Industrial heavy metal sewage treatment method based on flocculation, flotation and sedimentation

A sewage treatment method and heavy metal technology, applied in the direction of flotation water/sewage treatment, sedimentation treatment, water/sewage treatment, etc., can solve the problems of unstable removal effect, secondary pollution treatment cost, etc., and achieve stable and enhanced treatment effect Effect of flocculation, good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

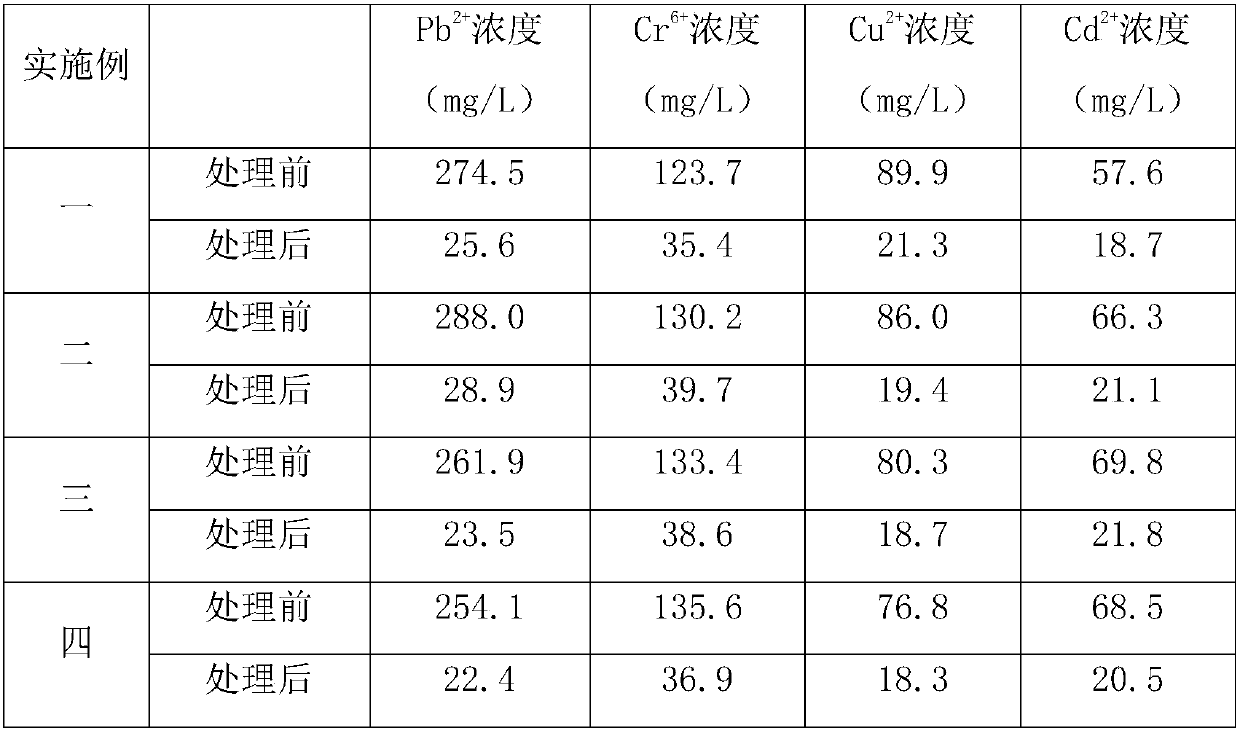

Examples

Embodiment 1

[0035] Preparation of modified shell powder: Wash the shells and dry them at 60°C, add 0.1mol / L nitric acid solution, and reflux at 75°C for 2 hours. After the reaction, take out the shells and wash them with deionized water until medium After drying, place it in a calciner, heat up to 700°C and calcinate for 4 hours, take it out after cooling to room temperature with the furnace, and pulverize it with a nano pulverizer to obtain modified shell powder.

[0036] Prepare chitosan acetic acid solution: weigh 2g chitosan, add 100mL water, then add 2mL glacial acetic acid, stir evenly, heat to 85°C, add water to 100mL, keep warm for 45min to obtain 1% chitosan acetic acid solution .

[0037] Preparation of modified water hyacinth airbag fiber bundle tube: Take healthy water hyacinth plants with an average diameter of 2.5cm to 4.5cm at the airbag part, cut to obtain the airbag and the plant stem 0.5cm above and below the airbag, and vacuum dry to the moisture content of the plant st...

Embodiment 2

[0047] The preparation of the modified shell powder is the same as in Example 1.

[0048] Preparation chitosan acetic acid solution is identical with embodiment one.

[0049] Preparation of modified water hyacinth airbag fiber bundle tube: Take healthy water hyacinth plants with an average diameter of 2.5cm to 4.5cm at the airbag part, cut to obtain the airbag and the plant stem 0.5cm above and below the airbag, and vacuum dry to the moisture content of the plant stem about 25%, peel off the surface layer, then cut the surface layer obtained by peeling it off, pass through a 30-mesh sieve, then add 0.8% by weight of modified shell powder, mix evenly, and obtain the airbag fiber bundle tube, take the airbag fiber bundle The tube is mixed with the same mass of polyaluminum ferric chloride to obtain a solid mixture, and the solid mixture is heated to 70°C by far infrared, stirred during the heating process, and sprayed with 1% chitosan acetic acid solution at the same time, where...

Embodiment 3

[0054] The preparation of the modified shell powder is the same as in Example 1.

[0055] Preparation chitosan acetic acid solution is identical with embodiment one.

[0056] Preparation of modified water hyacinth airbag fiber bundle tube: Take healthy water hyacinth plants with an average diameter of 2.5cm to 4.5cm at the airbag part, cut the airbag and the plant stem 1cm above and below the airbag, and vacuum dry until the moisture content of the plant stem is About 20%, peel off the surface layer, then cut the surface layer obtained by peeling it off, pass through a 30-mesh sieve, then add 0.15% by weight of modified shell powder, mix evenly, and obtain the airbag fiber bundle tube, take the airbag fiber bundle tube Mix with equal mass of polyaluminum ferric chloride to obtain a solid mixture, heat the solid mixture to 72°C by far-infrared, stir during the heating process, and spray 1% chitosan acetic acid solution at the same time, wherein the chitosan acetic acid solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com