Core-shell nickel hydroxide nanosheet/manganese-cobalt oxide composite electrode material and preparation method thereof

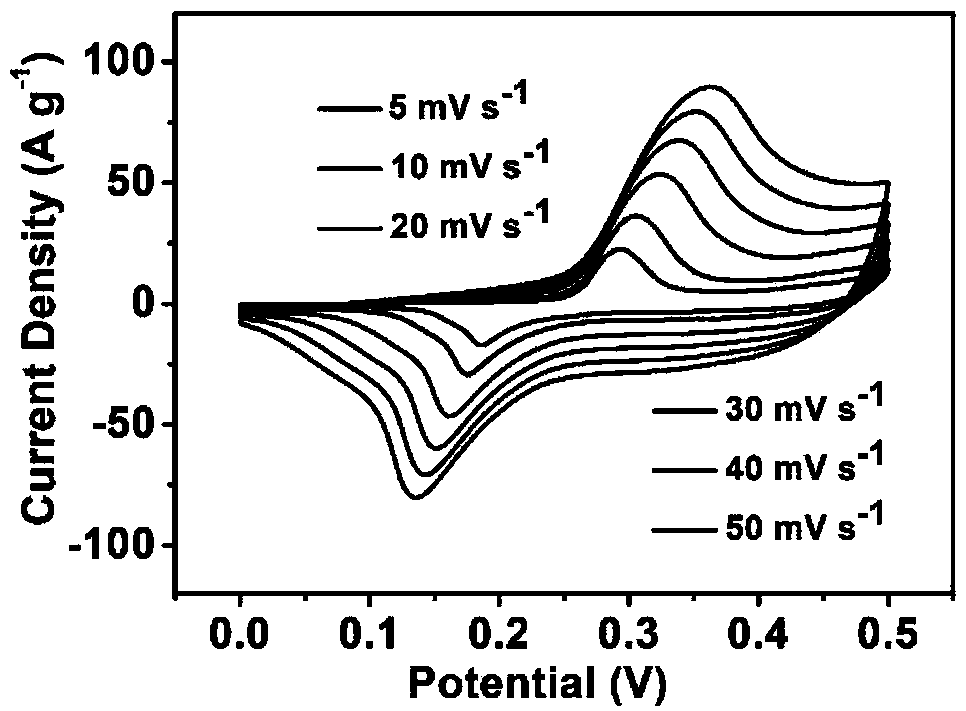

A nickel hydroxide and composite electrode technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of poor cycle stability and low capacitance of manganese cobalt oxide, and achieve high charge and discharge stability, The effect of high repeatability and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

