Synthesis of high purity tungsten hexafluoride using metal tungsten as anodic electrolytic molten salt

A technology of tungsten hexafluoride and anode electrolysis, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of cumbersomeness, improving the purity of tungsten hexafluoride, and expensive production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

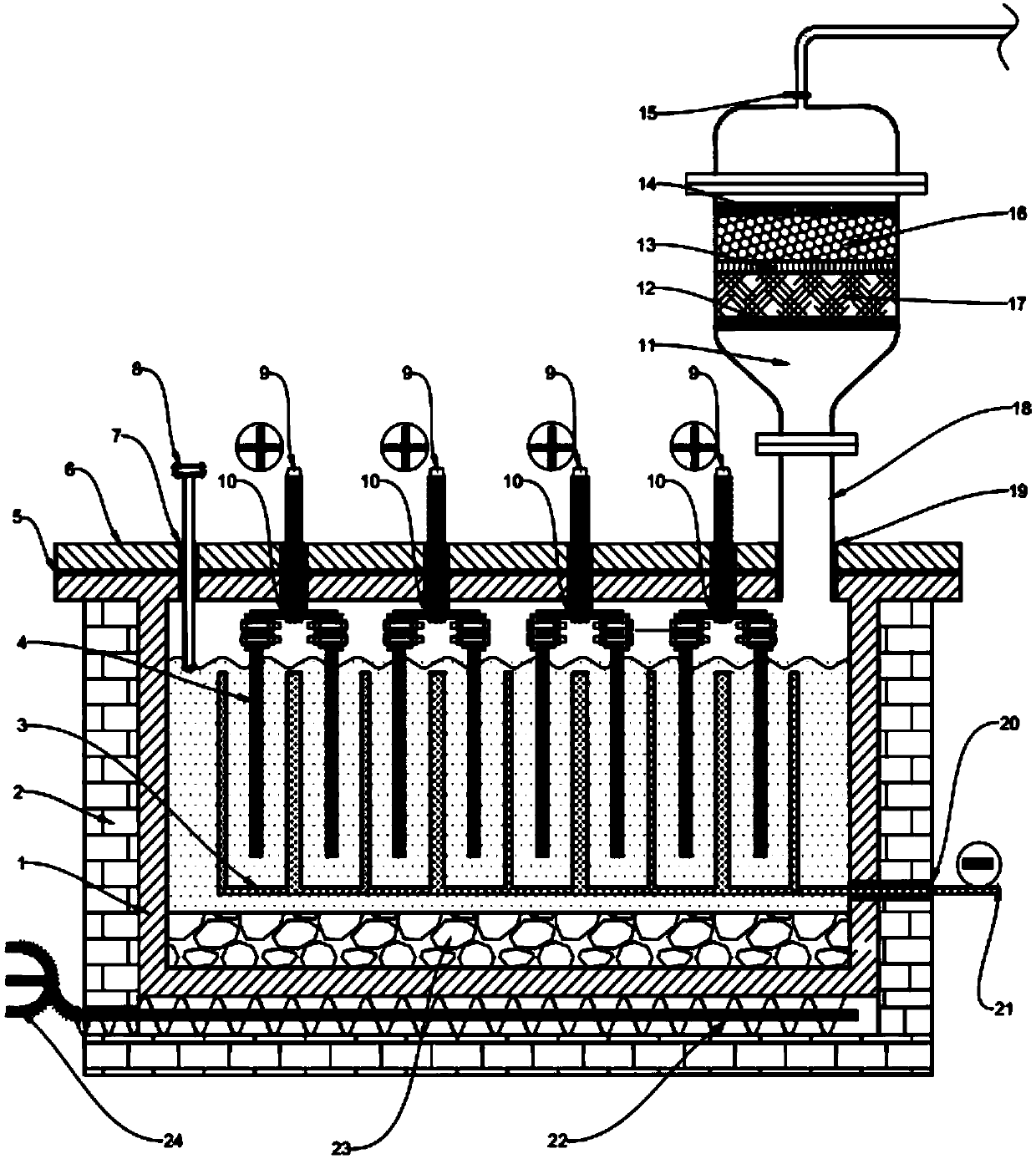

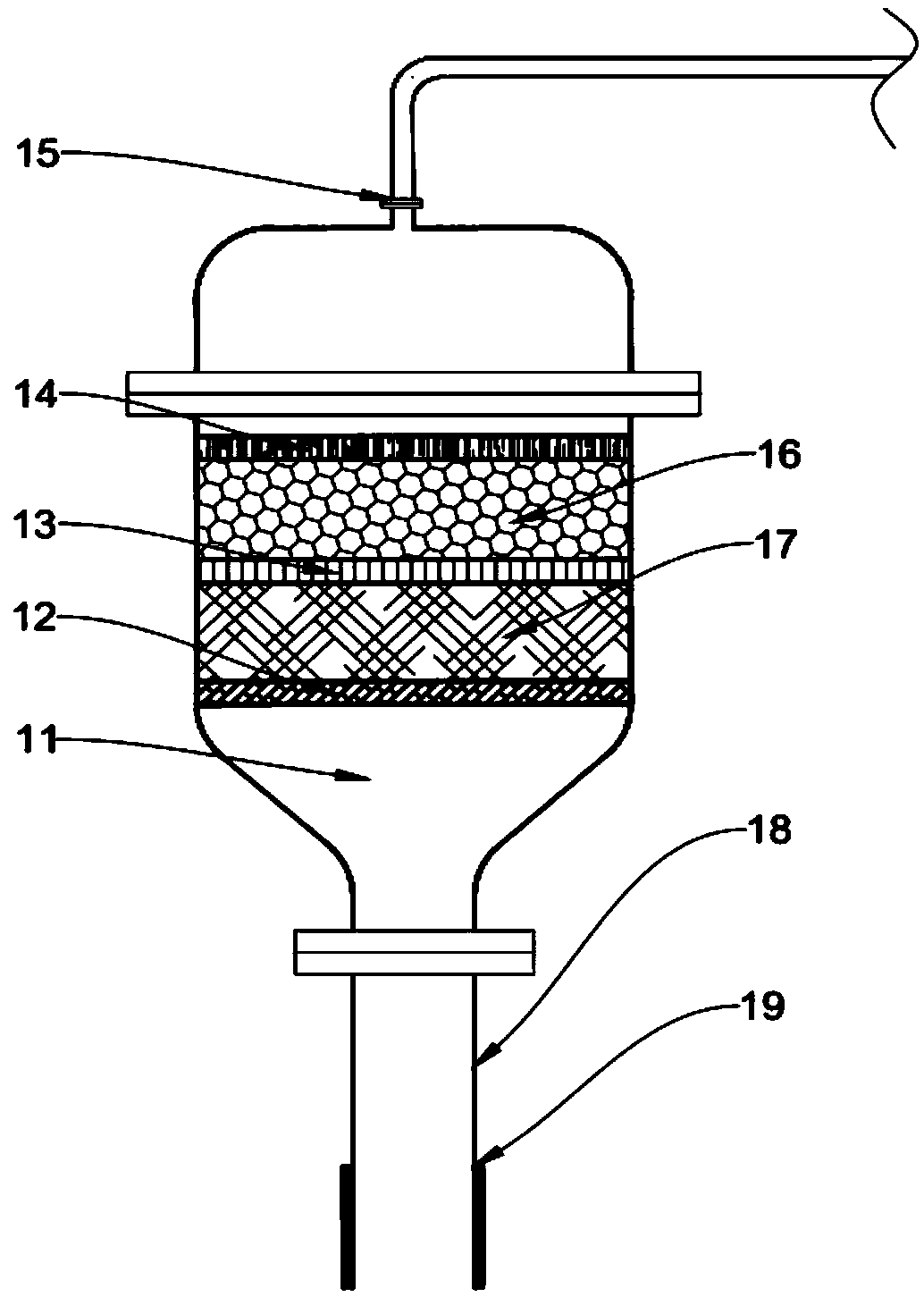

[0058] Metal tungsten is used as an anode to electrolyze molten salt to synthesize high-purity tungsten hexafluoride, including the following steps:

