[0032] Fermentation tank (5 L, 30 L automatic fermentation tank, Shanghai Baoxing Biological Equipment Engineering Company); biological sensor (SBA-40C, Institute of Biology, Shandong Academy of Sciences); pH electrode (METTLER TOLEDO); dissolved oxygen electrode (METTLER TOLEDO); high performance liquid chromatography (LC20AT, Shimadzu); TU 1810 UV-Vis spectrophotometer (Beijing General Instrument); electronic balance (FA2204B, Shanghai Precision Scientific Instrument Co., Ltd.).

[0033] training method

[0034] 1. Seed cultivation

[0035] Draw an appropriate amount of sterile normal saline into 5 activated slopes, put the bacterial suspension into a 5 L seed tank, the initial ventilation rate is 1L / min; the sti...

Embodiment 2

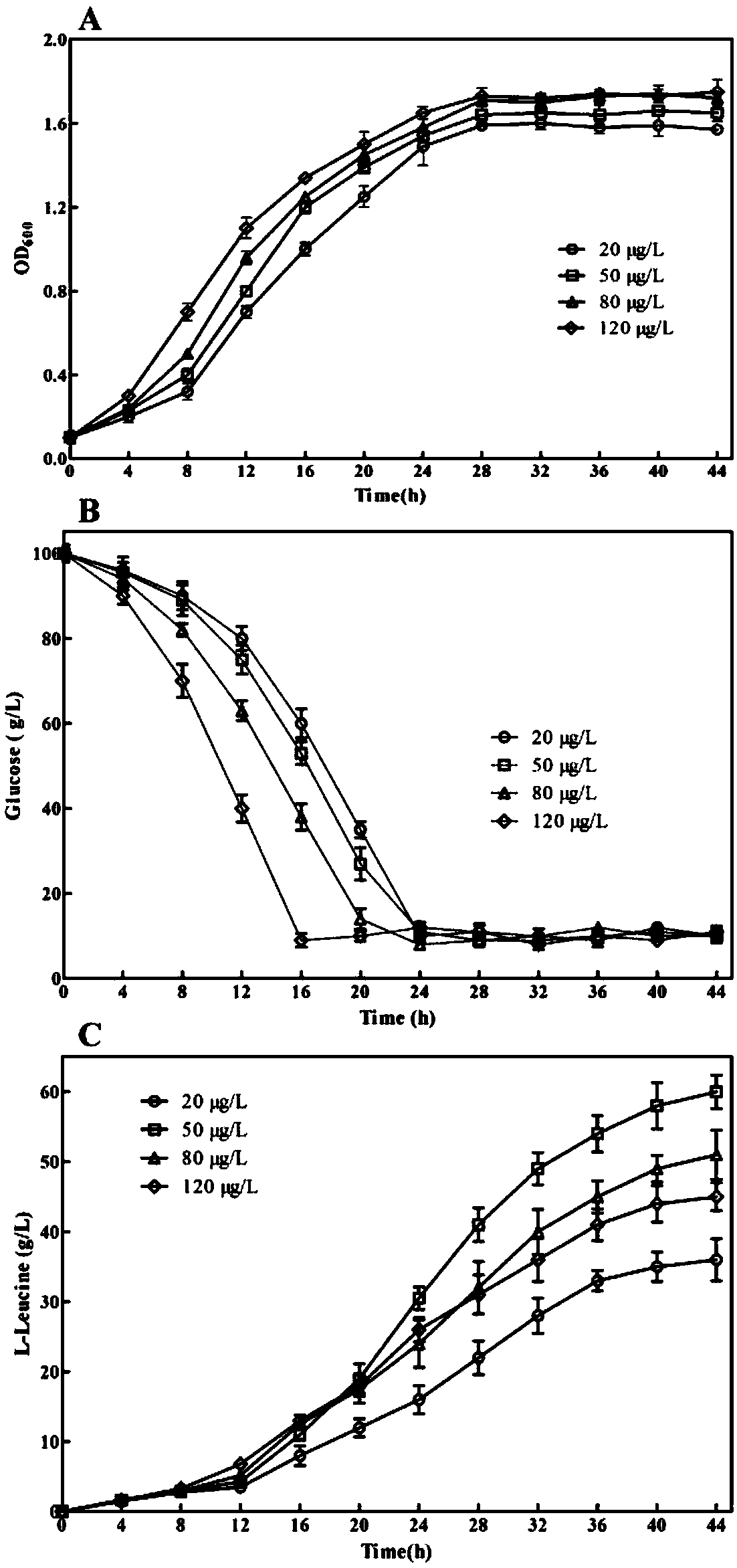

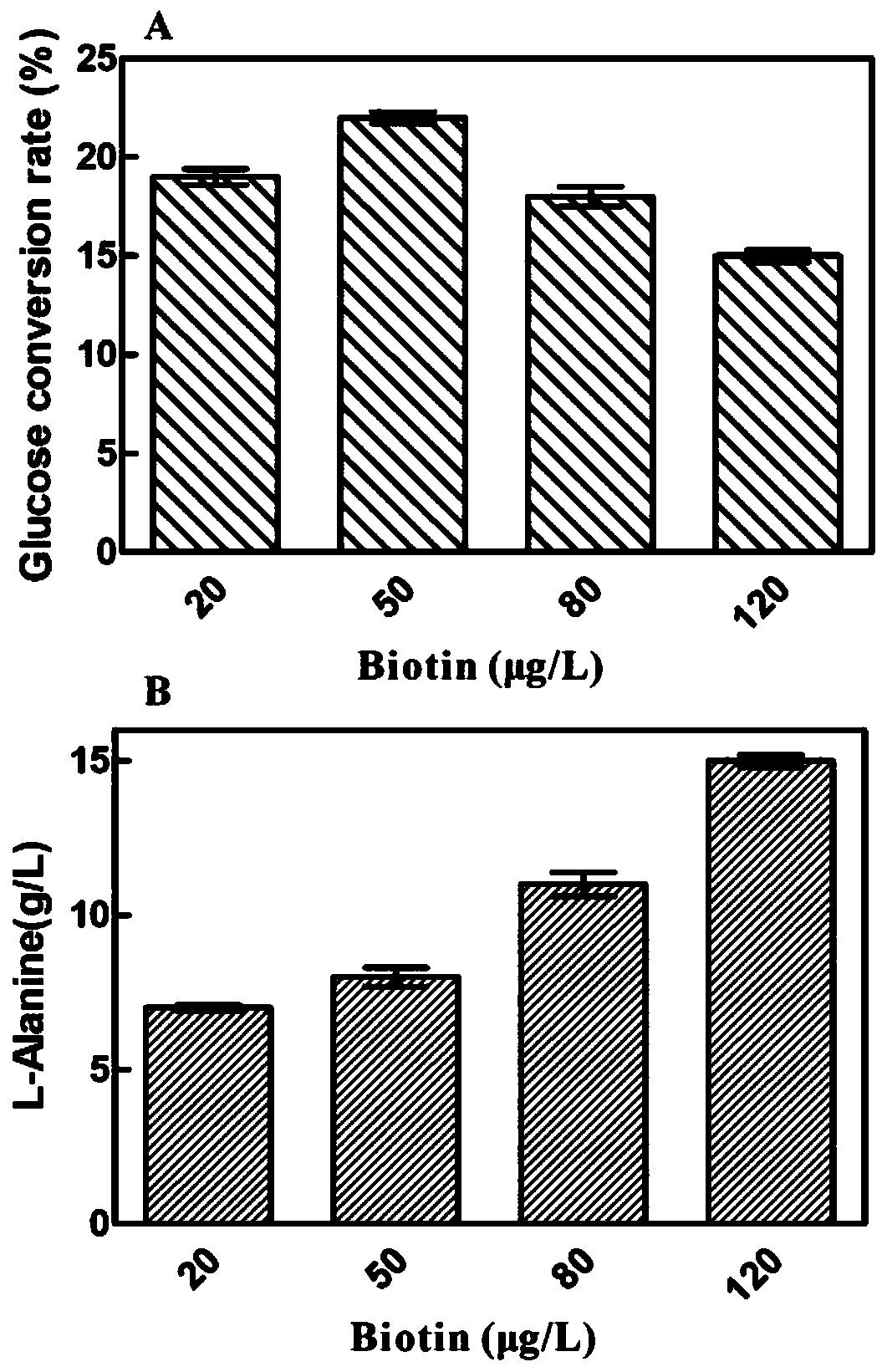

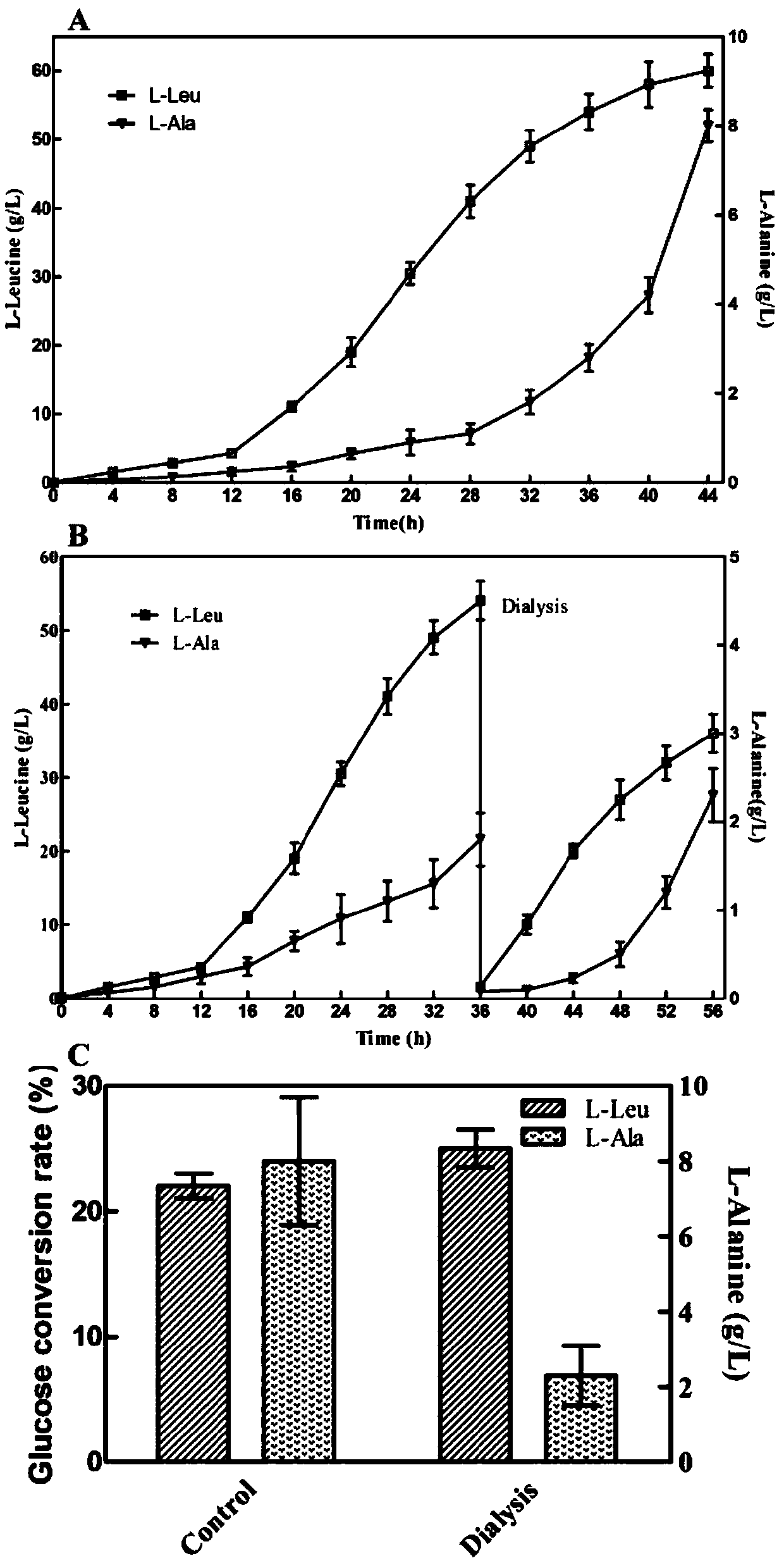

[0041] Put the seed liquid into a 30 L fermenter with 24 L fermenter culture medium according to 10% inoculation amount; the ventilation rate is 2 L / min; the stirring speed is 500 r / min; the pH is controlled at 7.0 by automatic flow of ammonia water; the culture temperature 33°C; use foam to defoam; when the fermentation reaches 20 hours, add the nutrient solution flow into the tank to maintain the sugar concentration in the tank at 1-2g / L; couple the fermenter with a ceramic membrane, and ferment to 36 hours , the fermented liquid in the fermenter is separated by the ceramic membrane, the dialysis filtrate is discharged, the concentrated bacteria are returned to the fermenter, and the fermenter medium is added to the fermenter at the same time, so that the fermented liquid before separation by the ceramic membrane The volume is the same, and the fermentation is continued for 20 hours to complete the fermentation.

[0042] Components of the fermenter culture medium: glucose 50...

Embodiment 3

[0044] Analytical method

[0045] 1. Determination of bacterial concentration

[0046] An appropriate amount of fermentation broth was taken every 4 h, diluted with sterilized physiological saline, and the absorbance at 600 nm wavelength was measured by a spectrophotometer.

[0047] 2. Determination of dissolved oxygen and pH

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com