Biochar improved material for soil remediation

A soil remediation and biochar technology, applied in the field of soil remediation, can solve problems such as poor soil remediation effect and inability to remediate heavy metal pollution in soil, and achieve the effects of improving heavy metal pollution, increasing water permeability, and reducing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

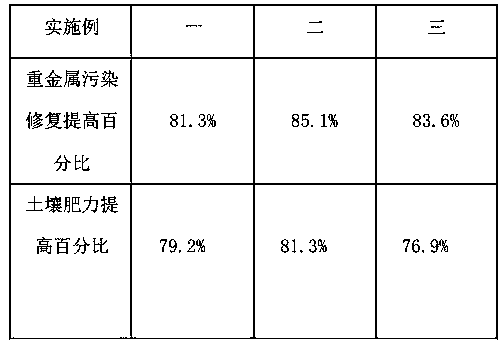

Examples

Embodiment 1

[0039] The present invention proposes a biochar improvement material for soil restoration, comprising the following raw materials in parts by weight: 20 parts of straw powder, 2 parts of quicklime, 25 parts of microbial agent, 30 parts of biochar, 2 parts of dipotassium hydrogen phosphate, ammonium sulfate 4 parts, 5 parts of organic silicon, 10 parts of lignin, 3 parts of quick-acting calcium, 5 parts of phosphate rock powder, 6 parts of amino acid, 5 parts of peat soil, 11 parts of diatomaceous earth, 1 part of humic acid, 7 parts of chitosan , 6 parts of activated carbon fiber, 5 parts of polyacrylamide, 3 parts of peat soil, 4 parts of organic fertilizer, 6 parts of sodium polyacrylate, 7 parts of Bacillus subtilis, 3 parts of citric acid, 2 parts of tartaric acid, 4 parts of oxalic acid, calcium chloride 3 parts, 6 parts of iron phosphate, 5 parts of saponin, 4 parts of rhizobia;

[0040] Its preparation method comprises the following steps:

[0041] S1: Put straw powder...

Embodiment 2

[0046] The present invention proposes a biochar improvement material for soil restoration, comprising the following raw materials in parts by weight: 25 parts of straw powder, 4 parts of quicklime, 30 parts of microbial agent, 35 parts of biochar, 3 parts of dipotassium hydrogen phosphate, ammonium sulfate 5 parts, 7 parts of organic silicon, 12 parts of lignin, 5 parts of quick-acting calcium, 7 parts of phosphate rock powder, 8 parts of amino acid, 7 parts of peat soil, 12 parts of diatomaceous earth, 2 parts of humic acid, 10 parts of chitosan , 8 parts of activated carbon fiber, 10 parts of polyacrylamide, 5 parts of peat soil, 6 parts of organic fertilizer, 9 parts of sodium polyacrylate, 10 parts of Bacillus subtilis, 5 parts of citric acid, 4 parts of tartaric acid, 6 parts of oxalic acid, calcium chloride 5 parts, 7 parts of iron phosphate, 9 parts of saponin, 6 parts of rhizobia;

[0047] Its preparation method comprises the following steps:

[0048] S1: Put straw po...

Embodiment 3

[0053] The present invention proposes a biochar improvement material for soil restoration, which includes the following raw materials in parts by weight: 30 parts of straw powder, 6 parts of quicklime, 35 parts of microbial agent, 40 parts of biochar, 5 parts of dipotassium hydrogen phosphate, ammonium sulfate 7 parts, 9 parts of organic silicon, 15 parts of lignin, 7 parts of available calcium, 9 parts of phosphate rock powder, 11 parts of amino acid, 10 parts of peat soil, 14 parts of diatomaceous earth, 4 parts of humic acid, 12 parts of chitosan , 10 parts of activated carbon fiber, 15 parts of polyacrylamide, 7 parts of peat soil, 9 parts of organic fertilizer, 13 parts of sodium polyacrylate, 12 parts of Bacillus subtilis, 7 parts of citric acid, 6 parts of tartaric acid, 8 parts of oxalic acid, calcium chloride 7 parts, 9 parts of iron phosphate, 11 parts of saponin, 8 parts of rhizobia;

[0054] Its preparation method comprises the following steps:

[0055] S1: Put st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com