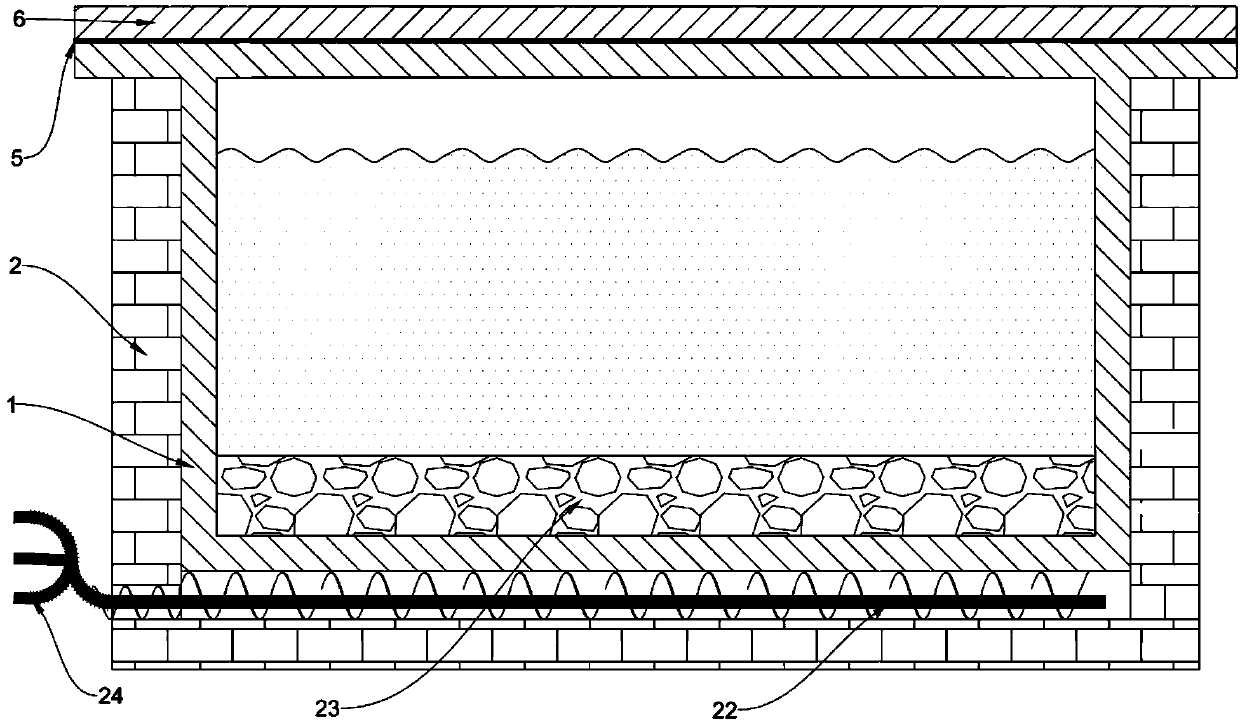

[0059] Select the DYD-100-0.5 type beryllium electrolytic cell as the core equipment prototype (basic parameters: electrolytic cell volume 0.8M 3 , the power of the intermediate frequency heating device is 100Kw, the overall material of the electrolytic tank is 3010 heat-resistant stainless steel, the thickness of the tank cover is 30mm, the thickness of the tank body is 18mm, the thickness of the light refractory brick insulation layer outside the tank is 200mm, the normal working temperature of the electrolytic tank: the highest resistance in a short period of time Heat 800°C, long-term work within 600°C, electrolytic cell cathode nickel plate size: 400*300*6*9, electrolytic cell anode tungsten plate size: 400*300*20*8,).

[0060] According to the requirements of the tooling, clean, degrease, assemble the cathode, anode, assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com