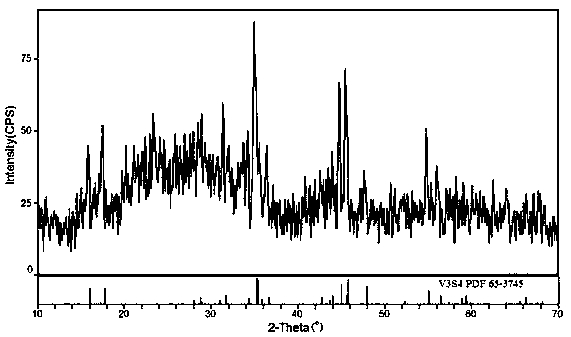

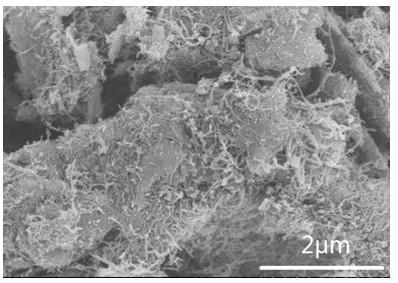

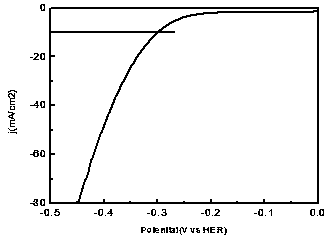

Preparation of V3S4@CNTS and application of electrocatalytic performance thereof

A technology of electrocatalyst and inert atmosphere, which is applied in the synthesis field of V3S4@CNTS electrocatalyst, can solve the problems of lowering the reaction energy barrier, achieve the effects of high purity and crystallinity, cheap raw materials, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Weigh 4mmol of oxalic acid and 2mmol of V 2 O 5 and 50mg of carbon nanotubes were dissolved in 30mL of deionized water, and the mixed solution was obtained after magnetic stirring for 30min;

[0023] Step 2: Pour the prepared solution into the reaction polytetrafluoroethylene lining, the filling ratio of the reaction kettle is 80%, and put the inner lining into the outer kettle, put it in an oven after fixing, and the reaction conditions Incubate at 180°C for 24h.

[0024] Step 3: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction solution is poured out and washed 5 times with deionized water and absolute ethanol. After suction filtration, the samples were collected and dried under vacuum at 60 °C for 24 h to obtain the vanadium oxide composite material.

[0025] Step 4: control the molar ratio of vanadium oxide composite material and thioacetamide to be 1:12, spread the two raw mate...

Embodiment 2

[0030] Step 1: Weigh 4mmol of oxalic acid and 2mmol of V 2 O 5 and 50mg of carbon nanotubes were dissolved in 30mL of deionized water, and the mixed solution was obtained after magnetic stirring for 30min;

[0031] Step 2: Pour the prepared solution into the reaction polytetrafluoroethylene lining, the filling ratio of the reaction kettle is 80%, and put the inner lining into the outer kettle, put it in an oven after fixing, and the reaction conditions Incubate for 24h at 200°C.

[0032] Step 3: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction solution is poured out and washed three times with deionized water and absolute ethanol each. After suction filtration, the samples were collected and dried under vacuum at 80 °C for 12 h to obtain the vanadium oxide composite material.

[0033] Step 4: Control the molar ratio of the vanadium oxide composite material to the sublimated sulfur to be 1:15, spr...

Embodiment 3

[0037] Step 1: Weigh 4mmol of oxalic acid and 2mmol of V 2 O 5 and 70 mg of carbon nanotubes were dissolved in 30 mL of a mixed solution of ethylene glycol and deionized water (1:1), and the mixed solution was obtained after magnetic stirring for 30 min.

[0038] Step 2: Pour the prepared solution into the reaction polytetrafluoroethylene lining, the filling ratio of the reaction kettle is 80%, and put the inner lining into the outer kettle, put it in an oven after fixing, and the reaction conditions Incubate for 24h at 160°C.

[0039]Step 3: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction solution is poured out and washed three times with deionized water and absolute ethanol each. After suction filtration, the samples were collected and dried under vacuum at 60 °C for 24 h to obtain the vanadium oxide composite material.

[0040] Step 4: control the molar ratio of vanadium oxide composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com