A method for simultaneous determination of three kinds of bisphenols content

A technology of substance content and bisphenols, which is applied in the field of detection of harmful substance residues, can solve the problems of difficulty in guaranteeing the extraction effect, low amount of extraction agent, and poor extraction reproducibility, and achieve rapid phase separation, good reproducibility, and emulsion formation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Detection of bisphenol A content in bottled water and buckets

[0017] 1. Preparation of deep eutectic solvent: Mix n-octanoic acid and n-decanoic acid in a molar ratio of 2:1, heat to 70°C to form a uniform transparent solution, that is, form a deep eutectic solvent.

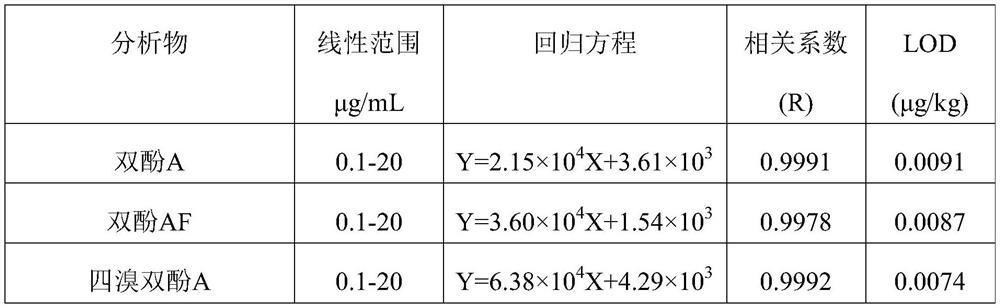

[0018] 2. Working curve making: prepare 0.1, 0.5, 1, 2, 5, 10, 20 μg / mL bisphenol A standard solutions respectively, liquid chromatography conditions: mobile phase is acetonitrile-water, V (acetonitrile): V (water )=60:40, flow rate 1mL / min, detection wavelength 224nm, autosampler injection, injection volume 10μL. Its linear range, regression equation and correlation coefficient are shown in Table 1.

[0019] Table 1 Bisphenols linear range, regression equation, correlation coefficient

[0020]

[0021] Table 2 bisphenols standard addition recovery (%) n=6

[0022]

[0023]

[0024] 3. Determination of bisphenol A in bottled water: Take 50mL bottled water, filter it through a 0.45μ...

Embodiment 2

[0026] Embodiment 2: the mensuration of bisphenol A and bisphenol AF content in canned pork

[0027] 1. Preparation of deep eutectic solvent: Mix n-nonanoic acid, n-decanoic acid, and undecanoic acid in a molar ratio of 3:1:1, heat to 75°C to form a uniform transparent solution, that is, form a deep eutectic solvent.

[0028] 2. Preparation of working curves: Prepare 0.1, 0.5, 1, 2, 5, 10, 20 μg / mL bisphenol A and bisphenol AF mixed standard solutions respectively. See Table 1 for the linear range, regression equation and correlation coefficient. Rates are shown in Table 2. Chromatographic conditions: AgilentEclipse plus C18 column (2.1mm×100mm, 3.5μm), column temperature is 30°C; mobile phase A is water, mobile phase B is methanol, gradient elution; gradient elution program is: (0-3 ) min, 50% B, (3-7) min, 50% B-80% B, (7-15) min, 80% B, (3-7) min, 80% B-50% B; the flow rate is 1.0mL / min; detection wavelength: 280nm; injection volume: 10μL.

[0029] 3. Pretreatment of can...

Embodiment 3

[0033] Embodiment 3: Determination of bisphenols in plastic packaging materials

[0034] 1. Preparation of deep eutectic solvent: Mix n-nonanoic acid, undecanoic acid, and dodecanoic acid in a molar ratio of 2:1:1, and heat to 80°C to form a uniform transparent solution, that is, a deep eutectic solvent.

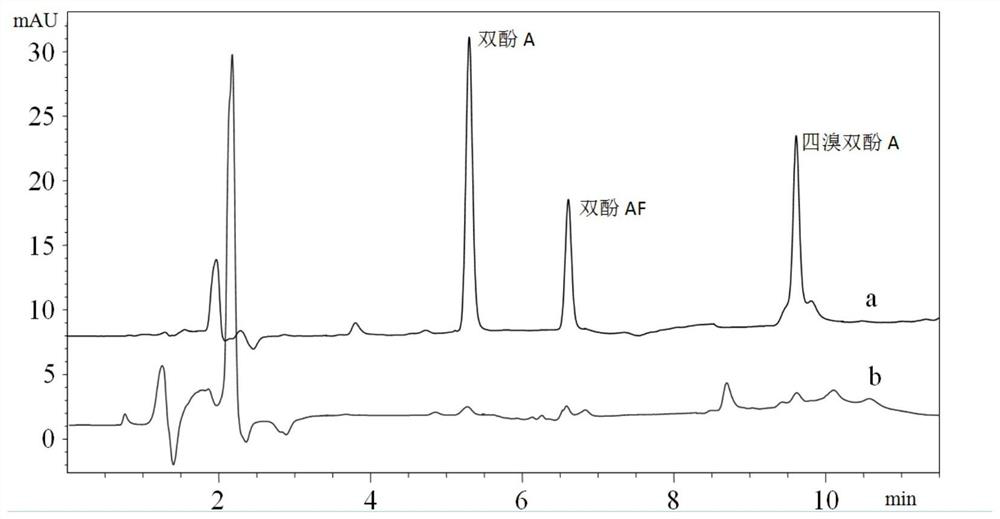

[0035] 2. Working curve creation: prepare 0.1, 0.5, 1, 2, 5, 10, 20 μg / mL bisphenol A, bisphenol AF, tetrabromobisphenol A mixed standard solutions respectively, see the linear range, regression equation and correlation coefficient Table 1, the recovery rate of standard addition is shown in Table 2, and the chromatograms of 0.50 μg / kg bisphenol A, bisphenol AF and tetrabromobisphenol A treated with micro-extraction of the present invention and without micro-extraction are shown in Table 2. figure 1 , the chromatographic conditions are the same as in Example 2.

[0036] 3. Pretreatment of samples of bisphenols in plastic packaging materials: crush the samples of plastic pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com