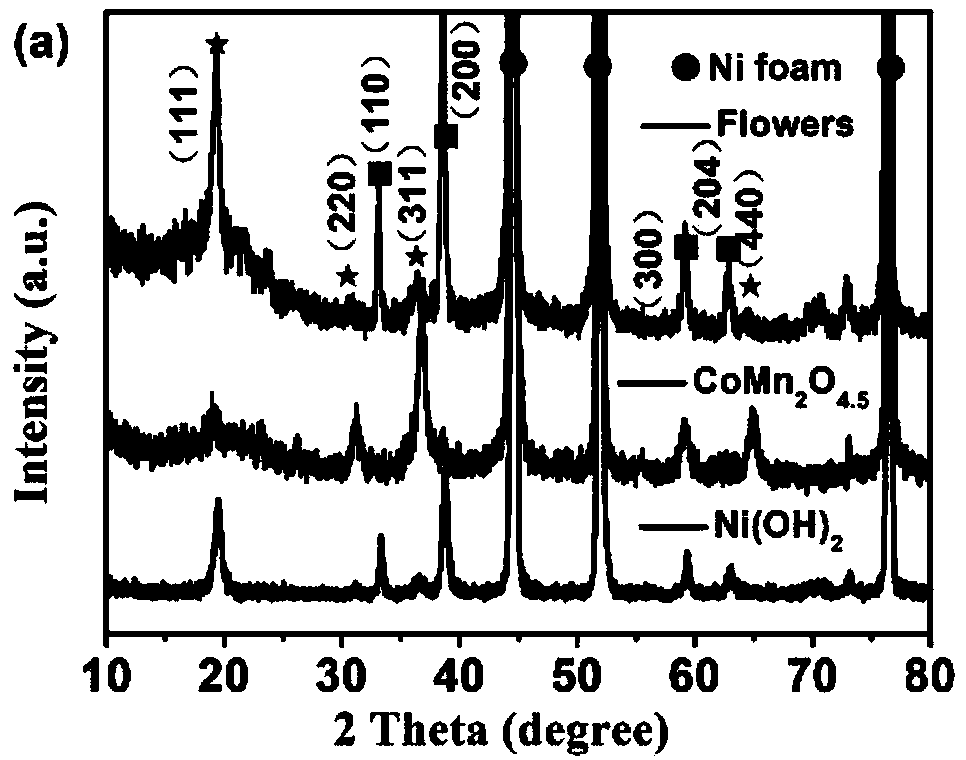

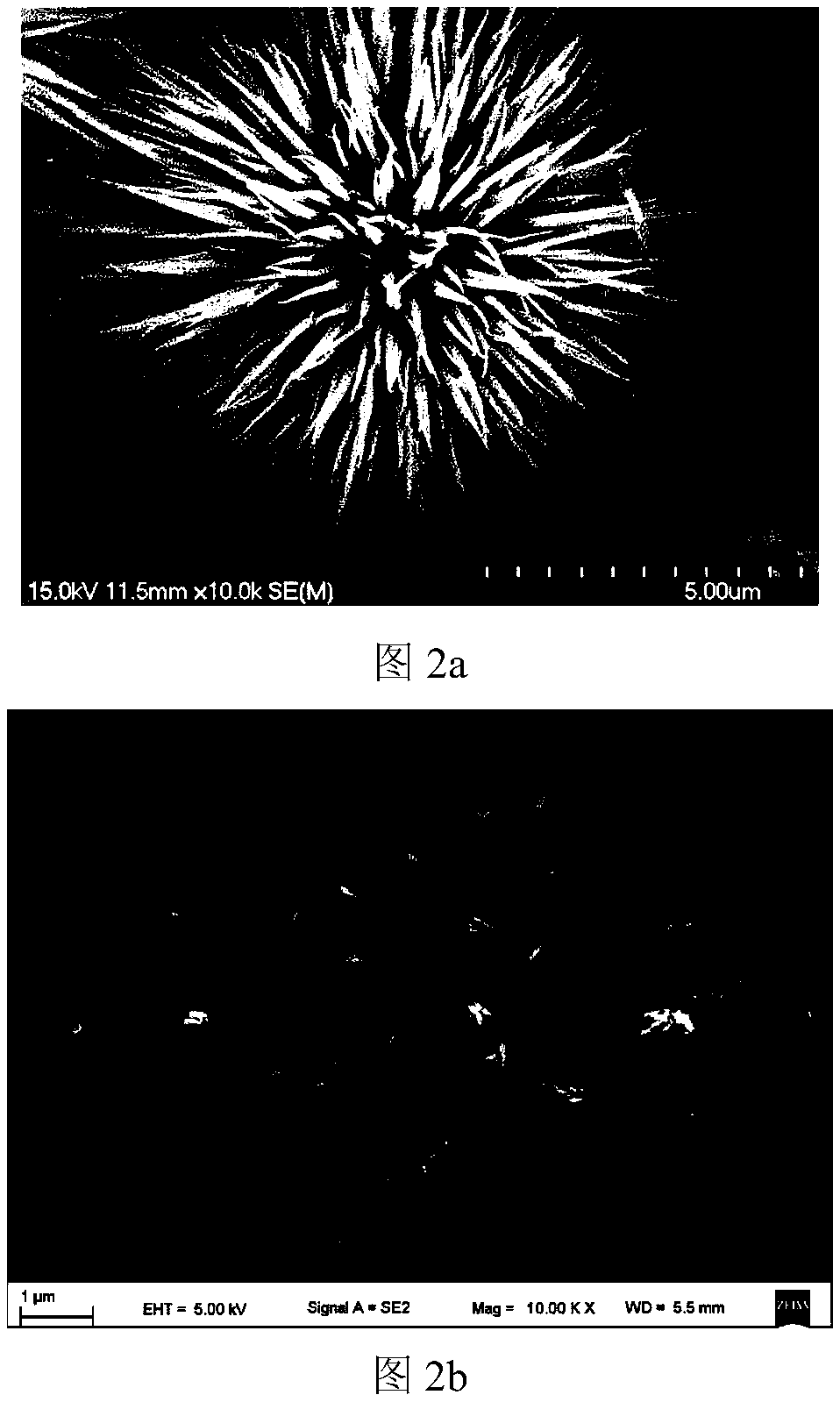

[0063] A kind of nickel hydroxide nanosheet / manganese cobalt oxide composite electrode material of the present invention is based on MnCo 2 o 4.5 As the nucleus, nickel hydroxide nanosheets are uniformly grown on its surface.

[0064] The present invention also provides a method for preparing the aforementioned nanoflower core-shell nickel hydroxide nanosheet / manganese cobalt oxide composite electrode material, comprising the following steps:

[0065] (1) Ultrasonic dispersion of cobalt chloride hexahydrate, manganese chloride tetrahydrate, ammonium fluoride and urea in deionized water (power is 500-600W) to obtain a uniformly mixed solution;

[0066] In the above mixed solution, calculated per liter, its components and contents are as follows:

[0067]

[0068] (2), transfer the mixed solution obtained in step (1) into a hydrothermal kettle, then put into 10mm×50mm foam nickel, and react in hydrothermal reaction at 120° C. for 6 hours, then rinse with absolute ethanol an...

Embodiment 2

[0081] A kind of nickel hydroxide nanosheet / manganese cobalt oxide composite electrode material of the present invention is based on MnCo 2 o 4.5 As the nucleus, nickel hydroxide nanosheets are uniformly grown on its surface.

[0082] The present invention also provides a method for preparing the aforementioned nanoflower core-shell nickel hydroxide nanosheet / manganese cobalt oxide composite electrode material, comprising the following steps:

