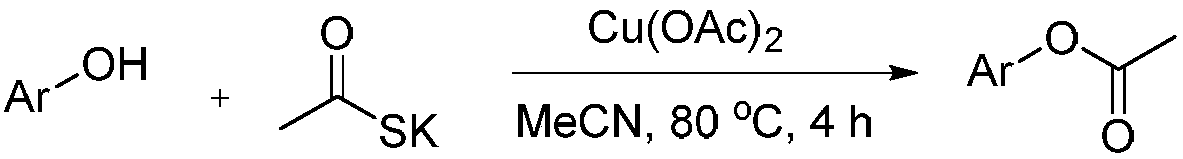

Method for synthesizing phenyl acetate derivatives

A technology of phenyl acetates and synthetic methods, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of expensive catalysts, restricting industrial development, and difficult storage, etc., and achieve substrate expansion Wide-ranging, lucrative, and easy-to-manage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

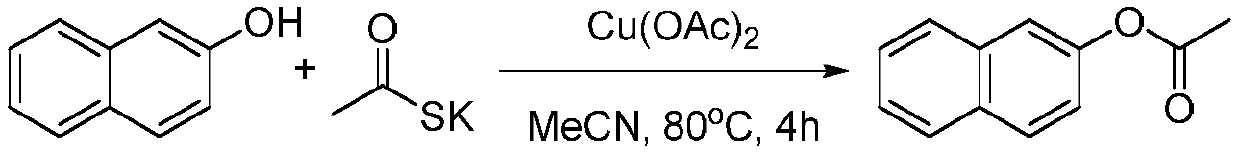

[0015] Embodiment 1: the synthesis of acetic acid-2-naphthyl ester

[0016]

[0017] Add β-naphthol (43.2 mg), potassium thioacetate (102.6 mg), Cu(OAc) to a 25 mL reaction tube 2 (12.0 mg), acetonitrile (2 mL), and magnetically stirred at 80° C. for 4 hours. After the reaction is finished, extract with ethyl acetate, collect the organic phase, evaporate most of the solvent under reduced pressure, and use petroleum ether: ethyl acetate (10:1) as eluent to carry out column chromatography for the remaining mixed solution. After purification, the target product was obtained as white needle crystals, 51 mg, yield 92%.

[0018] Its NMR data are as follows:

[0019] 1 H NMR (300MHz, CDCl 3 )δ=7.91~7.87(m,3H),7.61(s,1H),7.53-7.51(t,2H),7.30-7.27(t,3H),2.40(s,3H);

[0020] 13 C NMR (75MHz, CDCl 3 ) δ = 169.62, 146.70, 134.75, 128.15, 126.87, 126.39, 126.13, 125.50, 125.14, 121.22, 118.18, 21.09.

Embodiment 2

[0021] Embodiment 2: the synthesis of acetic acid-1-naphthyl ester

[0022]

[0023] Add α-naphthol (43.2 mg), potassium thioacetate (102.6 mg), Cu(OAc) to a 25 mL reaction tube 2 (12.0 mg), acetonitrile (2 mL), and magnetically stirred at 80° C. for 4 hours. After the reaction is finished, extract with ethyl acetate, collect the organic phase, evaporate most of the solvent under reduced pressure, and use petroleum ether: ethyl acetate (10:1) as eluent to carry out column chromatography for the remaining mixed solution. After purification, the target product was obtained as colorless needle crystals, 46 mg, and the yield was 83%.

[0024] Its NMR data are as follows:

[0025] 1 H NMR (300MHz, CDCl 3 )δ=7.93~7.91(m,2H), 7.81~7.78(m,1H), 7.58~7.49(m,3H), 7.31~7.29(d,1H), 2.51(s,3H);

[0026] 13 C NMR (75MHz, CDCl 3 ) δ = 169.78, 148.42, 133.85, 131.56, 129.53, 127.88, 127.75, 126.67, 125.82, 121.25, 118.65, 21.30.

Embodiment 3

[0027] Embodiment 3: the synthesis of acetic acid-2-methylphenyl ester

[0028]

[0029] Add o-cresol (32.4 mg), potassium thioacetate (102.6 mg), Cu(OAc) to a 25 mL reaction tube 2 (12.0 mg), acetonitrile (2 mL), and magnetically stirred at 80° C. for 4 hours. After the reaction is finished, extract with ethyl acetate, collect the organic phase, evaporate most of the solvent under reduced pressure, and use petroleum ether: ethyl acetate (10:1) as eluent to carry out column chromatography for the remaining mixed solution. After purification, the target product was obtained as a white solid, 27 mg, and the yield was 60%.

[0030] Its NMR data are as follows:

[0031] 1 H NMR (300MHz, CDCl 3 )δ=7.27~7.17(m,3H),7.03(d,J=7.6Hz,1H),2.35(d,J=2.5Hz,3H),2.2(s,3H);

[0032] 13 C NMR (75MHz, CDCl 3 ) δ = 169.37, 149.40, 131.20, 130.16, 127.00, 126.13, 121.92, 20.89, 16.20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com