Nondestructive cleaning method for laser gyroscope cavity after optical machining

An optical processing and laser gyro technology, which is applied in the direction of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc. Corrosion etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

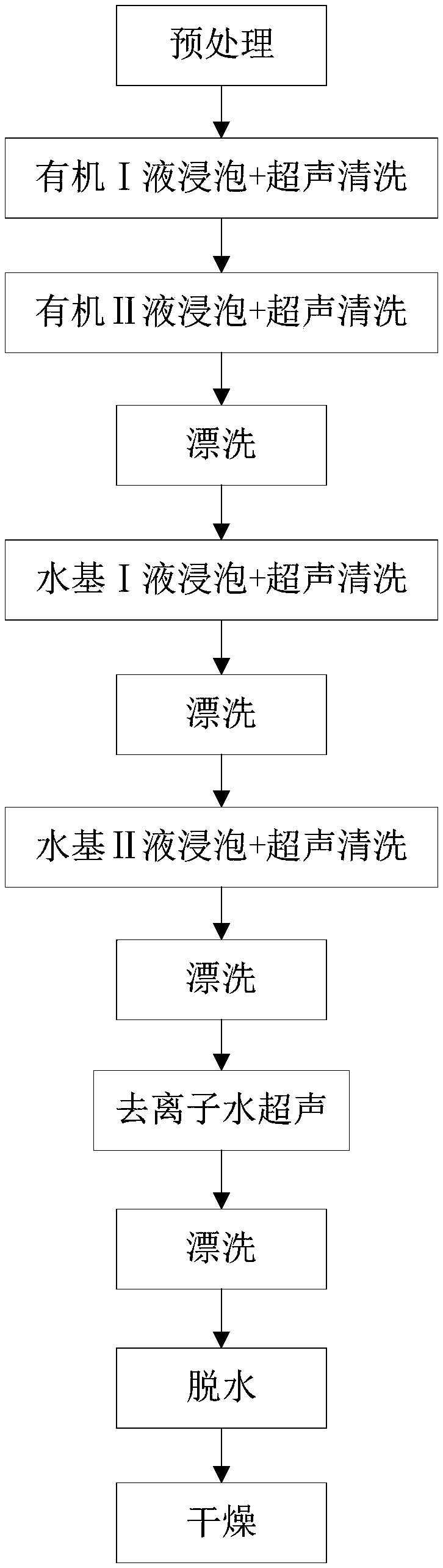

[0052] After the laser gyro cavity is polished with ceria polishing powder, clean it according to the following steps:

[0053] (1) Tear off the protective film on the surface of the cavity with bare hands, blow and soften the rosin wax in the cavity hole with a hot melt gun, and at the same time wipe off the melted rosin wax with a cotton swab;

[0054] (2) Soak the cavity in aviation gasoline. After soaking for 60 minutes, the residual rosin wax on the hole wall of the cavity becomes softened. Place the aviation gasoline containing the cavity in an ultrasonic cleaning machine for 6 minutes and ultrasonic frequency is 40kHz;

[0055] (3) Take out the cavity, soak the cavity in acetone, after soaking for 60 minutes, the protective paint on the surface of the cavity will soften, place the acetone containing the cavity in an ultrasonic cleaner for 6 minutes, and the ultrasonic frequency is 40kHz;

[0056] (4) Take out the chamber and rinse the chamber with 50°C deionized water; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com