FTrPSA hydrogen extraction method for recycle hydrogen during propane dehydrogenation to propylene

A technology of propane dehydrogenation and circulating hydrogen, applied in chemical instruments and methods, hydrogen separation, hydrocarbons, etc., can solve the problems of high energy consumption, high investment and operating costs, and achieve low equipment investment costs and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

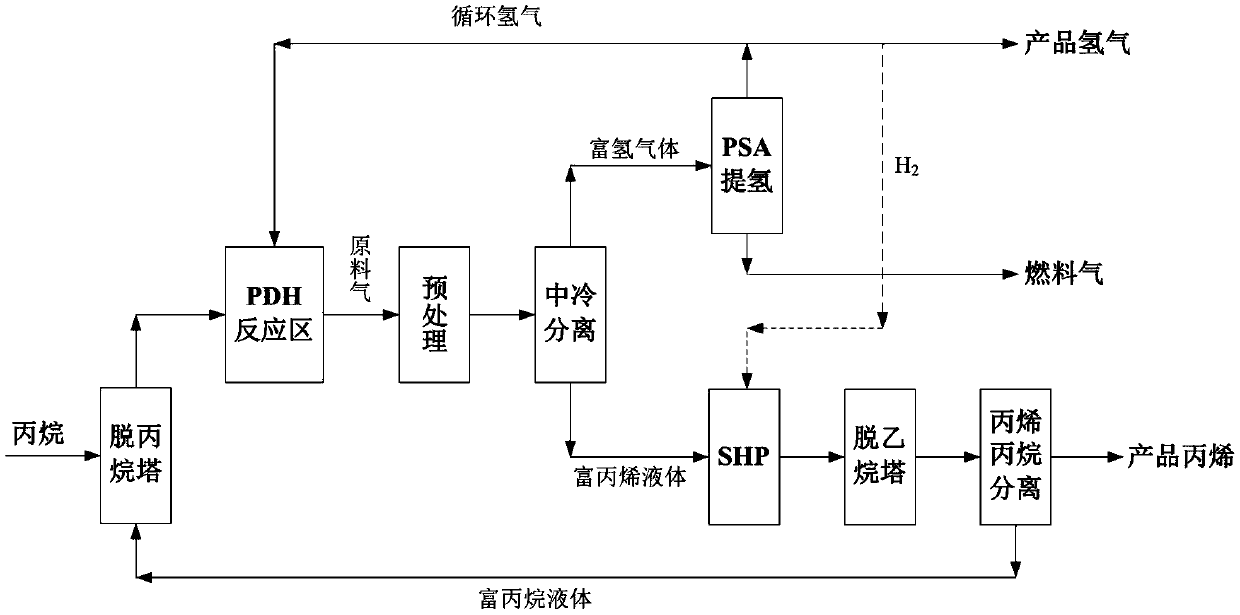

[0039] Such as figure 1 Shown, a kind of FTrPSA hydrogen extraction method of propane dehydrogenation propylene circulation hydrogen, concrete implementation steps comprise,

[0040] (1) Pretreatment process, the reactant mixed gas from the propane dehydrogenation to propylene (PDH) reaction zone, as the raw material gas, its main component is propylene of 35% to 40% (volume ratio, the following is similar), 40 ~55% hydrogen, and the remaining components include methane, ethane, propane, isobutene, isobutane, n-butane, propyne, dienes and other C2+ hydrocarbon components, as well as solid particles, green oil, C6 ( C6+) and other impurity components such as water components, after a pretreatment process consisting of heat exchange, compression, dust removal, chlorine removal, oil removal, drying and refrigeration, other impurity components in the raw material gas are removed, and then enter the next process , Intercooler separation.

[0041] (2) In the intercooling separatio...

Embodiment 2

[0044] Such as figure 1 As shown, on the basis of Example 1, the feed gas contains 0.1 to 1.0% carbon dioxide (CO 2 ), the pretreatment process adds an alkali washing tower between the dust removal, chlorine removal, and oil removal sections and the drying section, and uses potassium hydroxide (KOH) lye containing 4 to 10% as a decarbonization absorbent to remove CO in the raw gas 2 Perform chemical absorption to remove CO 2 , and correspondingly increase the load of the subsequent drying tower.

Embodiment 3

[0046] Such as figure 1 As shown, on the basis of Example 1, the hydrogen-rich gas flowing out from the intercooling separation process is heat-exchanged to a shallow cooling temperature of 5-20°C, and enters the PSA hydrogen extraction process for hydrogen extraction. Vacuum step, and then flushing, pressure equalization boost and product hydrogen final filling, etc. A hydrogen product with a purity greater than or equal to 99.99% flows out from the top of the adsorption tower of the PSA system, and the yield of the hydrogen product is greater than or equal to 83-85%, wherein the total content of olefin impurity components is less than or equal to 0-5ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com