Spunbonded nonwoven fabric and production method therefor

A technology of spunbond nonwoven fabrics and manufacturing methods, applied in textiles and papermaking, chemical instruments and methods, nonwoven fabrics, etc., can solve problems such as curling in the width direction of spunbond nonwoven fabrics, and achieve excellent spinnability, surface Effect of smooth and firm film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

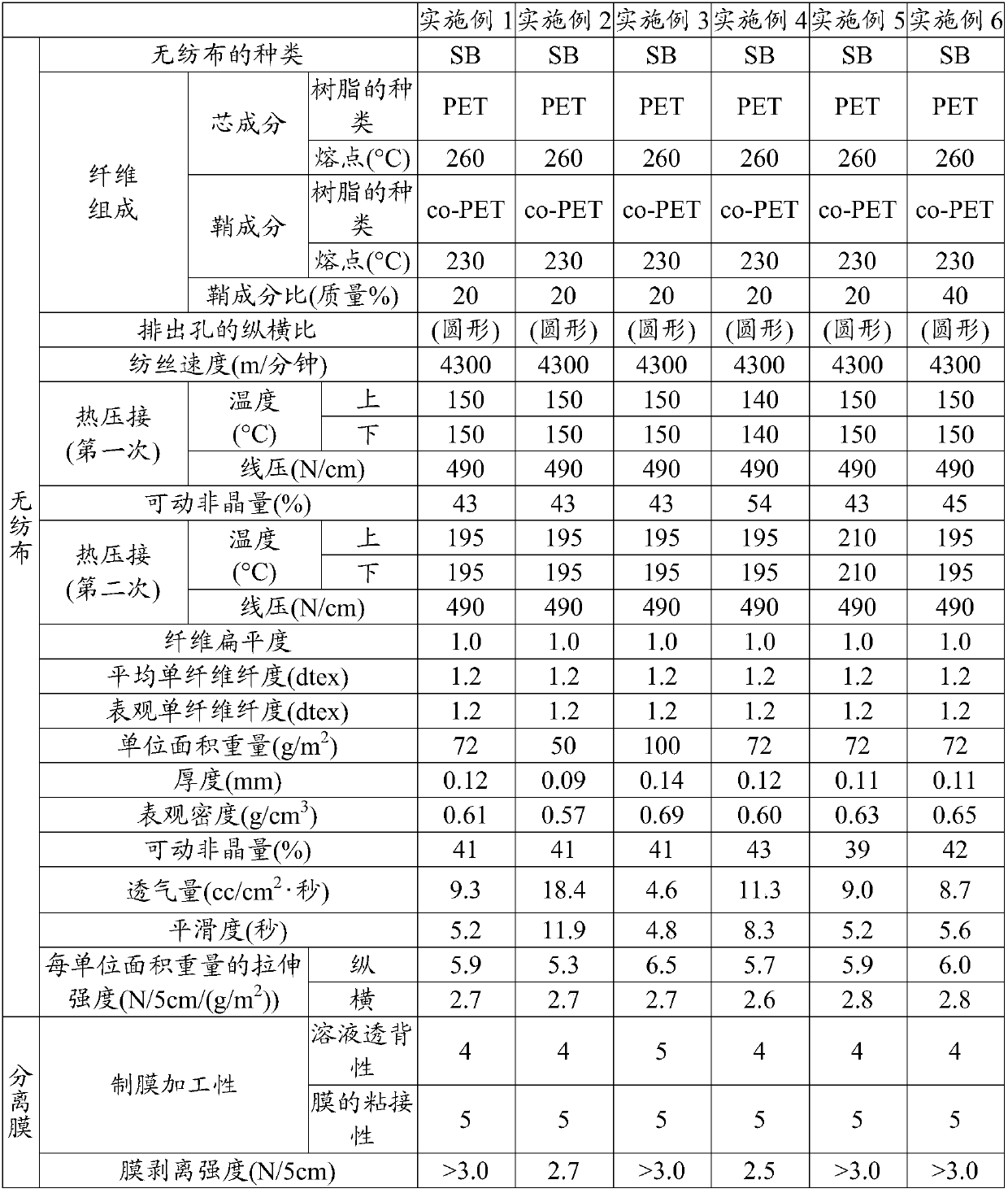

Examples

Embodiment 1

[0193] (core ingredient)

[0194] A polyethylene terephthalate resin having an intrinsic viscosity (IV) of 0.65, a melting point of 260° C., and a titanium oxide content of 0.3% by mass was dried to a moisture content of 50 ppm or less, and was used as a core component.

[0195] (sheath component)

[0196] A copolymerized polyethylene terephthalate resin having an intrinsic viscosity (IV) of 0.66, a copolymerization rate of isophthalic acid of 11 mol%, a melting point of 230°C, and a titanium oxide content of 0.2% by mass is dried to a moisture content of 50 ppm or less , the resin thus obtained was used as a sheath component.

[0197] (spun and non-woven mesh capture)

[0198] The above-mentioned core component and sheath component were melted at 295°C and 270°C, respectively, and the mass ratio of the core component and sheath component was 80 / 20 under the condition of the spinneret temperature of 300°C, and the compound was formed into a concentric core-sheath type (circul...

Embodiment 2

[0206] (spunbonded nonwoven fabric)

[0207] Make the weight per unit area of the spunbond nonwoven fabric 50g / m 2 , except that, in the same manner as in Example 1, the apparent single fiber fineness was 1.2dtex, and the weight per unit area was 50g / m 2 , thickness is 0.09mm, apparent density is 0.57g / cm 3 , Movable amorphous volume is 41%, Air permeability is 21.8cc / cm 2 • A spun-bonded nonwoven fabric with a Buick smoothness of 11.9 seconds on both sides.

[0208] (Separation Membrane Formation)

[0209] Furthermore, a polysulfone membrane was formed into a membrane in the same manner as in Example 1 with respect to the obtained spunbonded nonwoven fabric. At this time, the cast solution was slightly shown through, and the film was not bent from unwinding to winding, and peeling of the film was not observed, and the film forming property was good. The peel strength of the obtained polysulfone membrane was 2.7 N / 5 cm. The results are shown in Table 1.

Embodiment 3

[0211] (spunbonded nonwoven fabric)

[0212] Make the unit area weight of the spunbonded nonwoven fabric 100g / m 2 , except that, in the same manner as in Example 1, the apparent single fiber fineness was 1.2dtex, and the weight per unit area was 100g / m 2 , thickness is 0.14mm, apparent density is 0.70g / cm 3 , Movable amorphous volume is 41% あり, Air permeability is 4.6cc / cm 2 Spun-bonded non-woven fabric with Buick smoothness of 4.8 seconds.

[0213] (Separation Membrane Formation)

[0214] Furthermore, a polysulfone membrane was formed into a membrane in the same manner as in Example 1 with respect to the obtained spunbonded nonwoven fabric. At this time, no back-through of the casting solution occurred, the film was not bent from unwinding to winding, and peeling of the film was not observed, and the film forming property was good. As for the peel strength, it could not be measured because the polysulfone membrane was broken during the test, and the membrane was firmly b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com