[0083](1) Ultrasonic dispersion of cobalt chloride hexahydrate, manganese chloride tetrahydrate, ammonium fluoride and urea in deionized water (power is 500-600W) to obtain a uniformly mixed solution;

[0084] In the above mixed solution, calculated per liter, its components and contents are as follows:

[0085]

[0086] (2), transfer the mixed solution obtained in step (1) into a hydrothermal kettle, then put into 10mm×50mm nickel foam, and react in hydrothermal reaction at 140° C. for 6 hours, then rinse with absolute ethanol and...

Embodiment 3

[0093] A kind of nickel hydroxide nanosheet / manganese cobalt oxide composite electrode material of the present invention is based on MnCo 2 o 4.5 As the nucleus, nickel hydroxide nanosheets are uniformly grown on its surface.

[0094] The present invention also provides a method for preparing the aforementioned nanoflower core-shell nickel hydroxide nanosheet / manganese cobalt oxide composite electrode material, comprising the following steps:

[0095] (1), cobalt chloride hexahydrate, manganese chloride tetrahydrate, ammonium fluoride and urea are dispersed in deionized water uniformly under the control power of 500-600W and ultrasonic conditions at room temperature to obtain a mixed solution;

[0096] In the above mixed solution, calculated per liter, its components and contents are as follows:

[0097]

[0098] (2), transfer the mixed solution obtained in step (1) into a hydrothermal kettle, then add nickel foam with a length of 1*5CM, and carry out hydrothermal reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com