High-weather-resistance automotive paint

A technology of weather resistance and automotive paint, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as profit margins reduce competitiveness, paint performance, and environmental protection requirements cannot be met, so as to improve the combination efficiency, Effects of improving compactness and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of automotive paint: Add 2kg of talc powder, 1kg of nano-alumina, and 1kg of glass fiber into the reaction kettle, stir at 30°C for 10 minutes, raise the temperature to 50°C, add 20kg of urea-formaldehyde resin, 2kg of fumed silica, and 4kg of silane coupling agent to continue Stir for 30 minutes, then add 40kg of modified epoxy resin, 15kg of fluorocarbon resin, and 6kg of weathering agent into the reactor, seal the reactor and fill it with nitrogen to make the pressure reach 5-6MPa, then raise the temperature to 115°C to the pressure inside the reactor Reach 8-9MPa, react for 4 hours, cool the reactor to 35°C, release the gas, discharge when the pressure is zero, wash, and dry at room temperature.

[0026] Preparation of modified epoxy resin: Add 30kg EPDM rubber into absolute ethanol, heat to reflux state, keep stirring for 5min, then add 6kg acrylic acid and 2kg trimethylolpropane to reflux and stir for 1h, then add 30kg bis Phenol A epoxy resin was refl...

Embodiment 2

[0029] Preparation of automobile paint: Add 3kg talcum powder, 2kg nano-alumina, and 1kg glass fiber into the reaction kettle, stir at 30°C for 10 minutes, heat up to 50°C, add 25kg urea-formaldehyde resin, 2kg fumed silica, and 4kg silane coupling agent to continue Stir for 30 minutes, then add 42kg of modified epoxy resin, 16kg of fluorocarbon resin, and 8kg of weathering agent into the reactor, seal the reactor and fill it with nitrogen to make the pressure reach 5-6MPa, then raise the temperature to 115°C to the pressure inside the reactor Reach 8-9MPa, react for 4 hours, cool the reactor to 35°C, release the gas, discharge when the pressure is zero, wash, and dry at room temperature.

[0030] Preparation of modified epoxy resin: Add 30kg EPDM rubber into absolute ethanol, heat to reflux state, keep stirring for 5min, then add 6kg acrylic acid and 2kg trimethylolpropane to reflux and stir for 1h, then add 30kg bis Phenol A epoxy resin was refluxed and stirred for 2 hours, ...

Embodiment 3

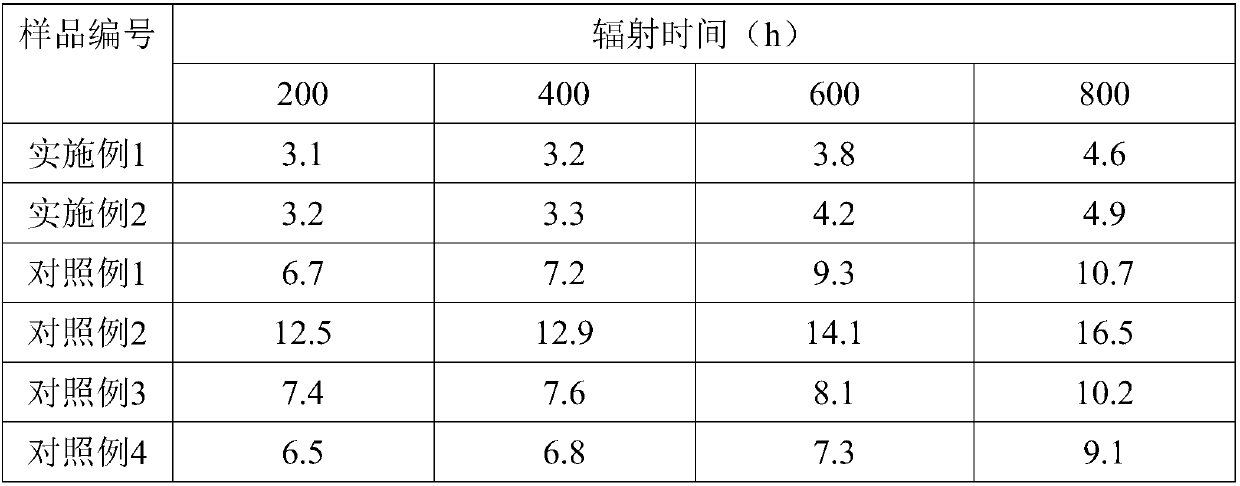

[0048] Based on Example 1, set up the comparative example 1 without adding acrylic acid, the comparative example 2 without modifying the epoxy resin, the comparative example 3 without adding epoxy soybean oil and almond oil, and the comparison using weather resistance agent UV-531 Example 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com